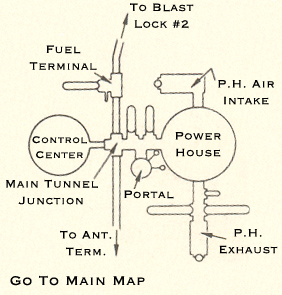

Air

Intake

With

four large generators to supply, the power house required an air

handling system that was a structure all unto itself. Connected

to the north hemisphere of the Power House's mezzanine level by a

9-foot 6-inch diameter tunnel, the filtration and conditioning

equipment was located in a 15-foot 6-inch diameter section oriented

perpendicular to the access tunnel.

|

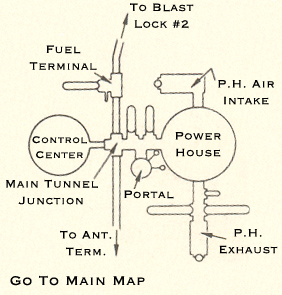

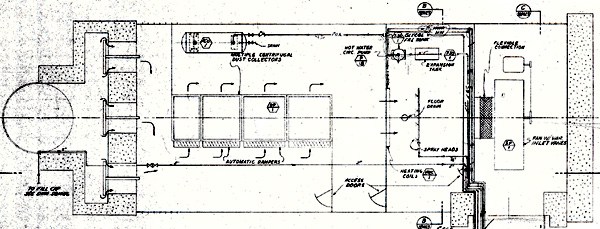

Power

House Air Filtration Facility - Top view

|

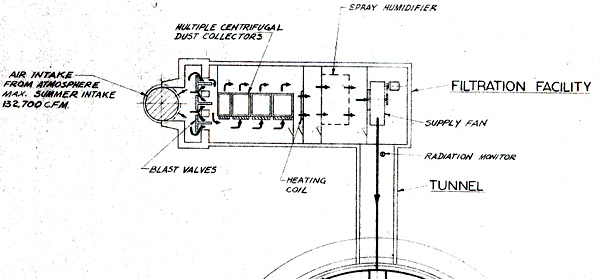

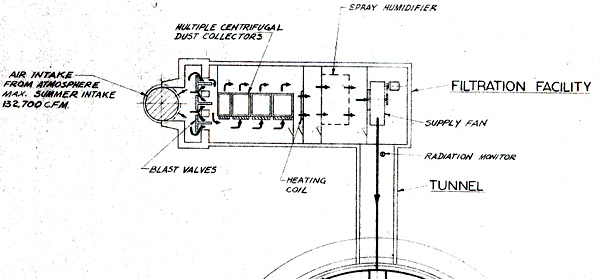

The

above diagram shows the airflow through the air intake facility-- it

descends about 30 feet from the surface and passes through the blast

valves (5 valves, each 60 inches in diameter) before entering the

filtration facility. The filtration facility is divided

longitudinally on the left half by a large plenum and array of

centrifugal dust collectors. The air would flow through the dust

collectors where it would be forced through small cylindrical channels

that would cause a vortex motion of the air which would precipitate

dust and other particles out so they would drop into a collection

hopper below as the air passed out the other side of the array.

|

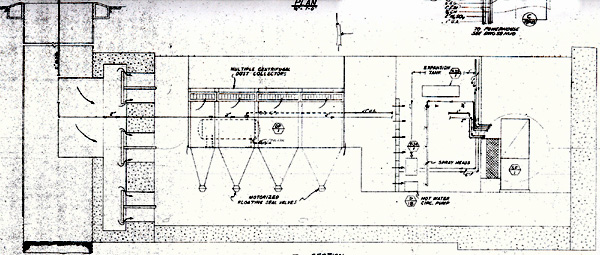

Power

House Air Filtration Facility - Top view detail

|

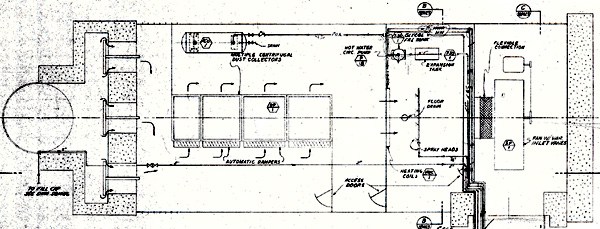

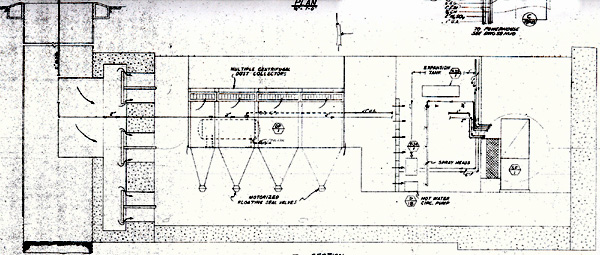

Once

on the other side of the dust collectors the partially filtered air

would pass through a large set of ethylene glycol heating coils over 2

stories high where it would be heated to around 55 degrees F if the

outside temperature was lower. Next the air would be humidified

by a sprayed coil humidifier which simply consisted of a series of 10

spray nozzles which added moisture to the incoming air.

|

Power

House Air Filtration Facility - Side aspect

|

From

the humidifier the air moved into a very large Trane Co. squirrel cage

fan with variable inlet vanes to control the rate of flow. This

fan forced the air into the Power House and the generators at a

maximum rate of 132,700 cubic feet per minute.

|

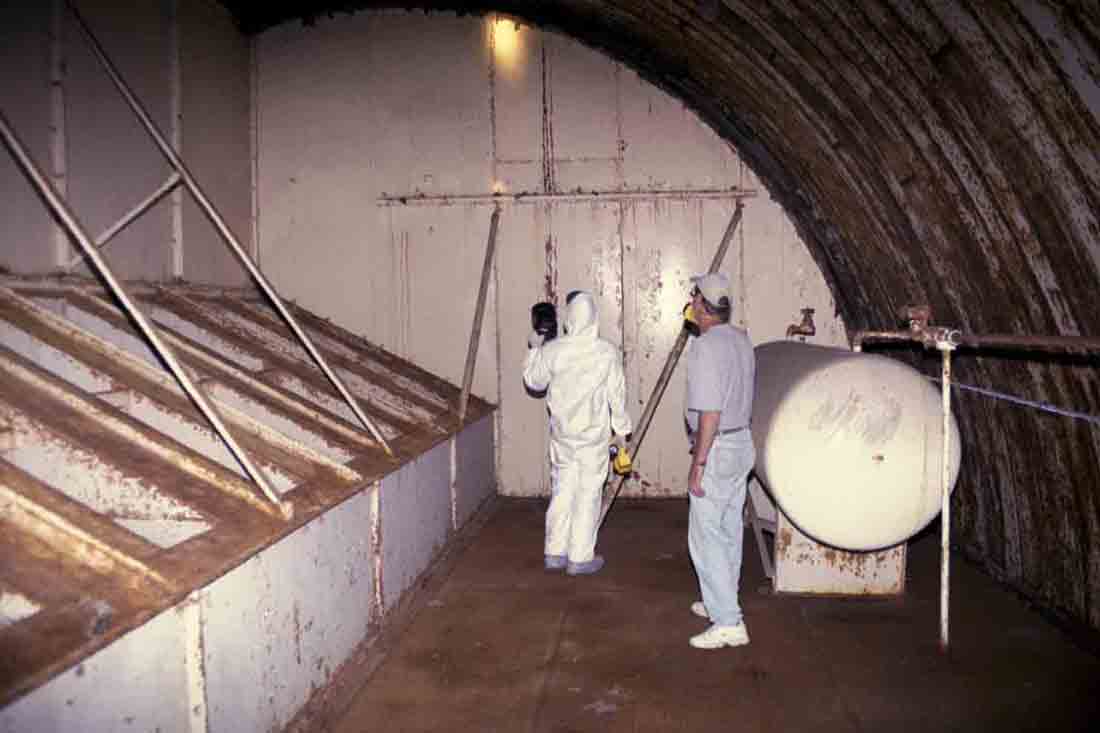

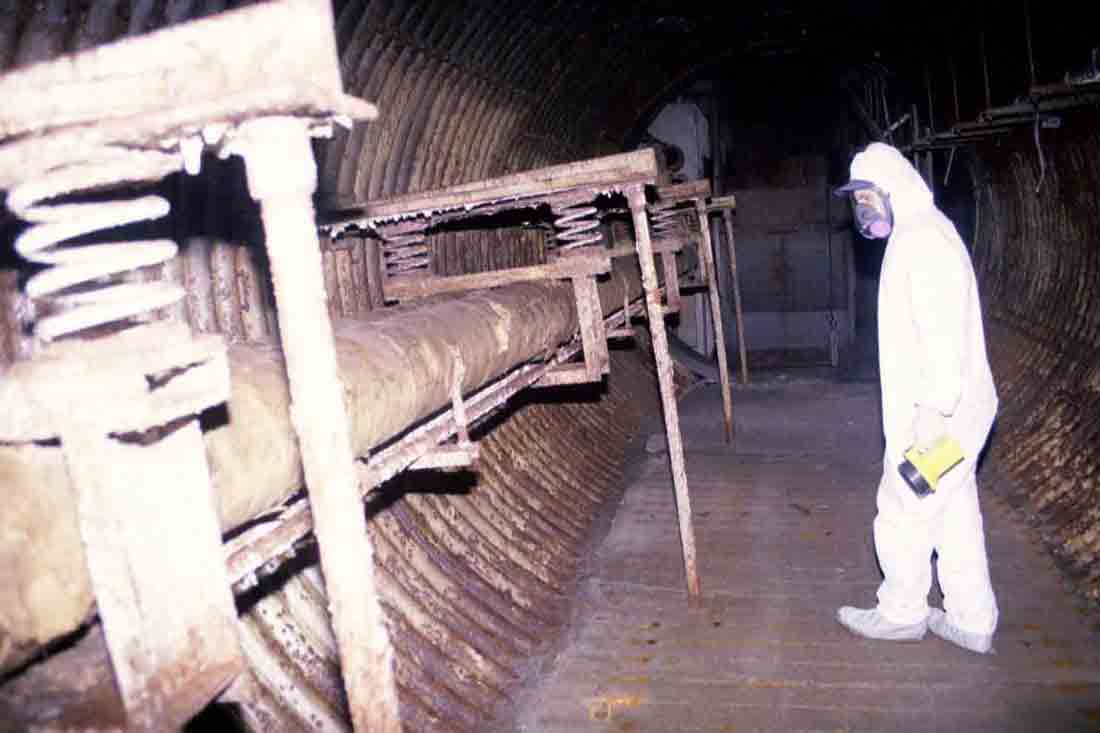

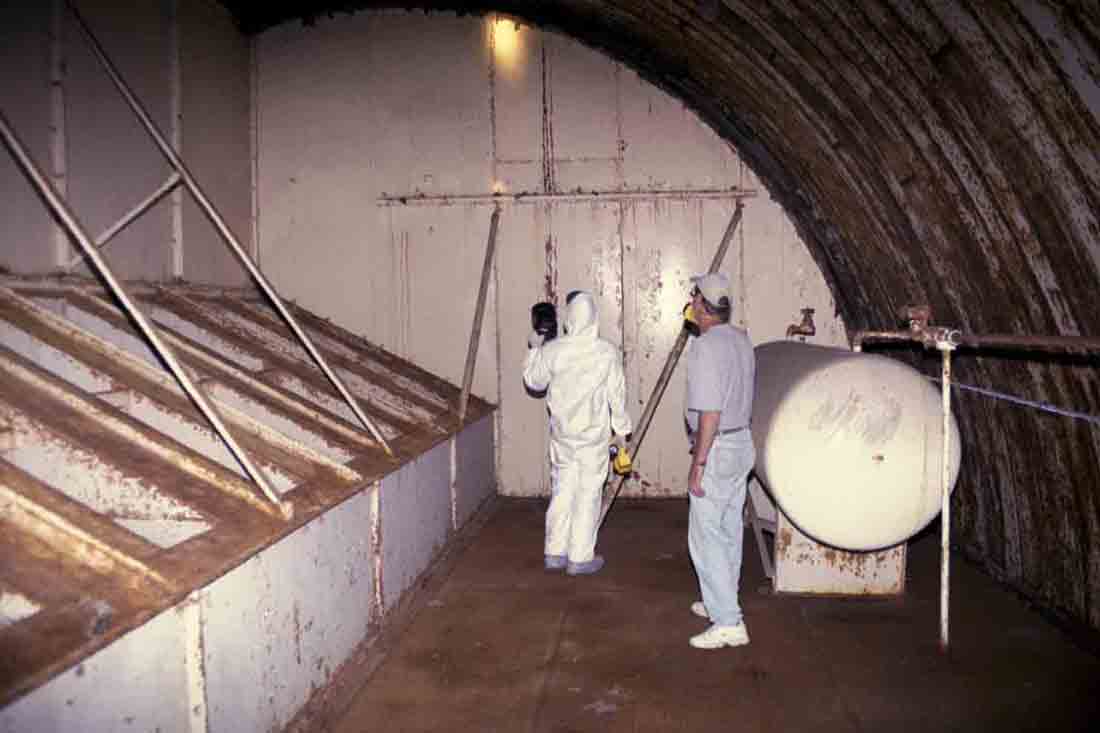

Construction

photo of the Power House filtration facility showing the slanted

cyclonic dust collector array and the 60" blast valves before the corrugated

liner was emplaced. The Control Center dome is visible toward the

upper right and the 30,000 gallon raw water tanks are located just

behind the figure walking in the center of the photo.

|

|

Silo

Gnome inspects some shock-mounted ethylene glycol lines in the tunnel

connecting the Power House and the filtration facility. A very

large fan is visible at the end of the tunnel where the structure heads

90 degrees off to the left.

|

Since

the first 2 Titan bases were constructed in Colorado, (or squadrons if

you prefer. Martin Co. designated the Lowry sites as T-1 in their

documentation) there were many design modifications in the later Titan

facilities. The largest physical change in the Titan complexes

built in California, South Dakota, Idaho and Washington was in the Power

House air intake and exhaust facilities. The

air intake and exhaust facilities were changed from a predominantly

horizontal configuration to a vertical stack which comprised far less

space and materials with a more efficient design. I have been

unable to see this design difference for myself. I have seen a few

photos taken during site remediation by the US Army of Engineers, but

they are dreadfully low quality and there are precious few of

them. If anyone has any good pictures of the air handling

structures from the other bases I'd be very appreciative if they could

contact me.

|

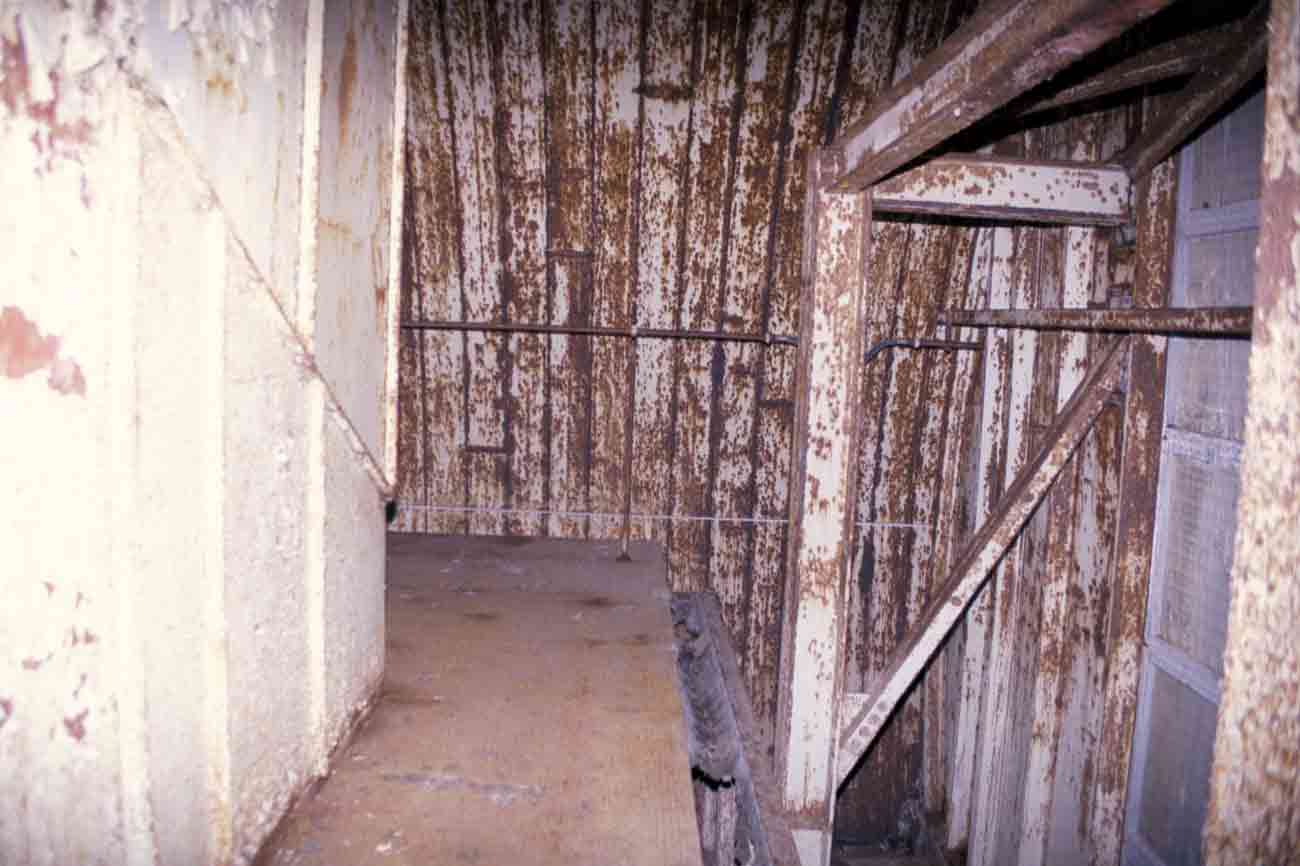

Looking toward the Power

House from inside the filtration facility's connecting tunnel. The

lines here are ethylene glycol supply and return lines used to heat

incoming the air.

Looking toward the Power

House from inside the filtration facility's connecting tunnel. The

lines here are ethylene glycol supply and return lines used to heat

incoming the air.

|

On

an odd side note I am rather interested in the Trane equipment at the

Titan sites. The fan in these pictures were manufactured at the

Trane facility in LaCrosse Wisconsin and shipped to Denver by

railcar. The reason for my interest is that I had an uncle who was

employed as a welder at the LaCrosse plant during the 60's and 70's (now

deceased, may he rest in peace) and I cannot help wondering if he took

part in the fabrication of some of the very large air handling equipment

installed at the Titan I sites.

|

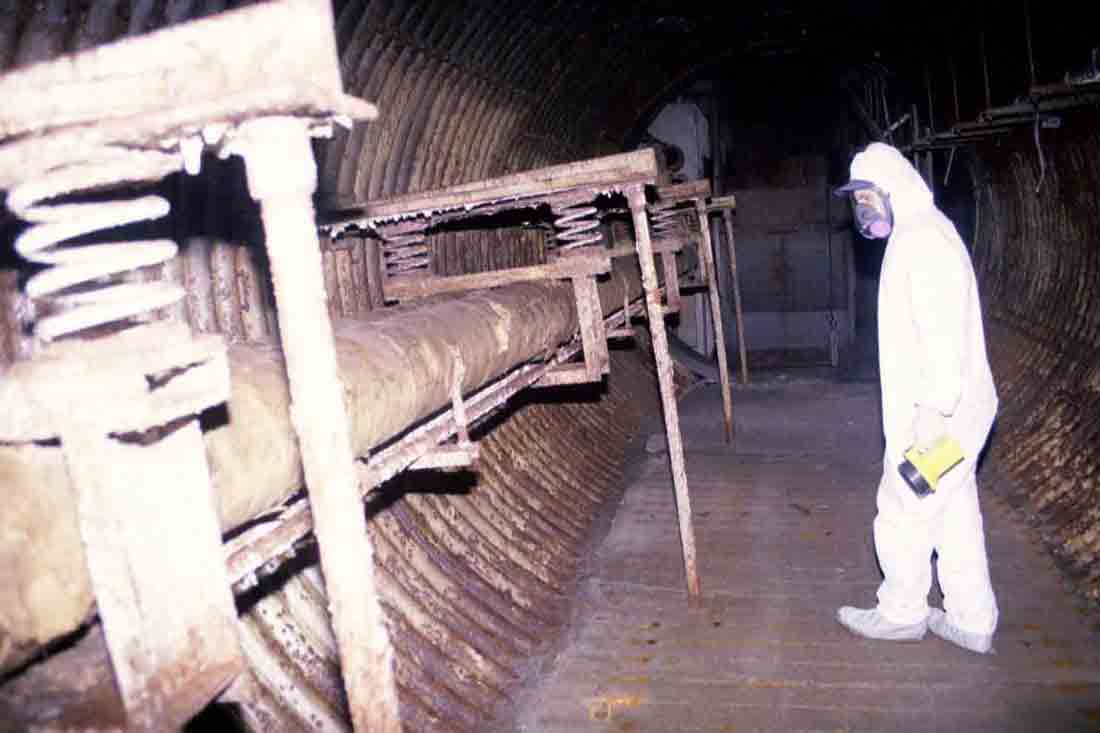

Standing beside the Trane

Co. squirrel cage fan in full mesothelioma-resistant gear I am

dwarfed. I happen to be just shy of 6 feet tall, so I estimate

this unit to stand around 13 feet tall! The sheave (where the

drive belts run) takes an impressive 9 belts so I know this fan is no

lightweight. Interestingly, the bearings still moved smoothly and

easily by hand even after 40 years.

Standing beside the Trane

Co. squirrel cage fan in full mesothelioma-resistant gear I am

dwarfed. I happen to be just shy of 6 feet tall, so I estimate

this unit to stand around 13 feet tall! The sheave (where the

drive belts run) takes an impressive 9 belts so I know this fan is no

lightweight. Interestingly, the bearings still moved smoothly and

easily by hand even after 40 years.

|

Just

beyond this point a radiation monitor would detect incoming fallout if

it entered the complex. If detected, an indicator would light on

the facilities console in the Control Center indicating radiation in the

Power House, alerting the crew to close the blast valves.

Detectors were also located in the Launcher Air Filtration Facility, the

Control Center and on the surface to alert the crew of a radiation

hazard existing outside the complex.

The

entire platform supporting the fan, heat exchanger, expansion tank,

large drive motor and other equipment was suspended in a large steel

framework such that it "floated". This was both for

shock-mounting and vibration damping, but produced some interesting and

unintended effects.

|

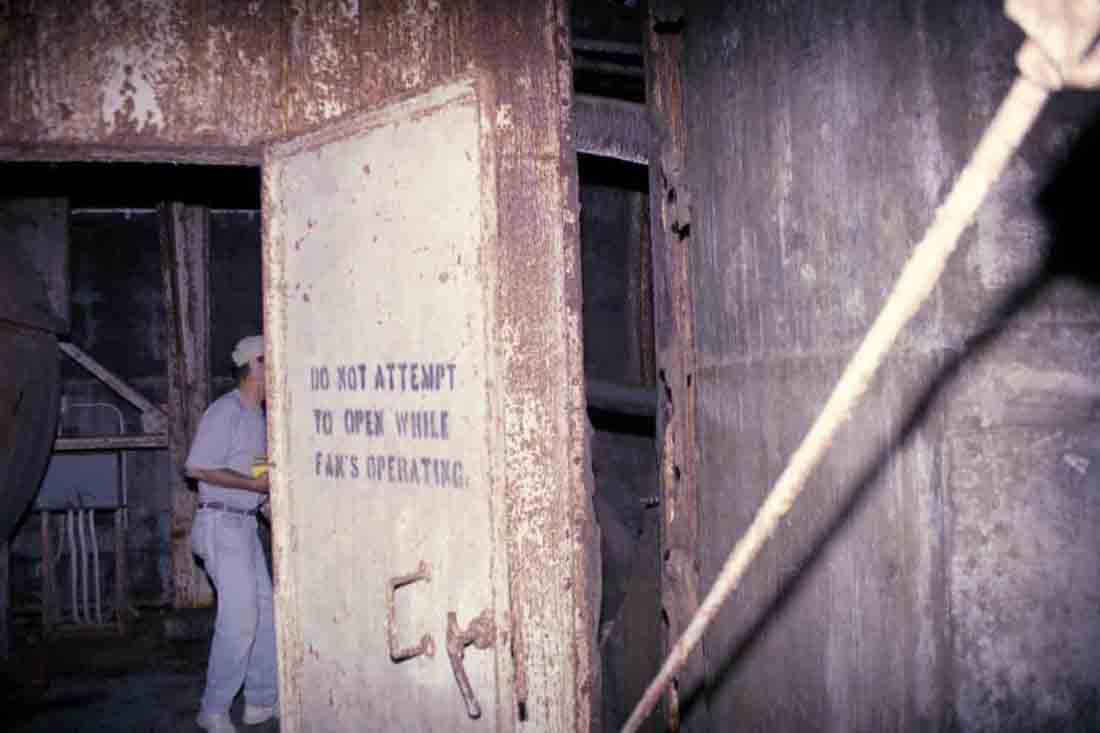

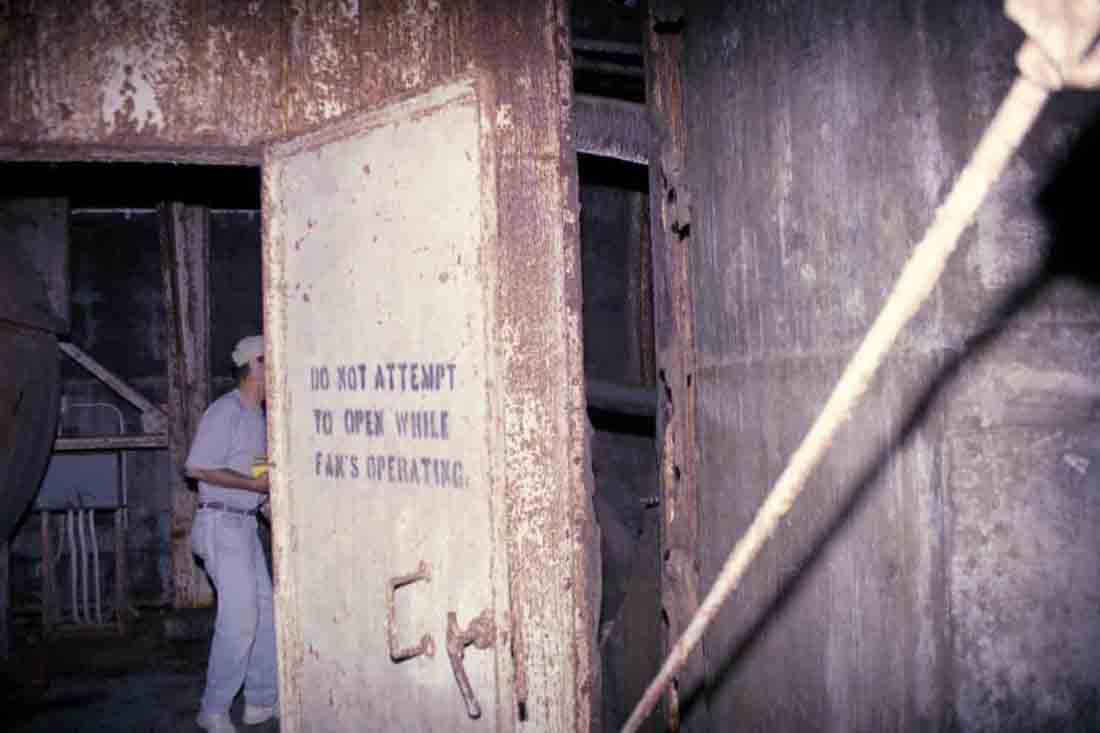

Looking from the fan area

into the humidification and heating area. The door's warning is

certainly valid as there would be tremendous pressure on it with the fan

running. To open this door under pressure would be a great way to

have your teeth/nose knocked in. The humidity in this area has

greatly accelerated the oxidation and decay of metal and seals.

The neoprene seal which used to occupy the space in the middle of the

photo has disintegrated almost completely in contrast with the mostly

intact seals found in the rest of the complex.

Looking from the fan area

into the humidification and heating area. The door's warning is

certainly valid as there would be tremendous pressure on it with the fan

running. To open this door under pressure would be a great way to

have your teeth/nose knocked in. The humidity in this area has

greatly accelerated the oxidation and decay of metal and seals.

The neoprene seal which used to occupy the space in the middle of the

photo has disintegrated almost completely in contrast with the mostly

intact seals found in the rest of the complex.

|

On

windy days (the majority of days in the area of the Lowry complexes) air

forced down through the intake tunnel would pass through the structure

and set the large steel plenums and threaded struts (one is visible in

the above photo) to resonating. The resulting vibration produced a

very disconcerting and eerie low thrumming sound that would make your

hair stand on end. That's precisely what it did the first time I

heard it along with a tour group who was visiting 1-C for the first

time. We all froze and listened as a deep rumble reverberated

inside the dome of the Power House's ceiling like a huge machine coming

to life. It sounded as though the Titan was waking up around us!

After

thoroughly soiling ourselves we tried to locate the source of the spooky

noise and traced it to the filtration facility where we found the steel

supports and walls vibrating like strings on a bass fiddle. The

tunnels and warrens of the Titan complex make excellent conduits for

channeling sound it turns out.

|

The heating coils, which

stand nearly 16 feet in height. These were heated by hot water

from the Power House boilers which passed through a heat

exchanger. Air flow would be from the perspective of this photo

and through the coils. The personnel access door is visible at the

lower right.

The heating coils, which

stand nearly 16 feet in height. These were heated by hot water

from the Power House boilers which passed through a heat

exchanger. Air flow would be from the perspective of this photo

and through the coils. The personnel access door is visible at the

lower right.

|

That

deep serenade in the Power House wasn't the first time the acoustic

properties of the Titan had freaked me out. Years earlier I was

working to clean dirt, rust, paint chips and other filth out of the

Entry Portal stairway using an industrial HEPA vac. The vacuum

looked like an overgrown shop vac and made a hell of a racket as I

worked my way down the dark steps cleaning up 40 years' work of crud. It

was deafening in there with the vac on so I had foam earplugs crammed in

my skull to preserve what hearing I had, and I was wearing a full-face

respirator and full body suit. I looked suspiciously like the silo

gnome in some of the pictures in fact. Despite the plugs, I could

still hear the vacuum running quite well. As

I toiled in the area of the revolving security door, the vacuum seemed to

start making a strange noise and changed pitch. Using my

handyman's repertoire, I soundly beat the vacuum with my hand hoping to

rectify the trouble. When this method failed I switched off the

unit to inspect it. To my surprise the industrial roar of the

vacuum did not stop. Puzzled,

I flipped the switch on and off several times, but the sound persisted,

which confused me greatly. I felt the vacuum; it was not vibrating

so it had to be off. I stood up and removed my earplugs and the

sound became much louder with a deep thumping that I could feel in

my chest! "What

the hell?" I said, heading up the steps to the surface. The

more I ascended, the louder the sound became and the more pronounced the

staccato pressures buffeted me. I

emerged on the surface in time for about 4 Black Hawk helicopters (undoubtedly

from nearby Buckley Air National Guard) to fly

low right over the complex and myself. Dressed as I was, I am not

sure who was more surprised. It's not every day you see a guy

dressed like that pop out of the ground! It

was really surprising how well the sound of the choppers channeled its

way down into the complex. I must have been hearing them from more

than 10 miles off before I went topside, and then it was through the

sound of an industrial vacuum and earplugs while 16 feet underground and

surrounded by concrete!

|

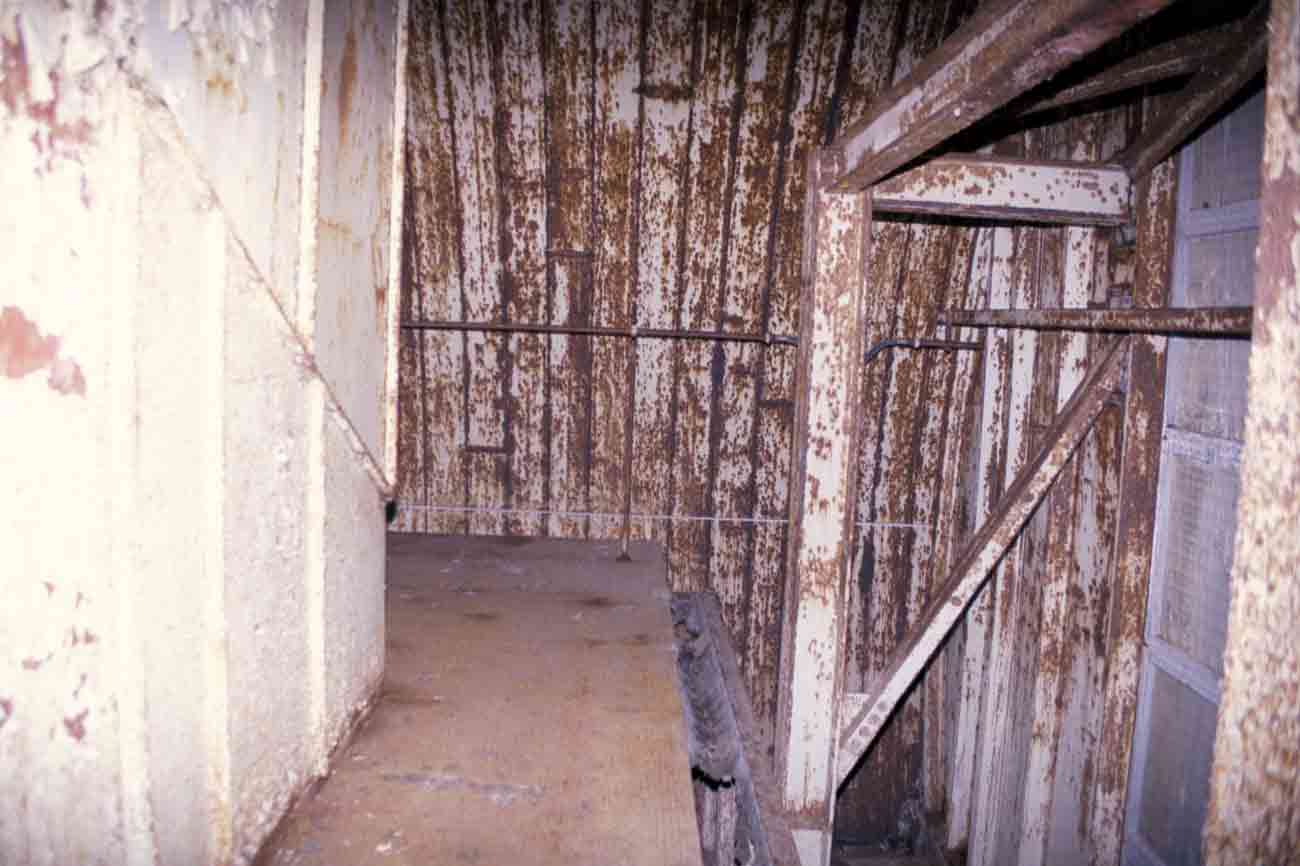

View from between the dust collectors

(left) and the heating coils (at right).

View from between the dust collectors

(left) and the heating coils (at right).

|

|

This side of the filtration

facility is where air enters the cyclonic dust separators through the

dampers at the right. The Blast valves are visible at the

end. This platform is about 7 feet above the lower level where the

dust collector's hoppers could be serviced. The lower level at

site 724-C was at different times flooded or mired with very nasty

mud. Needless to say I never ventured below.

This side of the filtration

facility is where air enters the cyclonic dust separators through the

dampers at the right. The Blast valves are visible at the

end. This platform is about 7 feet above the lower level where the

dust collector's hoppers could be serviced. The lower level at

site 724-C was at different times flooded or mired with very nasty

mud. Needless to say I never ventured below.

|

Back

on track! The blast valves were still open, but despite the urge

to try to pass thru them to the other side, both a long drop and a moat

of nasty water stood between me and my curiosity. I've also been

told that the valves are also under tremendous spring pressure and there

is no guarantee that disturbing them to squeeze through would not cause

them to snap shut. Not a pretty picture.

|

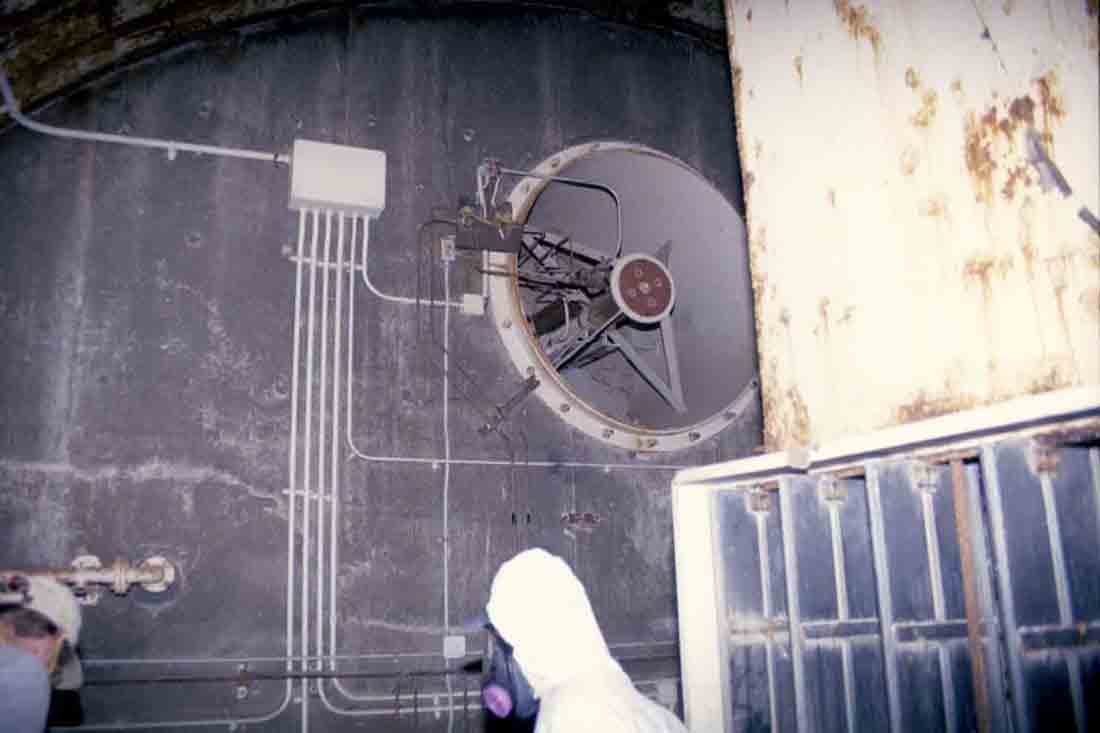

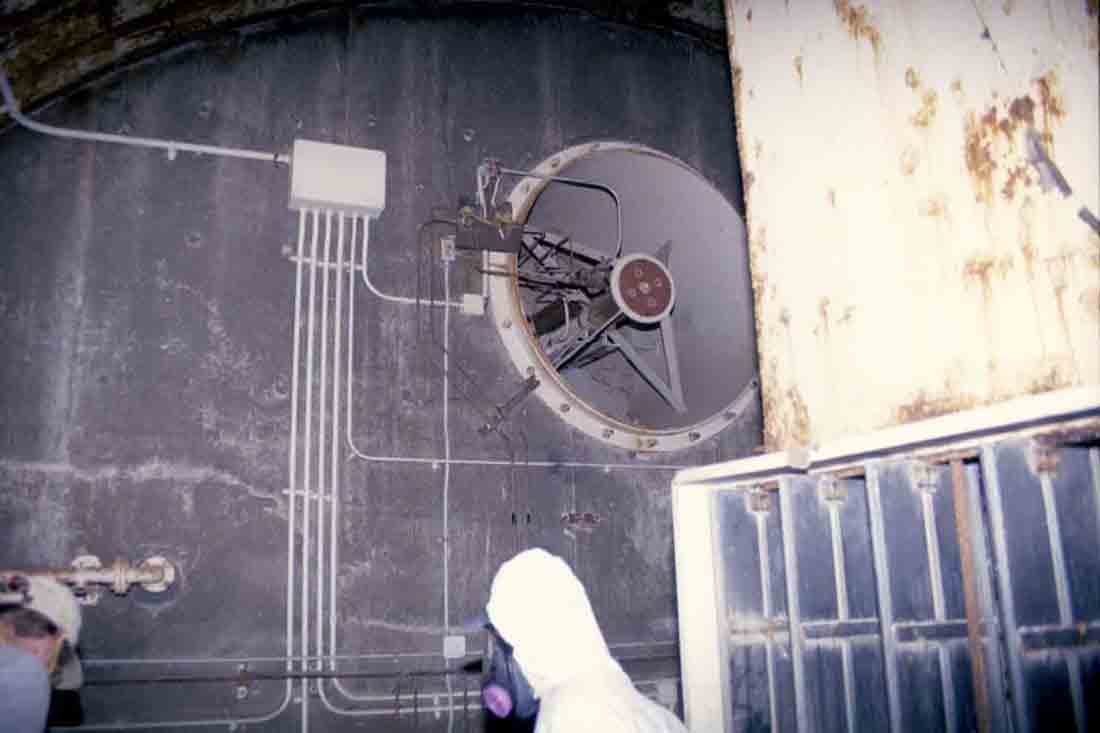

A better view of one of the blast valves.

There exists a gap of about 8' or more between the platform on which we

stood in this picture and the concrete firewall through which the blast

valves penetrate. The gap, which had several feet of water at the

bottom, made for an effective deterrent to keep us from messing with the

spring-loaded valves. This picture gives an idea of the

thickness of the concrete slab which protects the interior of the

complex.

A better view of one of the blast valves.

There exists a gap of about 8' or more between the platform on which we

stood in this picture and the concrete firewall through which the blast

valves penetrate. The gap, which had several feet of water at the

bottom, made for an effective deterrent to keep us from messing with the

spring-loaded valves. This picture gives an idea of the

thickness of the concrete slab which protects the interior of the

complex.

|

Apparently,

there's not much to see in the air intake shaft anyway-- its simply a

corrugated steel liner and a few service conduits running to the

surface. At 724-C, the Power House intake and exhaust shafts have

been sealed over using what appears to be scrap steel salvage from the

complex to keep intruders out. A large "cap" covers the

approximately 65' deep shaft, which has water of an indeterminate depth

at the bottom. Depending on the season, this water spills over

into the filtration facility through the blast valves and makes its way

into the Power House and down the two deep wells at the bottom of the

pipe trench.

|

Another view of the firewall

and a blast valve. On the left you can see a 2" sulfuric acid

(H2SO4) fill line which runs to one of the many

tanks comprising the process water system in the Power House. This

also shows the effective aforementioned "gap" we were loathe

to try and cross.

Another view of the firewall

and a blast valve. On the left you can see a 2" sulfuric acid

(H2SO4) fill line which runs to one of the many

tanks comprising the process water system in the Power House. This

also shows the effective aforementioned "gap" we were loathe

to try and cross.

|

|

One more look at a 60"

blast valve. This is the center valve with four more valves

arranged at each compass point around it.

One more look at a 60"

blast valve. This is the center valve with four more valves

arranged at each compass point around it.

|

|

This is the exit side of the

dust collectors (at left) and is closed off from the blast valves.

These tall steel walls or plenums which achieved this separation are in

large part what was creating the unsettling vibrations and sounds

detailed earlier in this section. A large utility air pressure

accumulator tank was located here for keeping pressure on the humidification

spray heads and probably supplied the pneumatic dampers and inlet vane

controls as well.

This is the exit side of the

dust collectors (at left) and is closed off from the blast valves.

These tall steel walls or plenums which achieved this separation are in

large part what was creating the unsettling vibrations and sounds

detailed earlier in this section. A large utility air pressure

accumulator tank was located here for keeping pressure on the humidification

spray heads and probably supplied the pneumatic dampers and inlet vane

controls as well.

|

Air

flow moved up out of the dust collectors and on to the heating coils and

humidification spray heads before being forced onward to the Power House

by the fan and consumed by the generators and supplying the remaining

structure with fresh air. me

of the sites were turned over to the original landowners; some sites

remained government property until most were sold at auction along with

abandoned Atlas sites and other surplus military property.

From

here you can head back to the Power House,

check out the Power House Exhaust,

return to the Main Tunnel Junction

(T.J.#10) or visit other points of interest using the map

below:

Current

Location: Power House Air Intake

|

Where

would you like to go next?

|

|

Contact

| Site Map | Links |

Hosted by

InfoBunker

|

Looking toward the Power

House from inside the filtration facility's connecting tunnel. The

lines here are ethylene glycol supply and return lines used to heat

incoming the air.

Looking toward the Power

House from inside the filtration facility's connecting tunnel. The

lines here are ethylene glycol supply and return lines used to heat

incoming the air. Standing beside the Trane

Co. squirrel cage fan in full mesothelioma-resistant gear I am

dwarfed. I happen to be just shy of 6 feet tall, so I estimate

this unit to stand around 13 feet tall! The sheave (where the

drive belts run) takes an impressive 9 belts so I know this fan is no

lightweight. Interestingly, the bearings still moved smoothly and

easily by hand even after 40 years.

Standing beside the Trane

Co. squirrel cage fan in full mesothelioma-resistant gear I am

dwarfed. I happen to be just shy of 6 feet tall, so I estimate

this unit to stand around 13 feet tall! The sheave (where the

drive belts run) takes an impressive 9 belts so I know this fan is no

lightweight. Interestingly, the bearings still moved smoothly and

easily by hand even after 40 years. Looking from the fan area

into the humidification and heating area. The door's warning is

certainly valid as there would be tremendous pressure on it with the fan

running. To open this door under pressure would be a great way to

have your teeth/nose knocked in. The humidity in this area has

greatly accelerated the oxidation and decay of metal and seals.

The neoprene seal which used to occupy the space in the middle of the

photo has disintegrated almost completely in contrast with the mostly

intact seals found in the rest of the complex.

Looking from the fan area

into the humidification and heating area. The door's warning is

certainly valid as there would be tremendous pressure on it with the fan

running. To open this door under pressure would be a great way to

have your teeth/nose knocked in. The humidity in this area has

greatly accelerated the oxidation and decay of metal and seals.

The neoprene seal which used to occupy the space in the middle of the

photo has disintegrated almost completely in contrast with the mostly

intact seals found in the rest of the complex. The heating coils, which

stand nearly 16 feet in height. These were heated by hot water

from the Power House boilers which passed through a heat

exchanger. Air flow would be from the perspective of this photo

and through the coils. The personnel access door is visible at the

lower right.

The heating coils, which

stand nearly 16 feet in height. These were heated by hot water

from the Power House boilers which passed through a heat

exchanger. Air flow would be from the perspective of this photo

and through the coils. The personnel access door is visible at the

lower right. View from between the dust collectors

(left) and the heating coils (at right).

View from between the dust collectors

(left) and the heating coils (at right). This side of the filtration

facility is where air enters the cyclonic dust separators through the

dampers at the right. The Blast valves are visible at the

end. This platform is about 7 feet above the lower level where the

dust collector's hoppers could be serviced. The lower level at

site 724-C was at different times flooded or mired with very nasty

mud. Needless to say I never ventured below.

This side of the filtration

facility is where air enters the cyclonic dust separators through the

dampers at the right. The Blast valves are visible at the

end. This platform is about 7 feet above the lower level where the

dust collector's hoppers could be serviced. The lower level at

site 724-C was at different times flooded or mired with very nasty

mud. Needless to say I never ventured below. A better view of one of the blast valves.

There exists a gap of about 8' or more between the platform on which we

stood in this picture and the concrete firewall through which the blast

valves penetrate. The gap, which had several feet of water at the

bottom, made for an effective deterrent to keep us from messing with the

spring-loaded valves. This picture gives an idea of the

thickness of the concrete slab which protects the interior of the

complex.

A better view of one of the blast valves.

There exists a gap of about 8' or more between the platform on which we

stood in this picture and the concrete firewall through which the blast

valves penetrate. The gap, which had several feet of water at the

bottom, made for an effective deterrent to keep us from messing with the

spring-loaded valves. This picture gives an idea of the

thickness of the concrete slab which protects the interior of the

complex. Another view of the firewall

and a blast valve. On the left you can see a 2" sulfuric acid

(H2SO4) fill line which runs to one of the many

tanks comprising the process water system in the Power House. This

also shows the effective aforementioned "gap" we were loathe

to try and cross.

Another view of the firewall

and a blast valve. On the left you can see a 2" sulfuric acid

(H2SO4) fill line which runs to one of the many

tanks comprising the process water system in the Power House. This

also shows the effective aforementioned "gap" we were loathe

to try and cross. One more look at a 60"

blast valve. This is the center valve with four more valves

arranged at each compass point around it.

One more look at a 60"

blast valve. This is the center valve with four more valves

arranged at each compass point around it. This is the exit side of the

dust collectors (at left) and is closed off from the blast valves.

These tall steel walls or plenums which achieved this separation are in

large part what was creating the unsettling vibrations and sounds

detailed earlier in this section. A large utility air pressure

accumulator tank was located here for keeping pressure on the humidification

spray heads and probably supplied the pneumatic dampers and inlet vane

controls as well.

This is the exit side of the

dust collectors (at left) and is closed off from the blast valves.

These tall steel walls or plenums which achieved this separation are in

large part what was creating the unsettling vibrations and sounds

detailed earlier in this section. A large utility air pressure

accumulator tank was located here for keeping pressure on the humidification

spray heads and probably supplied the pneumatic dampers and inlet vane

controls as well.