|

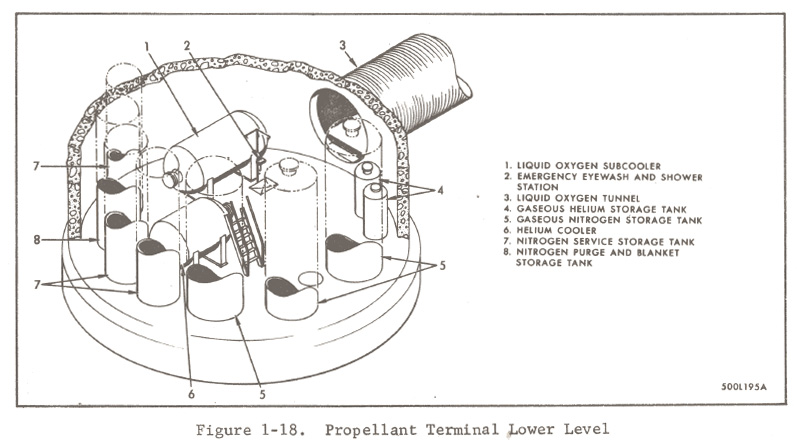

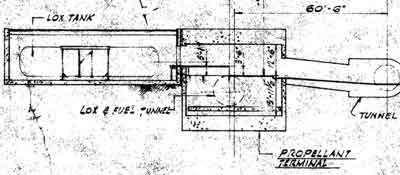

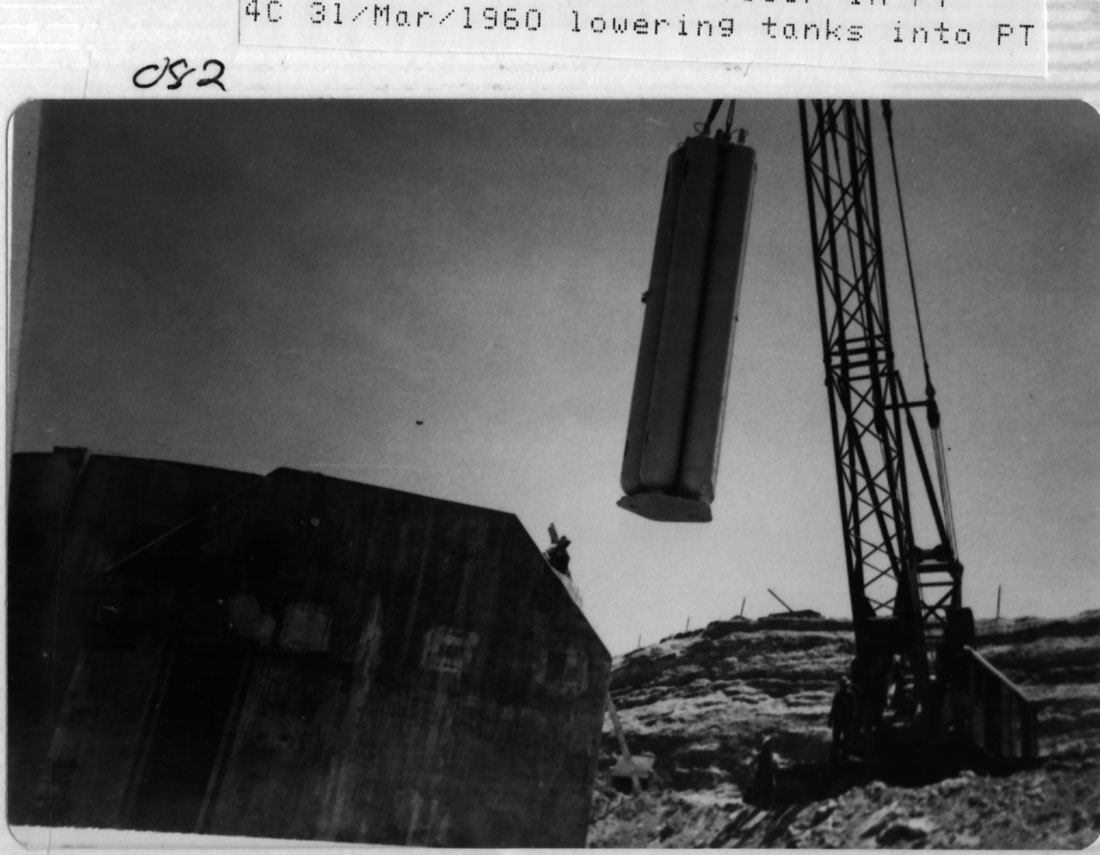

Propellant

Terminal - Side aspect

|

|

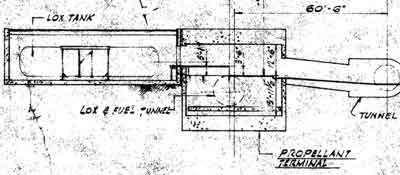

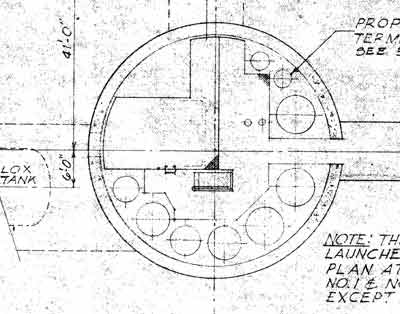

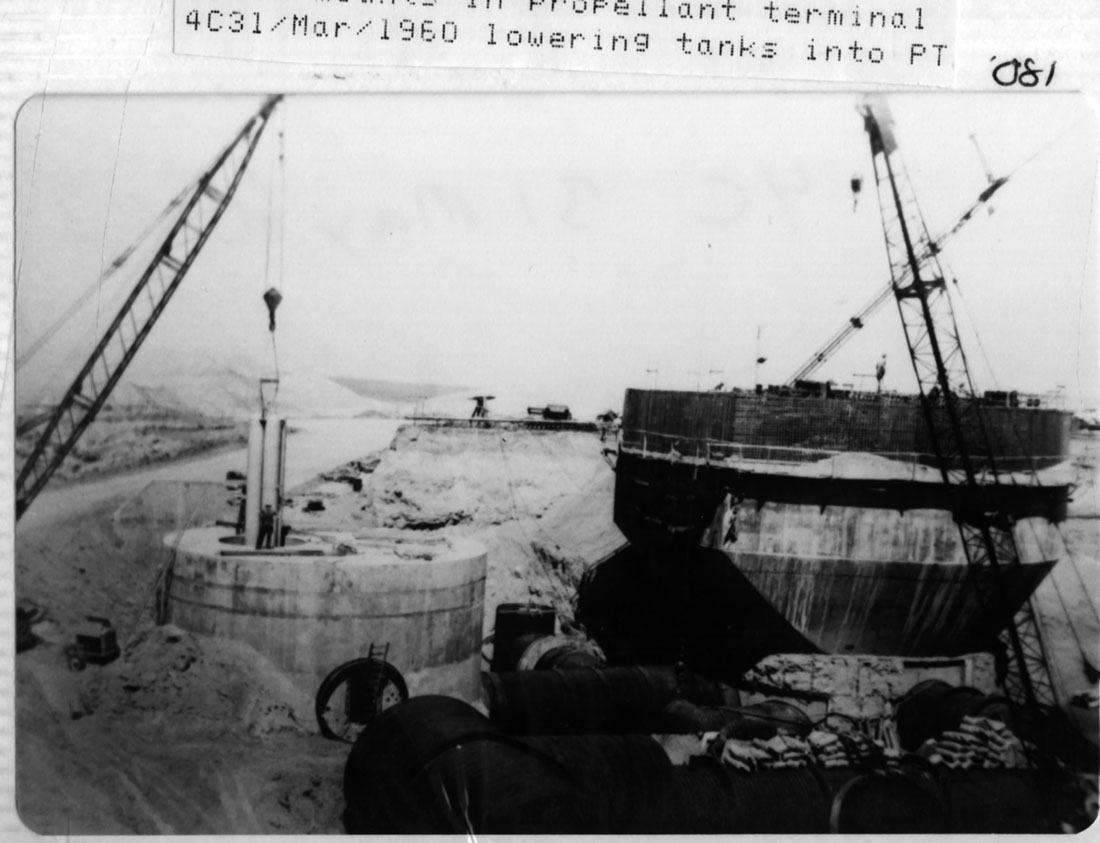

Propellant

Terminal - Top-down view

|

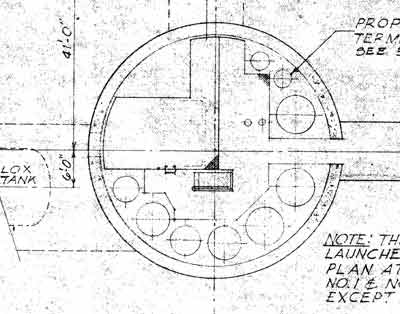

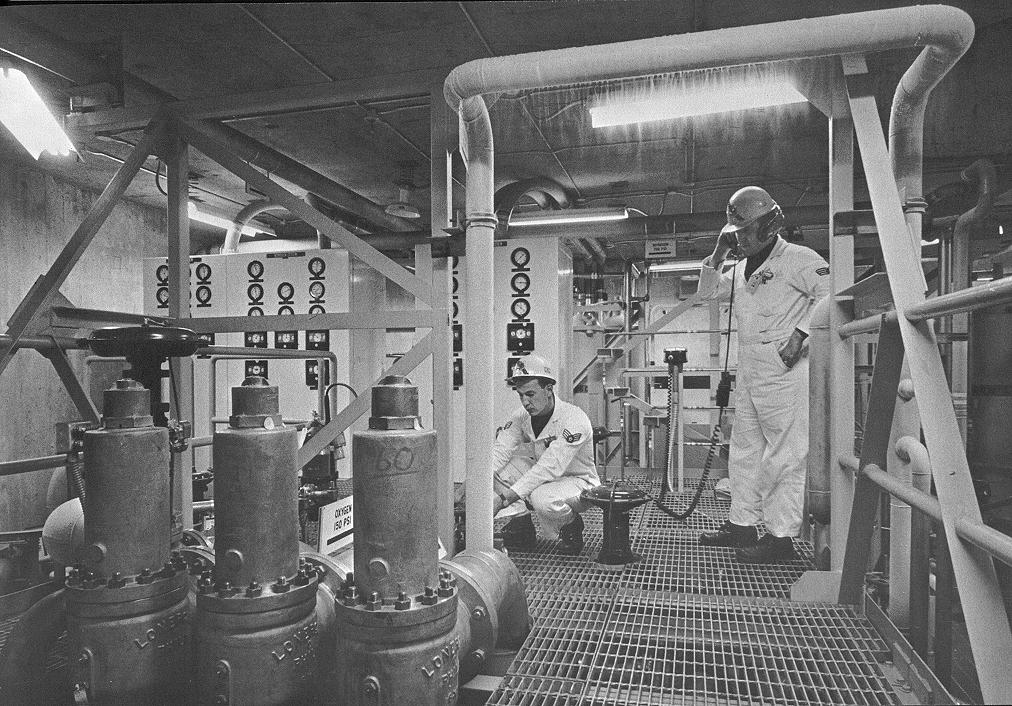

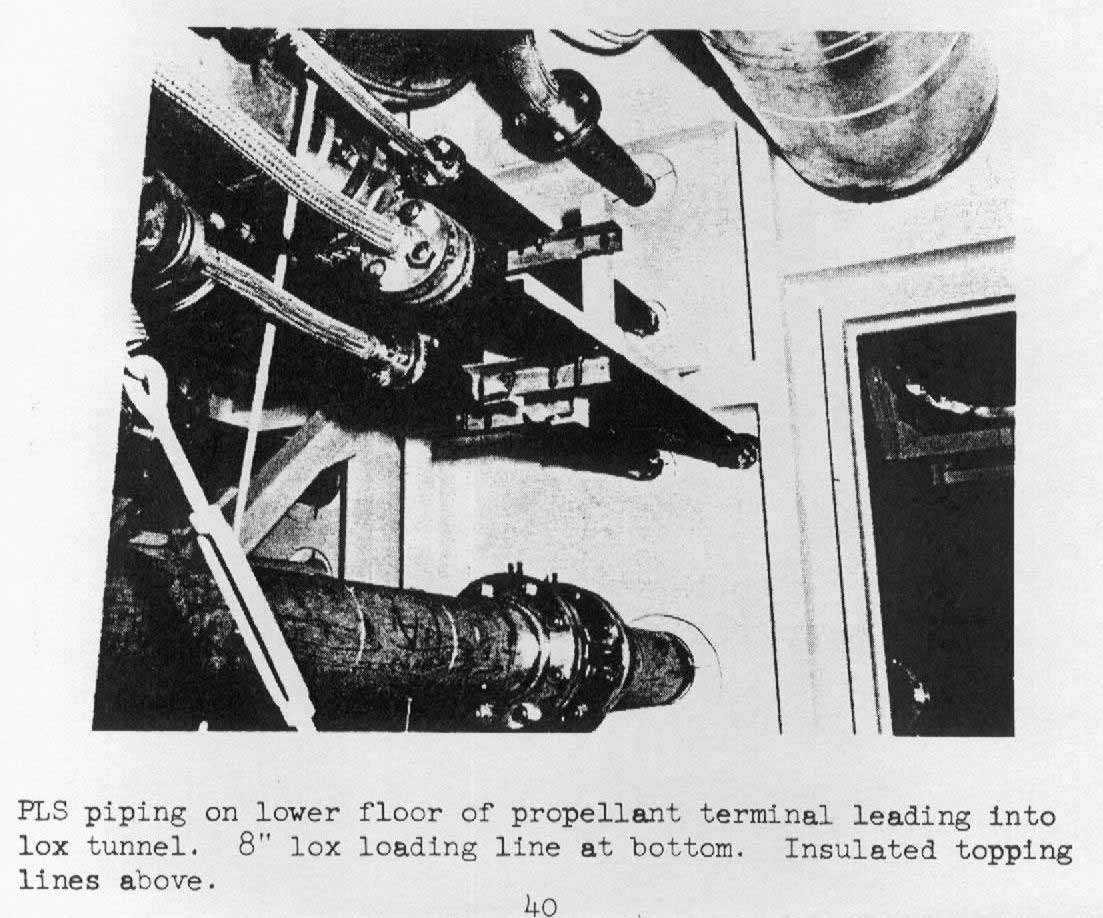

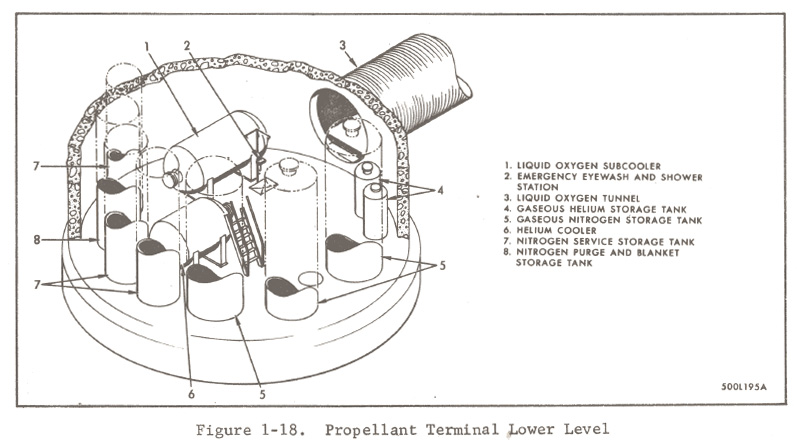

The

propellant terminal is another cylindrical structure, 37'6" in

diameter, 2 stories high with reinforced concrete walls 18" thick

used to store liquid oxygen (LOX), liquid and gaseous nitrogen and

helium as well as equipment for controlling the transfer of these

gasses from their storage tanks to the missile and to support

equipment.

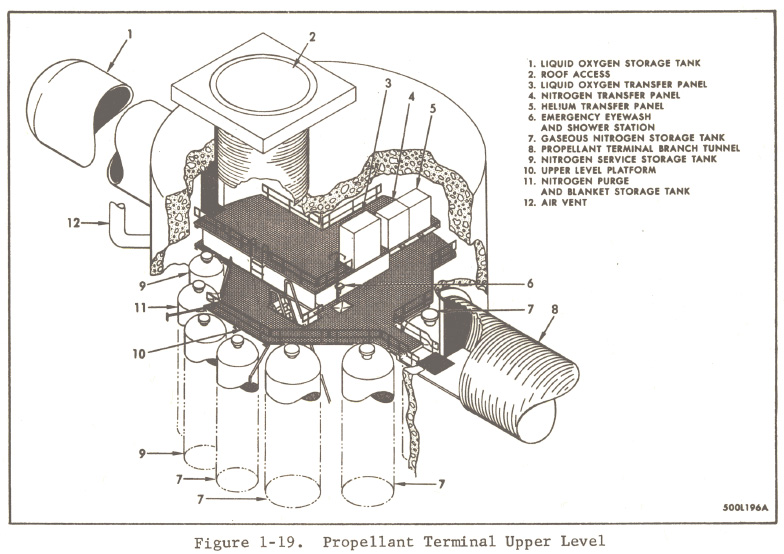

The

upper level contained the LOX, nitrogen and helium transfer panels, and

the lower level contained a helium cooler and LOX sub cooler and

various vacuum pumps for the coolers. The whole terminal was filled

with non-reactive stainless steel plumbing for transfer of the volatile

liquids and gasses along with standard steel and

other piping for compressed air and water.

|

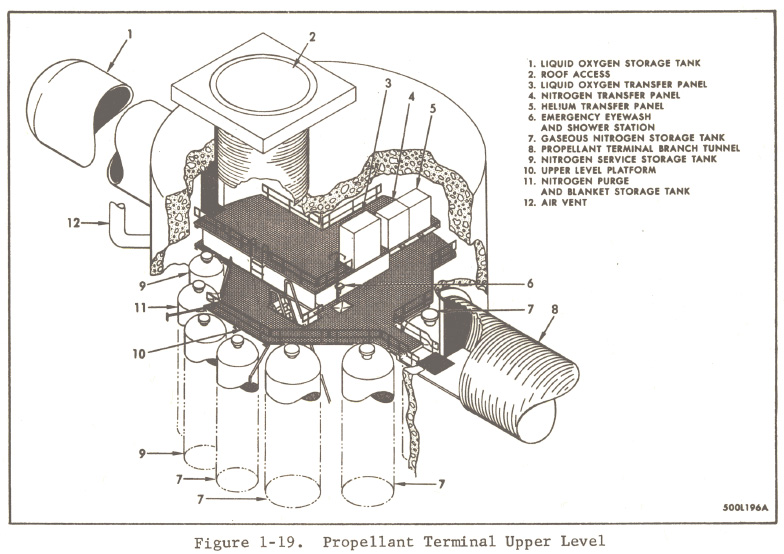

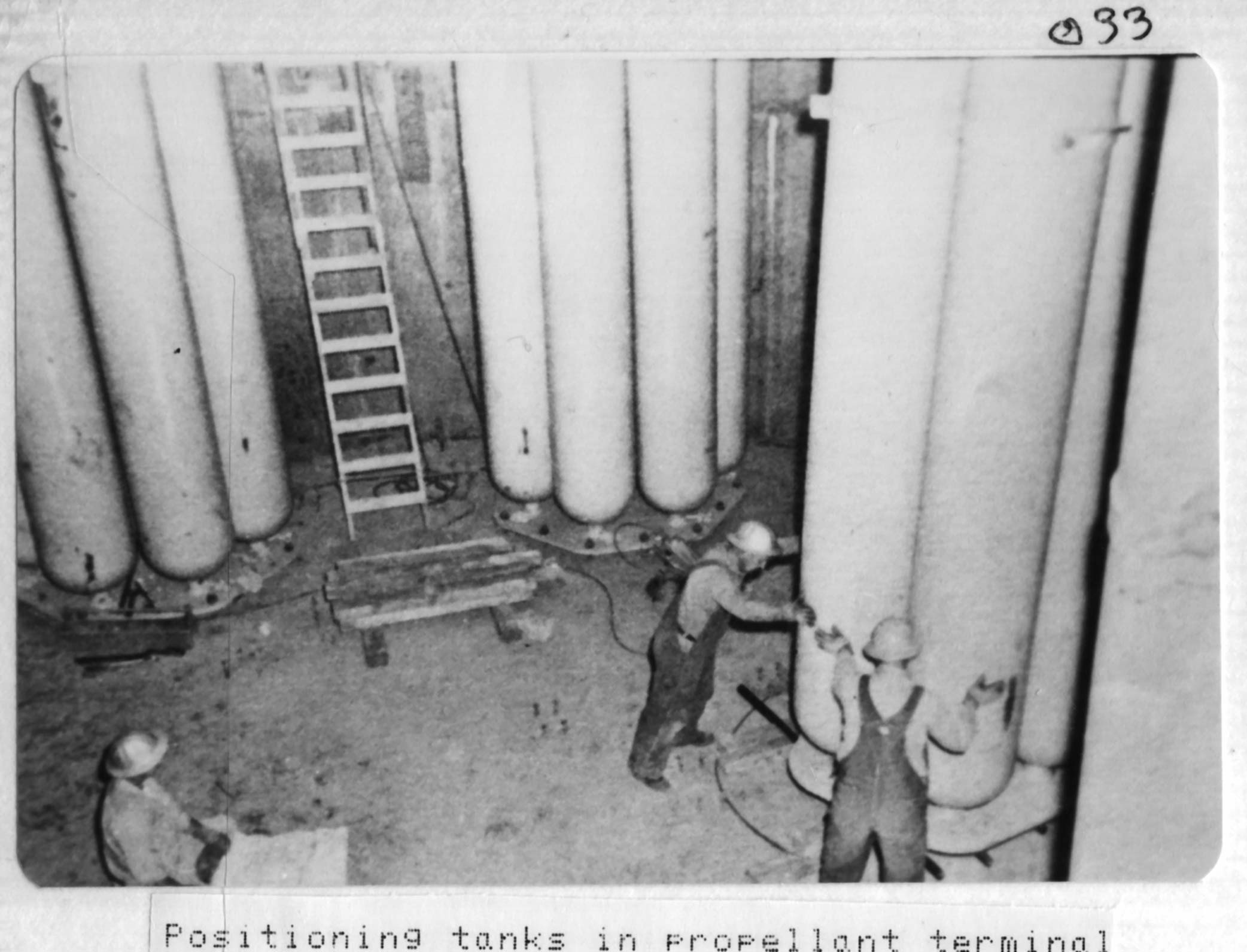

Upper

level - Each of the upright tanks in the illustrations are actually an

array of 4, 6 or 7 gas cylinders

|

|

Lower

level - The LOX sub-cooler and other storage tanks and piping occupied

the lower level

|

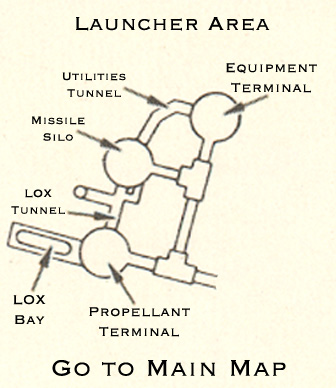

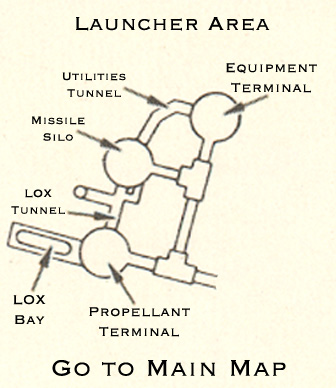

The

propellant terminal is connected to the missile silo by the LOX tunnel

on the lower level and to the LOX bay containing the LOX storage tank

on the upper level. The LOX

tunnel in turn is connected to the LOX loading and vent shaft that

runs to the surface.

The

LOX tunnel routed the LOX lines from the propellant terminal to the

missile and its oxidizer tanks and also carried helium and nitrogen to

the silo and the missile.

The

LOX bay contained the double-walled stainless steel LOX tank suspended

in a giant steel cradle designed to attenuate the transfer of ground

shocks to the pressurized vessel containing the thousands of gallons

(each tank had a capacity of 28,000 gallons) of oxidizer for that

particular launcher silo.

|

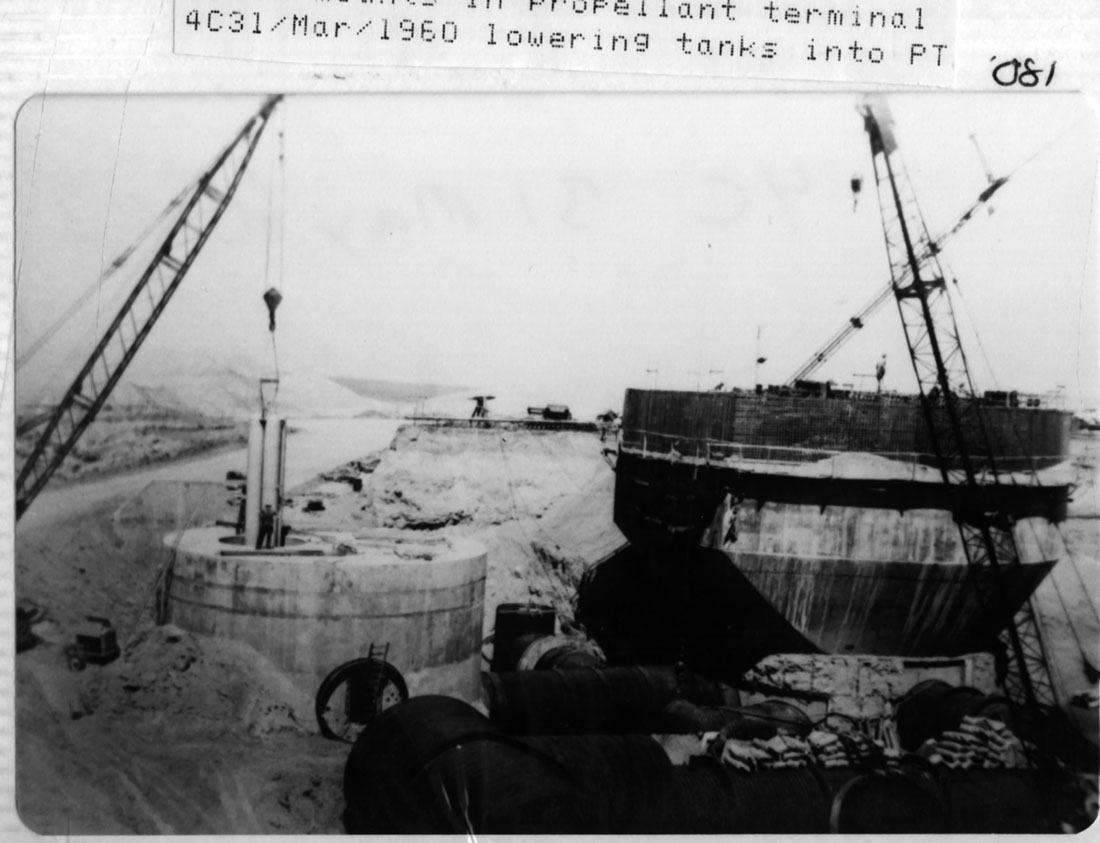

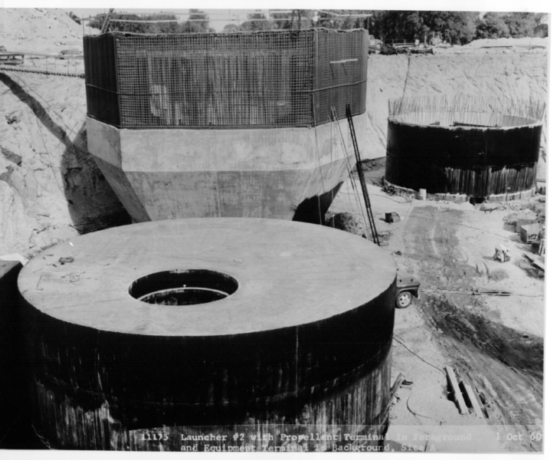

One

of the launcher areas under construction prior to backfilling.

The propellant terminal in the foreground with the launcher silo in back

and the equipment terminal in the upper right.

Note

the thickness of the concrete roof visible at the circular access

portal.

|

|

View

of the propellant terminal with the LOX bay visible on the left.

The LOX tank and connections can also be seen here. At this stage

the interconnecting tunnels to the launcher area have yet to be

installed.

Photo

courtesy of Fred Epler

|

|

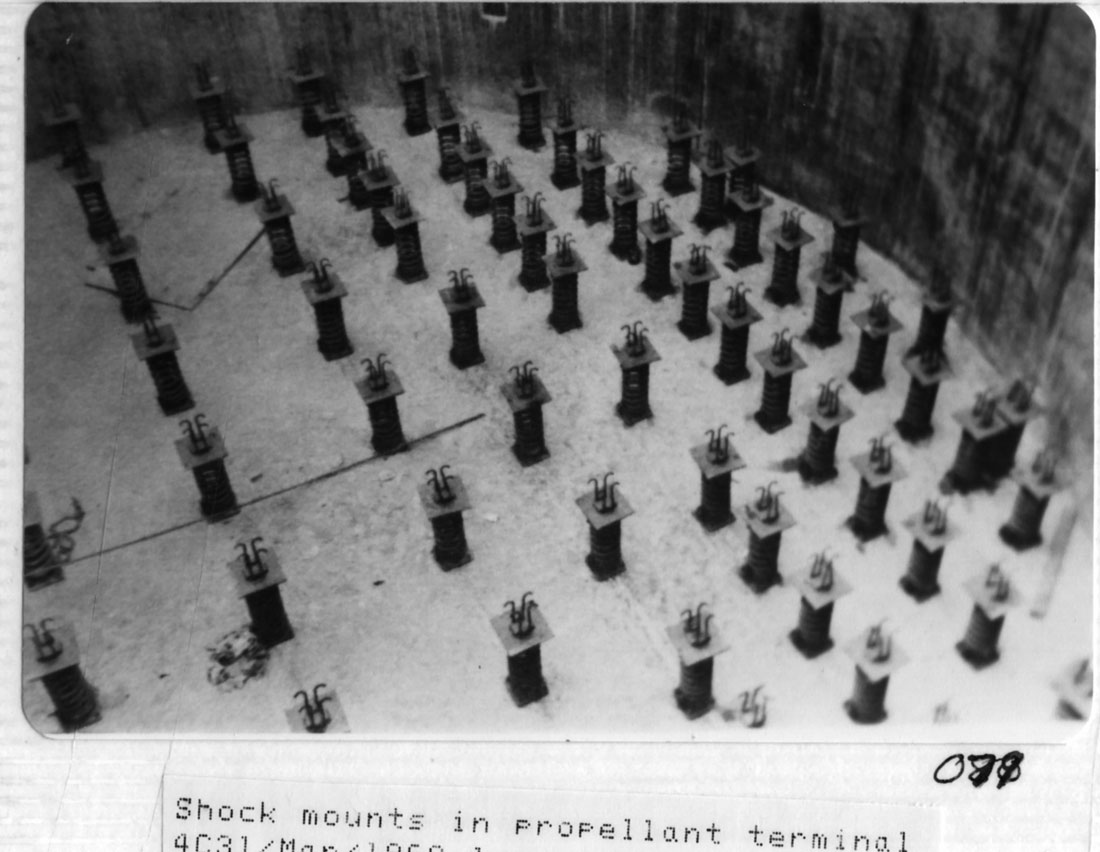

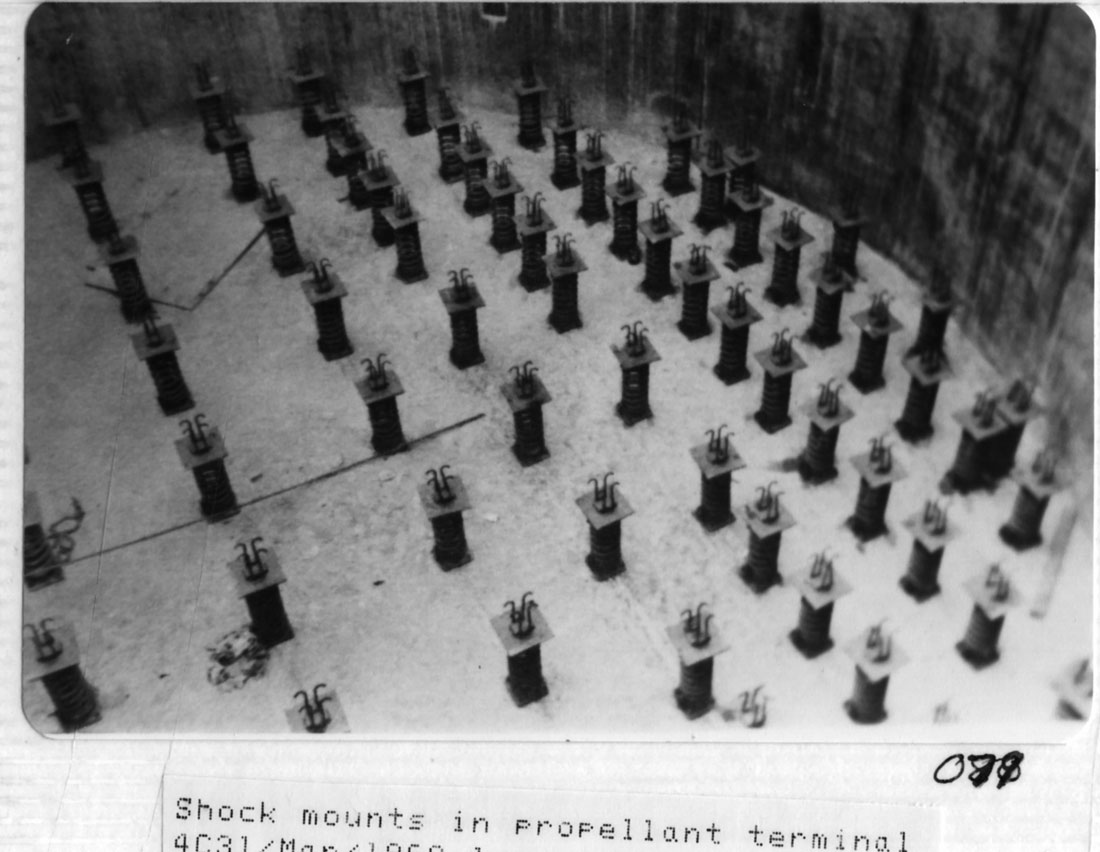

Spring

suspension mounts to support the propellant terminal floors.

Everything had to be able to withstand shock or a disastrous failure could

occur. The entire two-story structure was "floated" on

these springs.

Photo

courtesy of Fred Epler

|

It

was paramount that the propellant systems not be damaged both to

ensure launch capability and to avoid catastrophic fires and

explosions that could render the entire complex unusable.

There

was no greater threat to alert status and crew life and limb than the

propellants that drove the rocket motors. Even the warheads were a

far lesser hazard-- they were so sufficiently safeguarded that an

accidental detonation was unlikely even if the missile itself

exploded.

Fun

Facts About Modern Rocket Propellants

I

find it interesting that the

Titan II, which replaced the Titan I and all the existing Atlas

configurations at the time, was actually far more hazardous in terms

of the propellants used. Aerozine 50 and (50% unsymmetrical

dimethylhydrazine and 50% hydrazine) and nitrogen tetroxide are

hypergolic propellants, which means that they spontaneously

ignite when mixed. This is great inside of a rocket motor-- not

so great pretty much everywhere else.

Both

nitrogen tetroxide and the components of Aerozine 50 are highly

bio-hazardous and toxic:

Unsymmetrical

dimethylhydrazine (UDMH, C2H8N2):

-

Highly

flammable and highly explosive

-

Highly

corrosive

-

Forms

other toxic compounds when burned

-

Evaporates

easily at room temperature

-

Easily

absorbed through skin, eyes and lungs

-

Attacks

the central nervous system, liver and lungs

-

Causes

respiratory failure, liver impairment and death

-

Carcinogenic

-

Hazardous

to the environment

Hydrazine

(N2H4):

-

Highly

explosive and flammable

-

Reactive

with moisture

-

Forms

other toxic compounds when it breaks down

-

Can

be fatal with severe exposure

-

Highly

irritating if inhaled

-

Can

be absorbed through skin

-

Corrosive

to skin

-

Carcinogenic

-

Attacks

the blood, kidneys, lungs, mucus membranes and central nervous

system

-

Damages

organs with repeated exposure

Dinitrogen

Tetroxide (N2O4):

-

May

spontaneously ignite combustible materials

-

Reacts

with water to form corrosive acids

-

Reacts

with metals in the presence of water to form highly flammable

hydrogen gas

-

Highly

toxic if inhaled

-

Corrosive

to skin, eyes and respiratory tract

-

Can

cause fatal pulmonary edema

-

Accelerates

combustion

-

Hazardous

to the environment

These

propellants are still in use in one form or another today in both

domestic and foreign liquid-fueled rocket engines despite the

challenges presented by their use, storage and transport. The

most likely reason for this is the elimination of an ignition system

given their hypergolic property-- removing one more point of failure

in an extremely complex and expensive system.

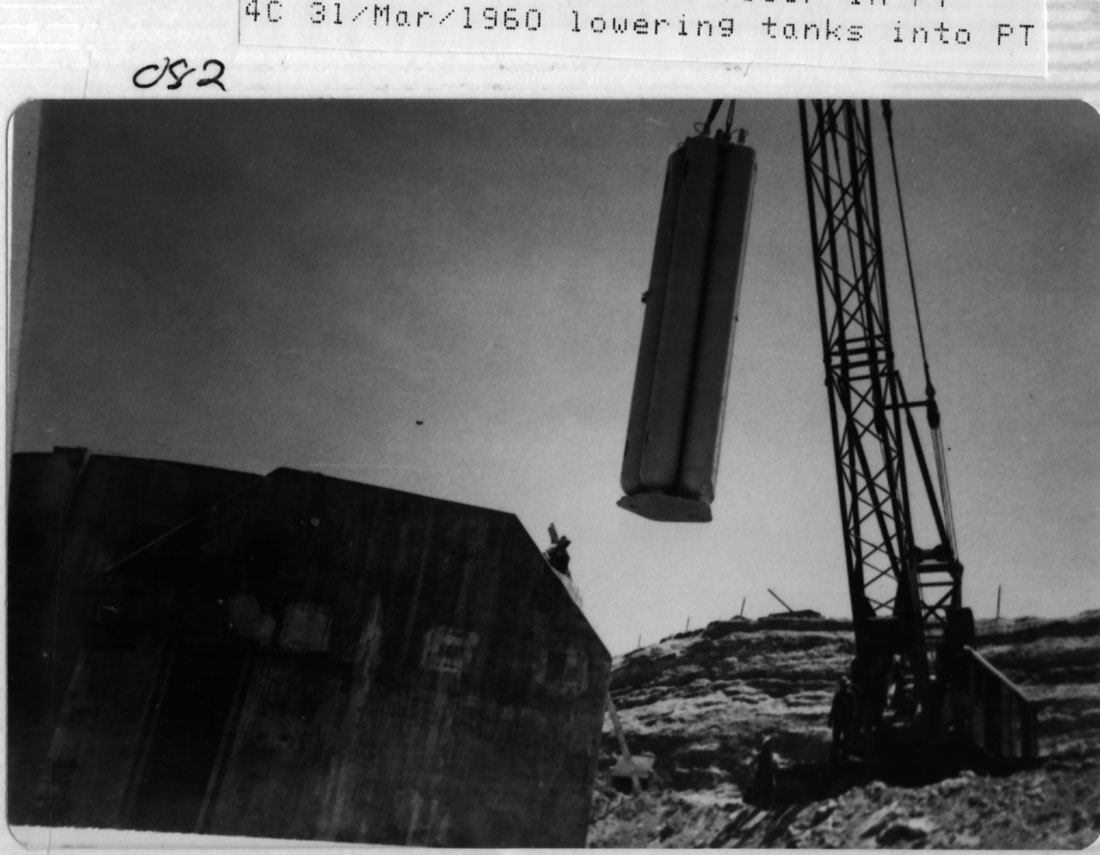

|

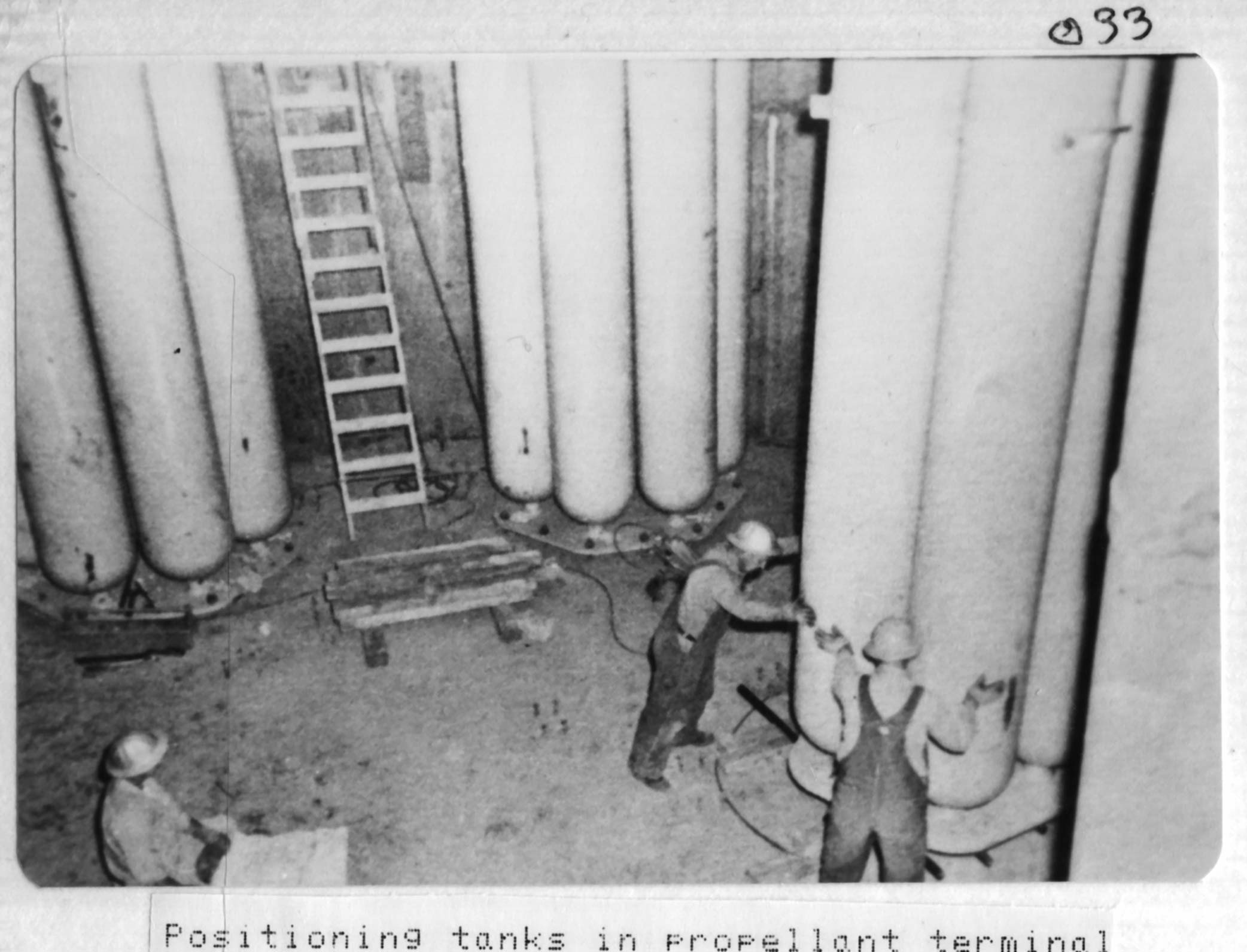

Installation

of the gas cylinders into the propellant terminals through the roof

access Photo

courtesy of Fred Epler

|

|

One

cluster at a time, each set of tanks was carefully emplaced Photo

courtesy of Fred Epler

|

|

Groups

of tanks being positioned and bolted in place Photo

courtesy of Fred Epler

|

Cryogenic

Gasses and You

Liquid

oxygen and liquid nitrogen are "cryogenic gasses", which are

gasses which have been chilled to the point where they change to a

liquid state. For liquid oxygen, O2

is chilled and maintained at around -170 degrees Celsius or -274

F. It probably does not need to be said (but here I go anyway)

that anything which is -100 Celsius or colder is likely to be quite dangerous.

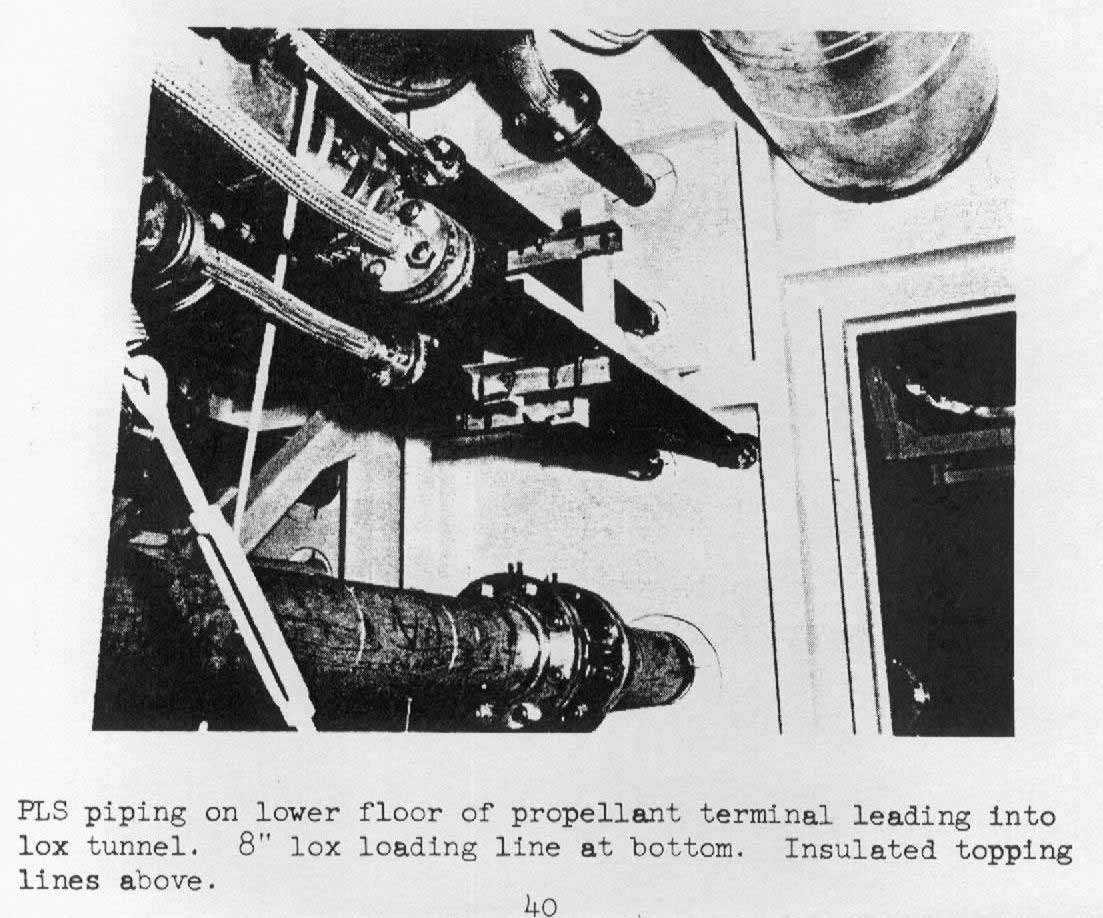

As

it was with the rest of the Titan I complex, all the piping in this

area was

allowed a certain degree of movement through the use of flexible

connections and gimbaled joints to help prevent ruptures to the very

complicated plumbing in this area. Because LOX is a concentrated

oxidizer, the piping and fittings were all stainless steel or other

non-reactive metals and were cleaned to stringent standards. Any

particulate, especially oil or grease in a LOX line can produce an

explosion.

|

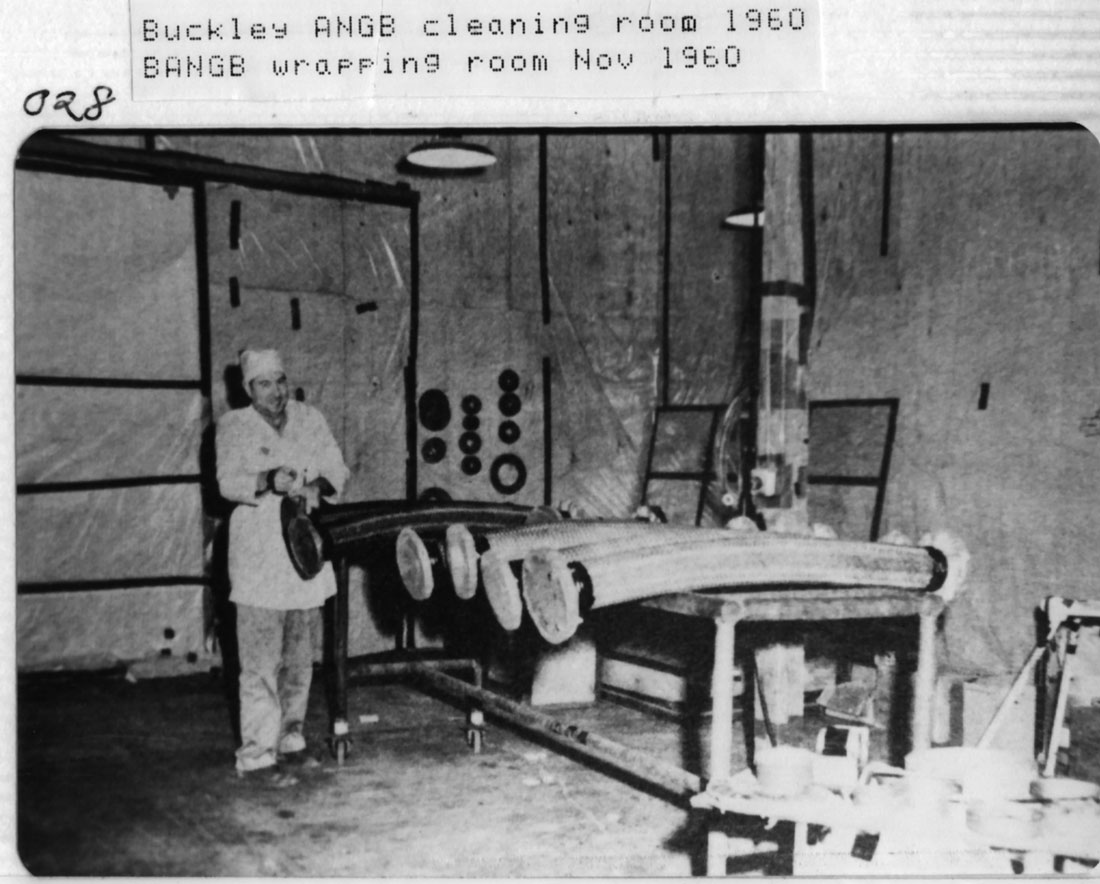

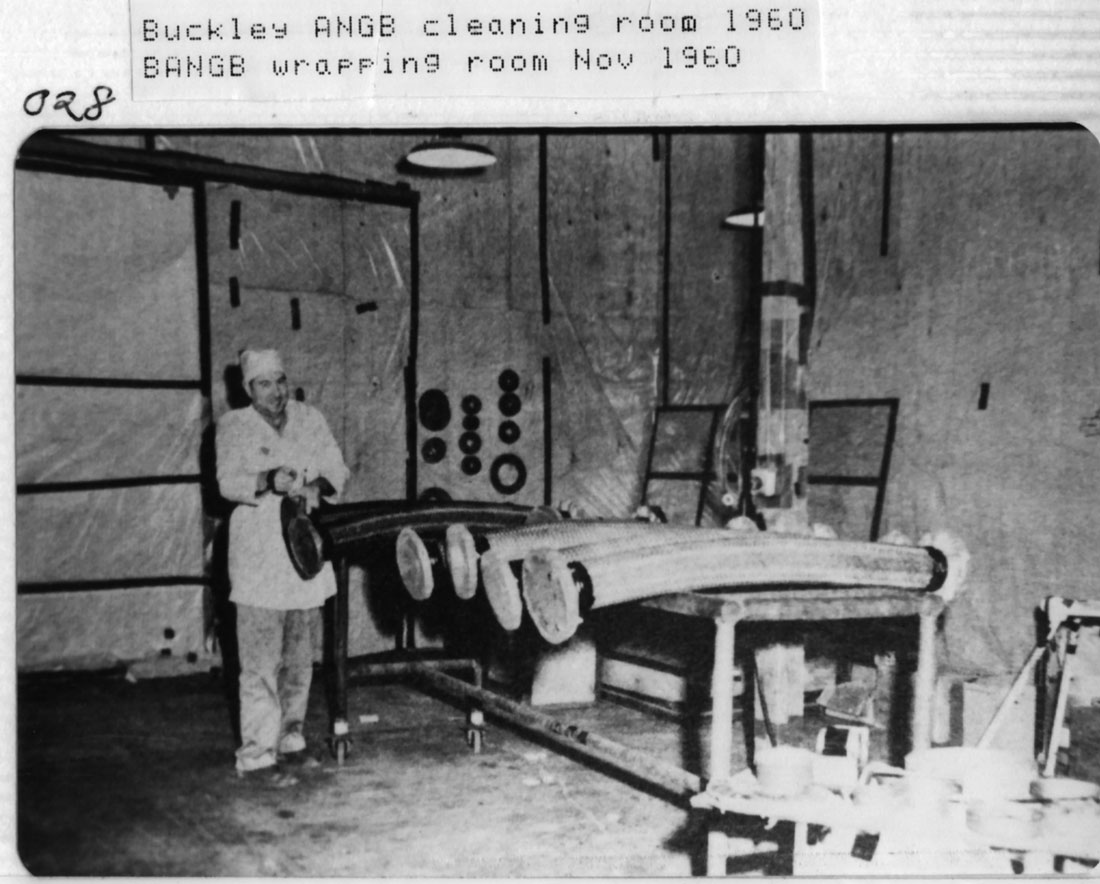

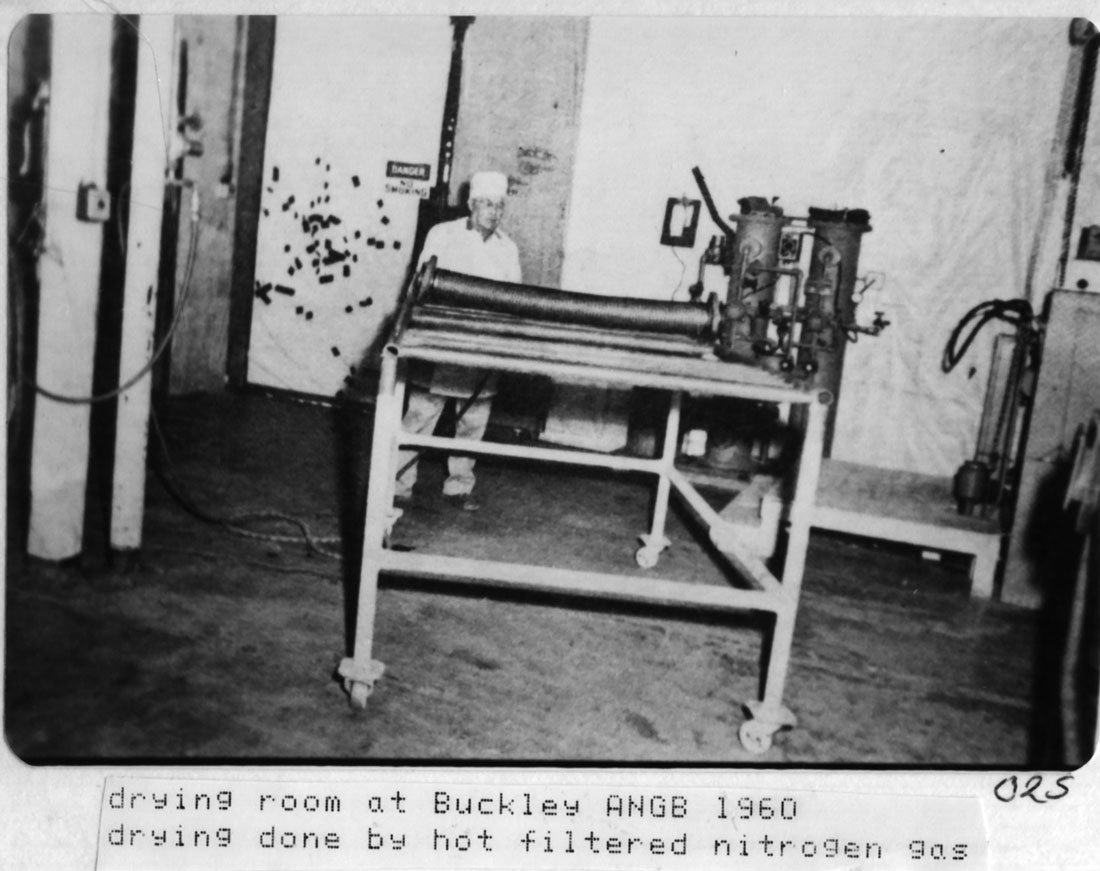

A

makeshift

clean room at the nearby Buckley Air National Guard base for

cleaning and drying components of the Propellant Loading System.

All conduit, valves and connectors had to be meticulously cleaned and

dried using nitrogen gas and then wrapped to keep out contaminants prior

to shipment and installation on site.

Photo

courtesy of Fred Epler

|

|

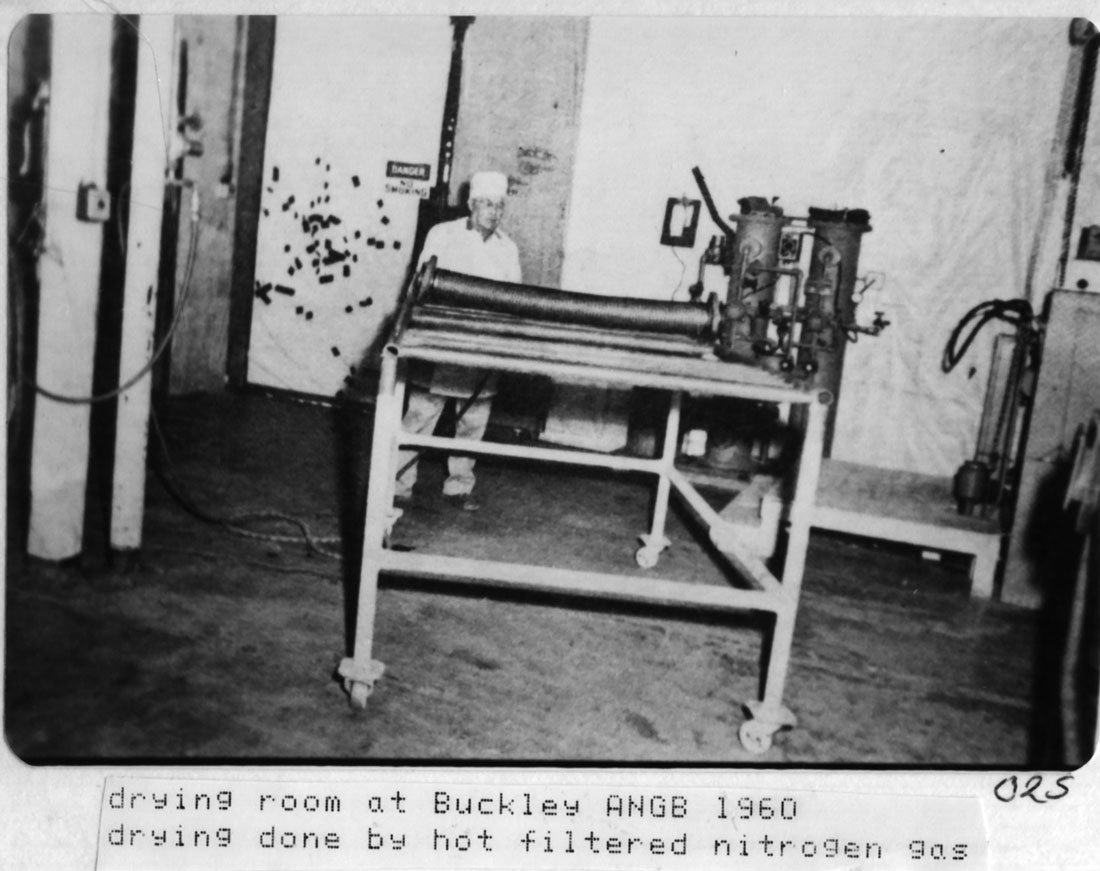

Drying

room with twin-column dryer at right rear. I regret I do not know

the names of the men in these pictures (and many others throughout this

website) so I cannot credit them for their

contribution to these early days of US missile defense. If anyone

knows who they are, please contact me.

Photo

courtesy of Fred Epler

|

Smoking

was an obvious no-no in the propellant terminal, but the liquid oxygen

presented other hazards beyond violent oxidation, presenting a

veritable cornucopia of potential dangers. Chief among these

dangers is the presence of oil or grease-- or any hydrocarbon that

could spontaneously create a fire or explosion. Hands, clothing,

tools and anything else entering the propellant terminal had to be

clean, static resistant and not emit any possible sources of ignition.

Sparks

and open flame are of course not safe near LOX and dropping tools is

also discouraged as it may produce a spark or if dropped on spilled

LOX could also result in an explosion. Special bronze tools are

commonly employed in such environments for the simple reason that they

will not produce a spark when dropped or striking another surface.

Appropriate

gloves, boots and aprons (to protect against spillage) were part of

the necessary gear for handling LOX. Aprons were mostly for fill

and drain operations, but leaks were always a concern. Because

of the enormous difference in temperature of piping and connectors and

the ambient temperatures when cryogenic liquids are channeled through them,

seals, bolts and connections expand or contract unevenly, pretty much

guaranteeing leaks during a transfer. For this very reason, a

catch basin was located below the steel floor grating to collect

spillage. An emergency eyewash

station and shower was provided on both levels of the propellant

terminals in case of accidental contact.

|

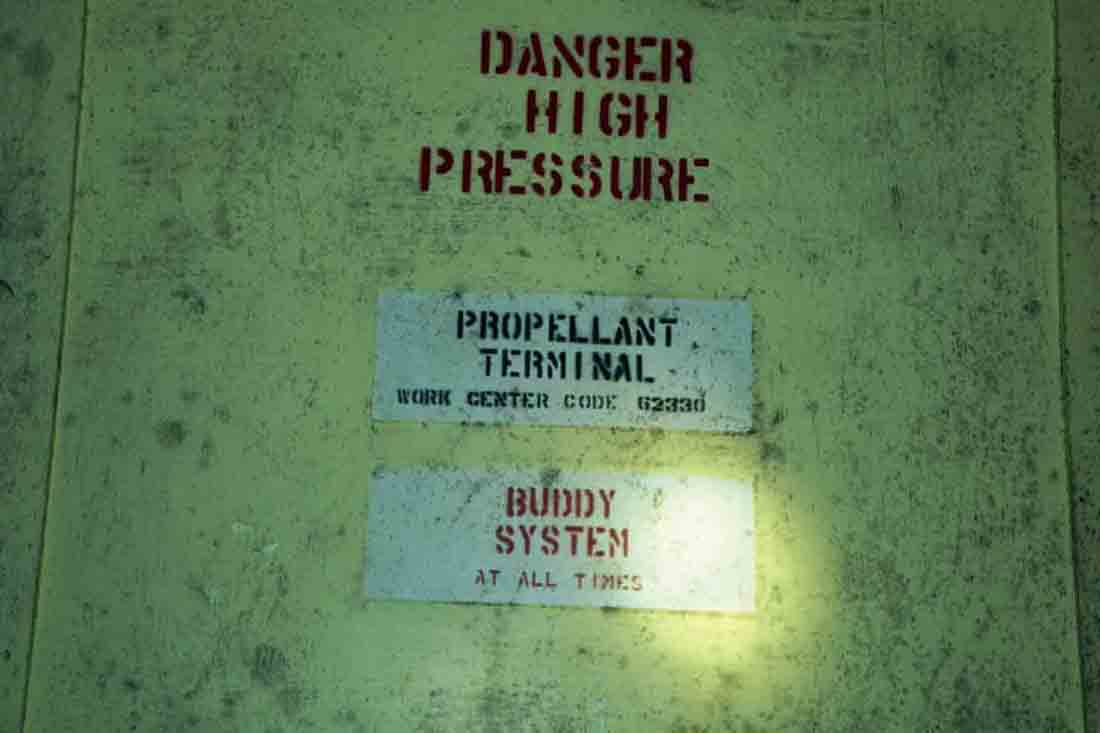

Operational

photo of the entrance to one of the three propellant terminals

|

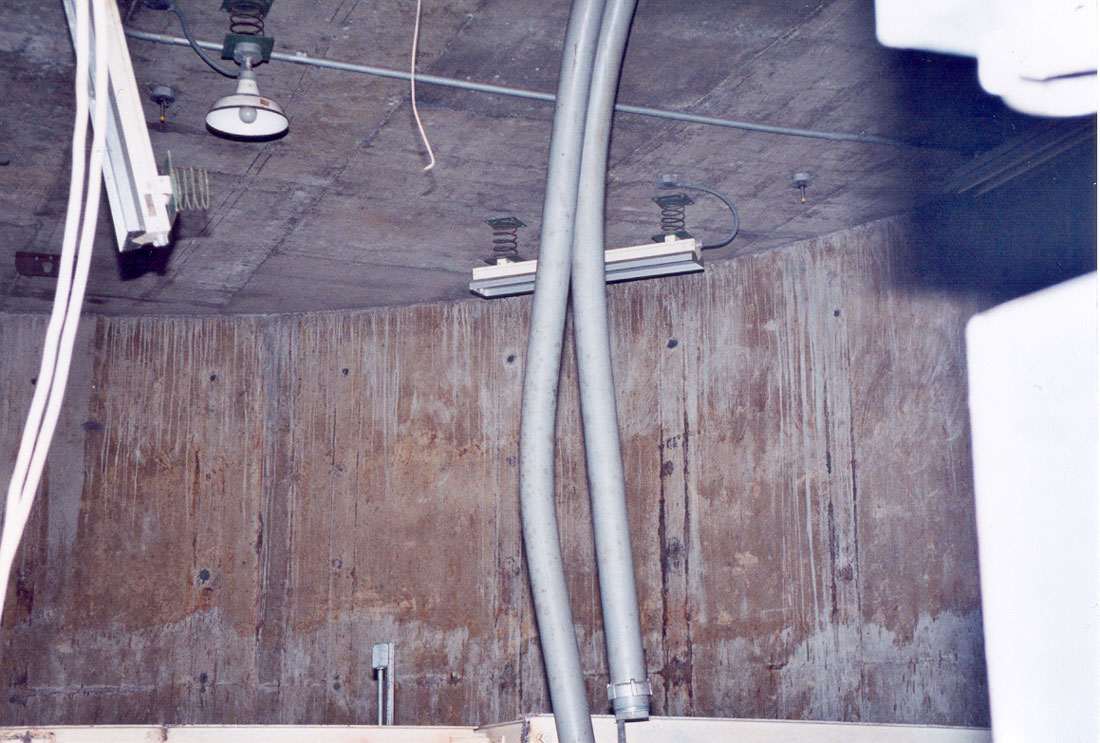

I

wish I had gotten more photos of this area, and even more so I wish I

had climbed up the remaining structure for some better shots. The

water you see here is over 2 feet deep and I guess I didn't feel like

dropping my camera in it when I passed through here.

The

entrance to the LOX tunnel is at the upper right in the above

photo. I did finally venture there to get some pictures which you

can see in the LOX tunnel section of the site (once it is complete,

sorry it is not up yet).

|

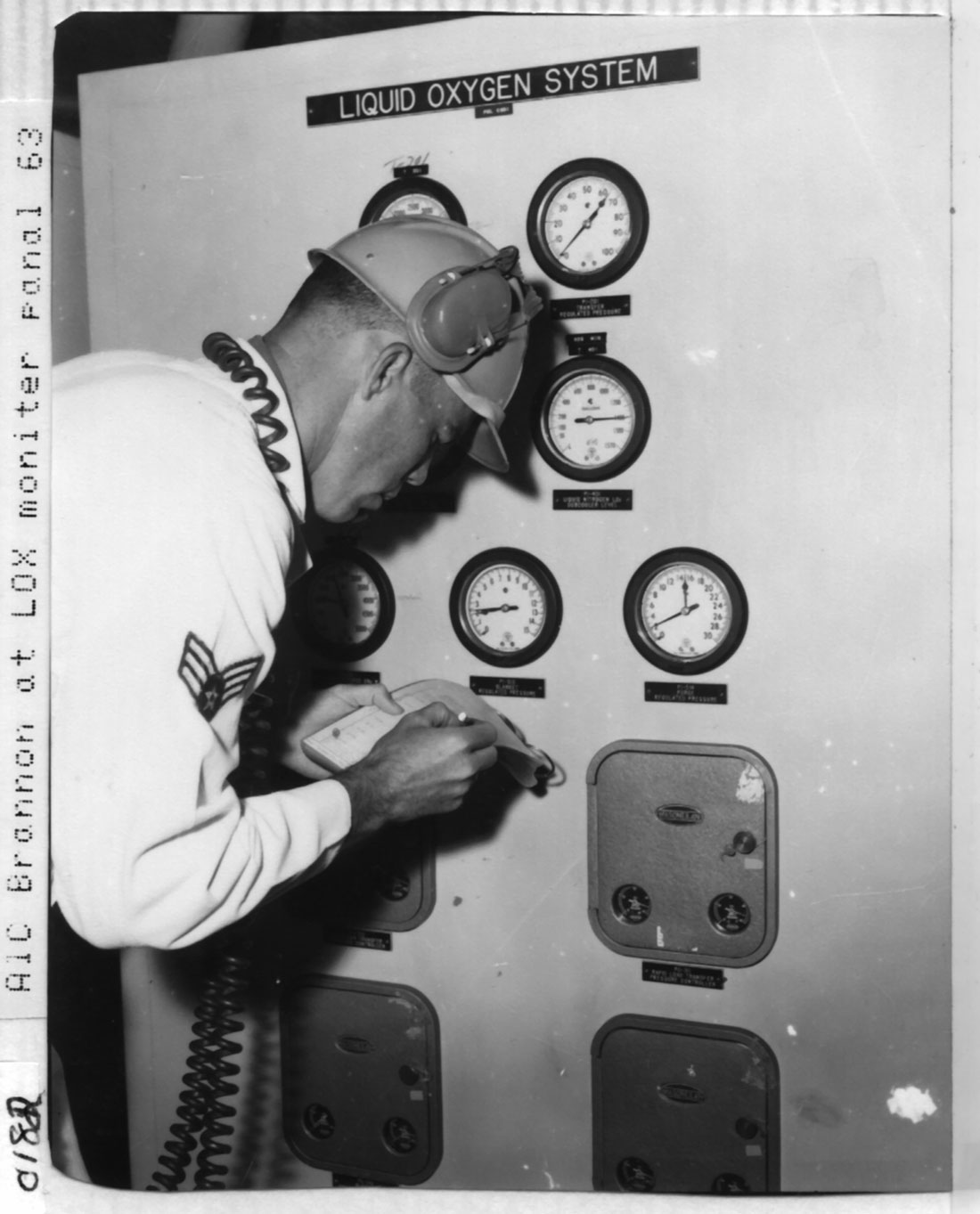

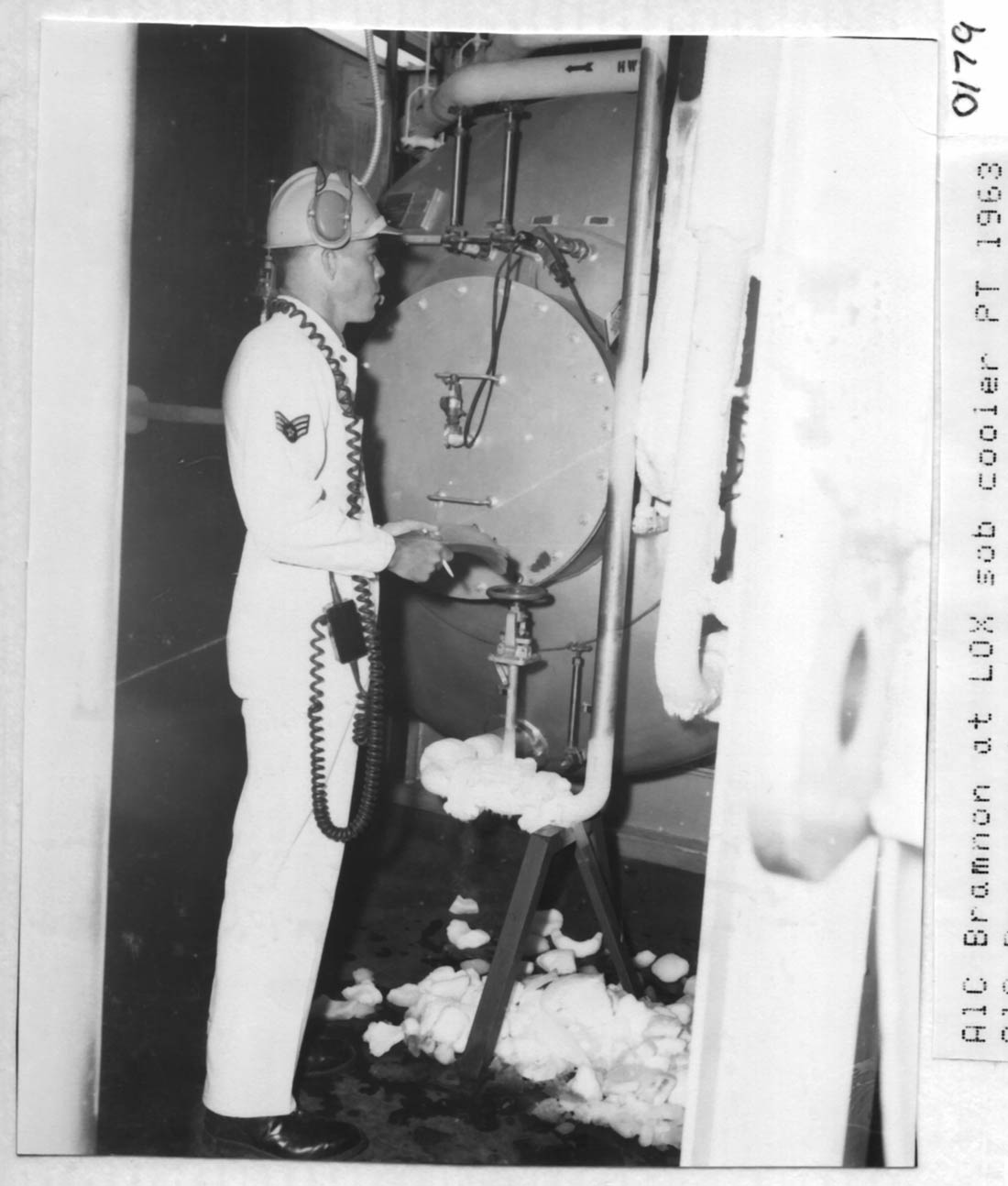

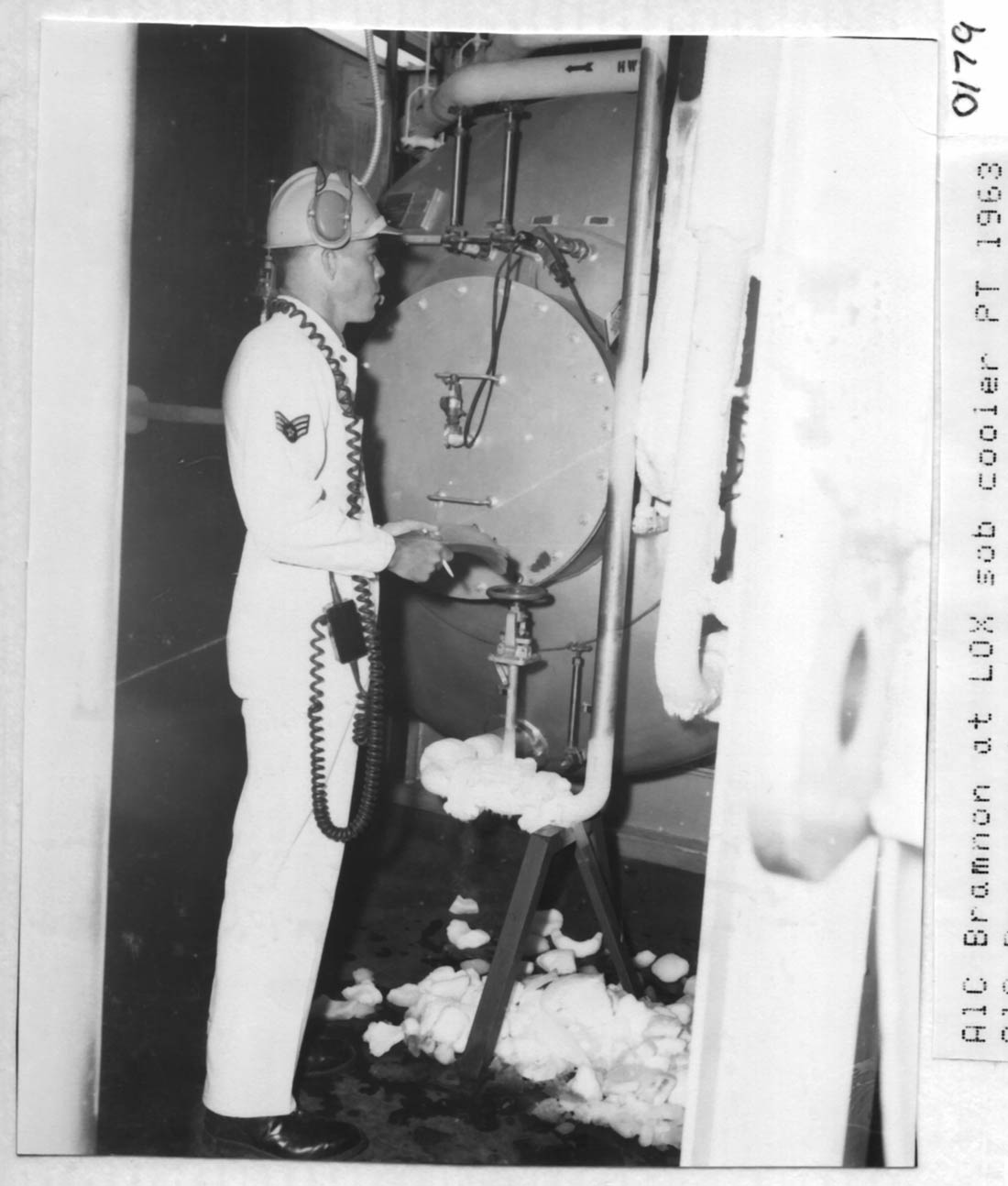

A1C

Brannon continuing his maintenance checklist on the lower level.

This is the LOX sub-cooler he's standing near-- it helped maintain the

-274F temperature needed to keep the liquid oxygen from becoming gaseous

again.

Note

the accumulated frost from the piping to the tank. You just know

some airmen were throwing snowballs around these sites!

Photo

courtesy of Fred Epler

|

|

Another

shot of the LOX sub-cooler and A1C Brannon

Photo

courtesy of Fred Epler

|

|

This

is how the lower level of P.T.#1 at 724C looks today-- rusty water and

steel scrap

|

|

Entrance

to the LOX tunnel during operation

|

|

The

entrance to the LOX tunnel today. The wall has been removed along

with the door. You can see a small ventilation blower

half-submerged at center. Ventilation was very important to keep

gasses from accumulating to the point where they could become an

explosion hazard or to the degree that they would displace breathable

air in the terminal. This area maintained a positive pressure to

force air to the surface via the LOX loading and vent shaft that

branched off of the LOX tunnel.

|

From

here you can move on to the LOX Tunnel,

go to the Main Map, or select a destination below:

Current

Location: Propellant Terminals

|

Where

would you like to go next?

|

| Contact

|

Site Map | Links

|

Hosted by

InfoBunker