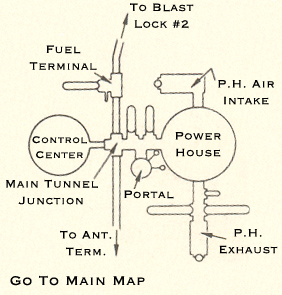

Power

House Air Exhaust

This

area is pretty self-explanatory for the most part and as expected was

largely built around the discharge of diesel exhaust from the

generators. There were other effluvia discharged here such as

waste heat, steam, and corrosive, volatile and toxic fumes associated

with various processes and the operation of the machinery in the Power

House. In short, this structure served as a giant tailpipe.

|

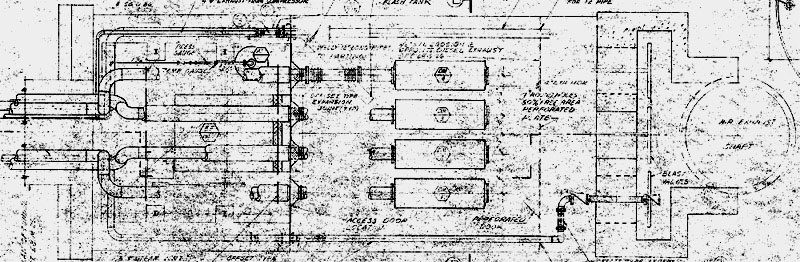

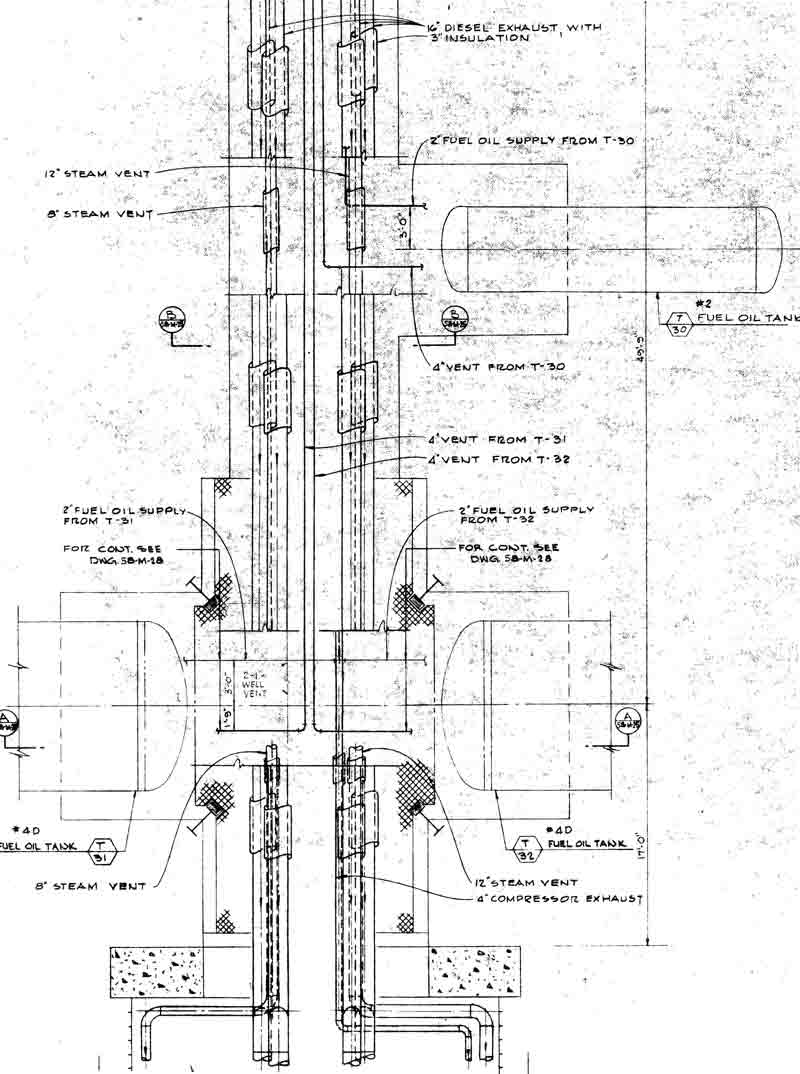

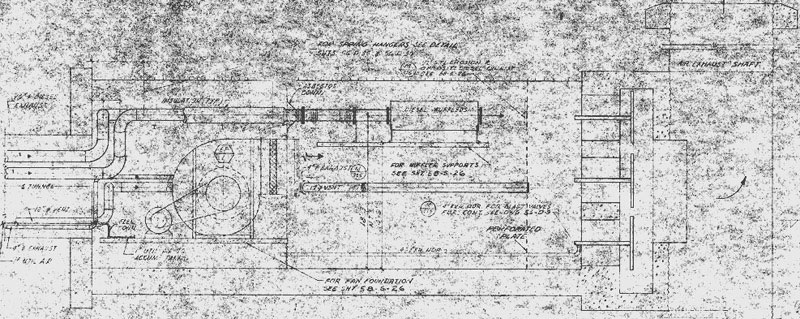

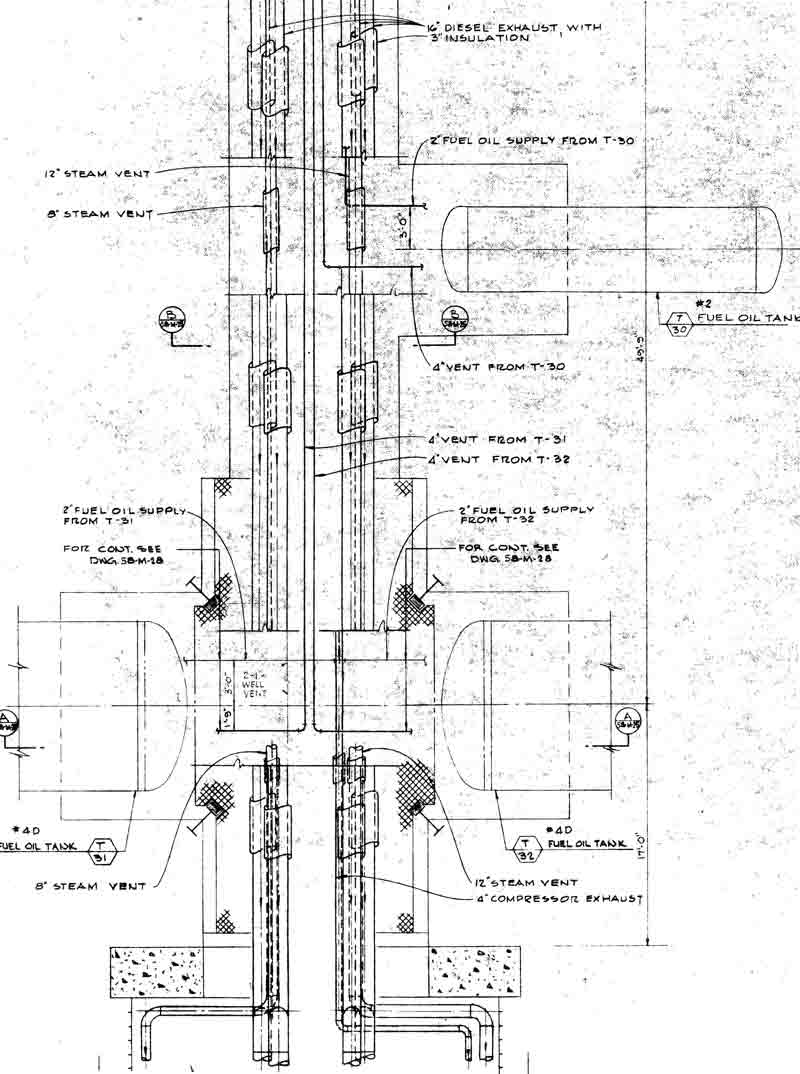

A

terrible-quality* top view diagram of the end of the exhaust tunnel showing the

four huge mufflers and the exhaust stack.

|

Though

in later revisions, the air intake and exhaust structures at other sites

would be radically redesigned, becoming much smaller and more cost

effective to construct and maintain, they were still impressive in

size. As they evolved from the much larger horizontally-oriented

configuration you see here, to the vertically-oriented and more compact

arrangement, they would be more effectively measured in feet than yards.

*

My apologies

about the blueprints in this section. The images were scanned from

nth-generation blueprint reproductions from copies made using the

standard diazotype method for copying blueprints. Later

generations using this method can tend to become very "muddy"

and end up looking dirty, smudged and damn hard to make out. I did

what I could to clean them up, but I am sad to say, this is the best I

could do.

|

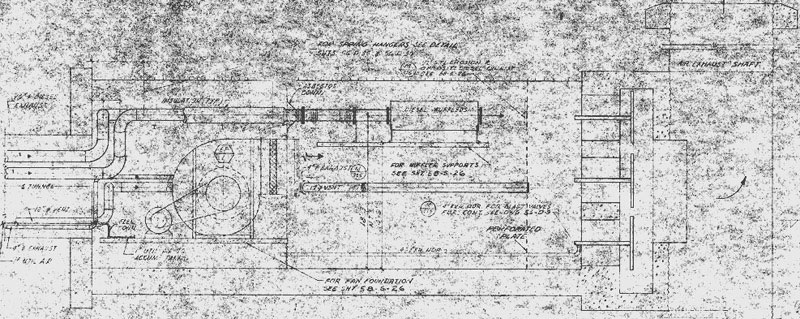

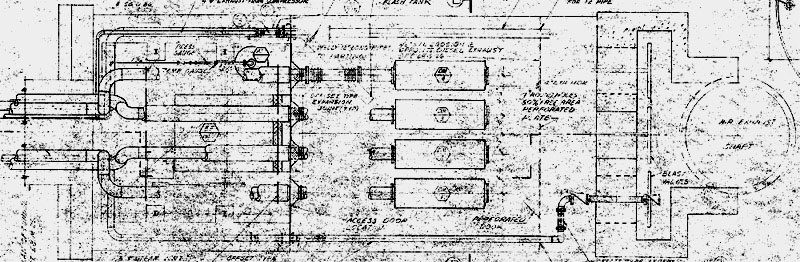

A

terrible-quality side view of the end of the exhaust tunnel showing the

fan, blast valves and upper level where the mufflers are located.

|

Not

including the connecting access tunnels, the air intake and exhaust

structures were large enough to accommodate a semi tractor/trailer,

whereas the later structures were roughly 40 feet in diameter. No

matter which, the function was fairly simple, and that was to channel

all undesired exhausts, whether from combustion or otherwise, to a

central location and eject them to the surface where they would be borne

away from the complex by the winds.

|

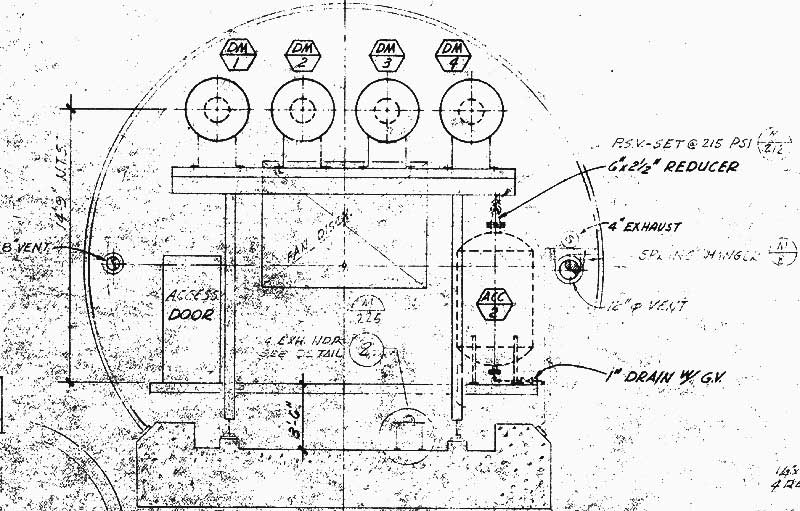

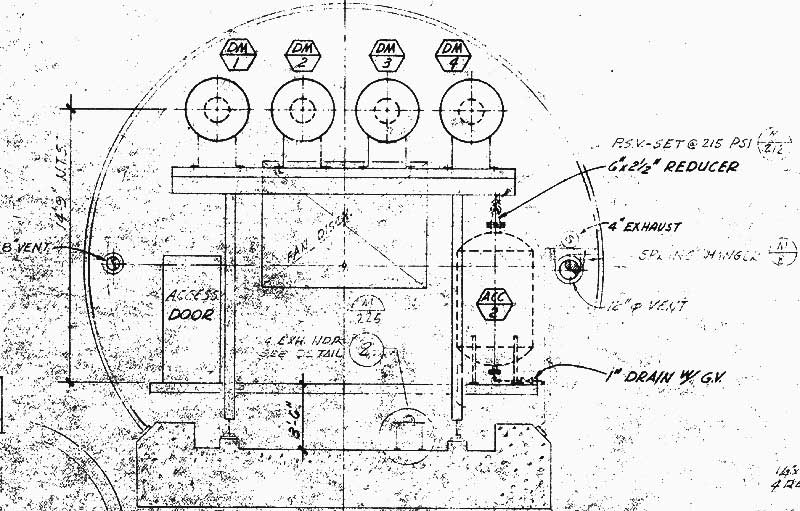

Cross-section

of exhaust tunnel at the mufflers

|

An

access tunnel (shown below) branched off of the mezzanine level leads

past the imposing diesel storage tanks to the exhaust fan. At that

point, the barrier between "inside" and "outside" diminishes

to one steel bulkhead while the complex is in a "soft"

state. Soft meaning that the blast valves are open and the site is

technically vulnerable to overpressures from atomic blasts as it takes

in air and expels exhaust.

|

Above

view of exhaust tunnel section adjoining the Power House mezzanine

level. Here you can see the location of the 5000-gallon diesel day

tank, and the two 67,000-gallon main diesel storage tanks. Just

past the bottom of this diagram, the tunnel widened where the 175,000

cfm fan was situated.

|

The

blast valves waited for any sign of a nearby blast that would trigger

them to slam shut in a fraction of a second, protecting the interior

from the shockwave. After the destructive forces had passed over,

the blast valves would re-open allowing the complex to breathe and

operate. The grim reality of fallout was that once the blast

valves opened again, contaminated air would be drawn into the complex.

|

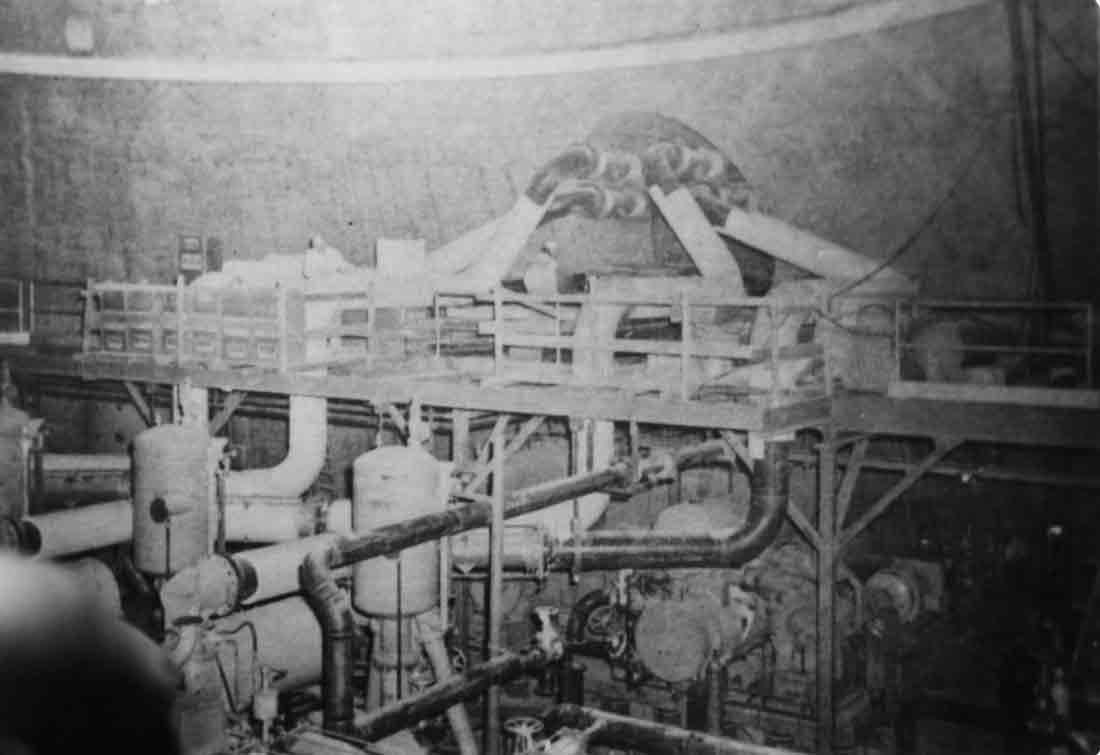

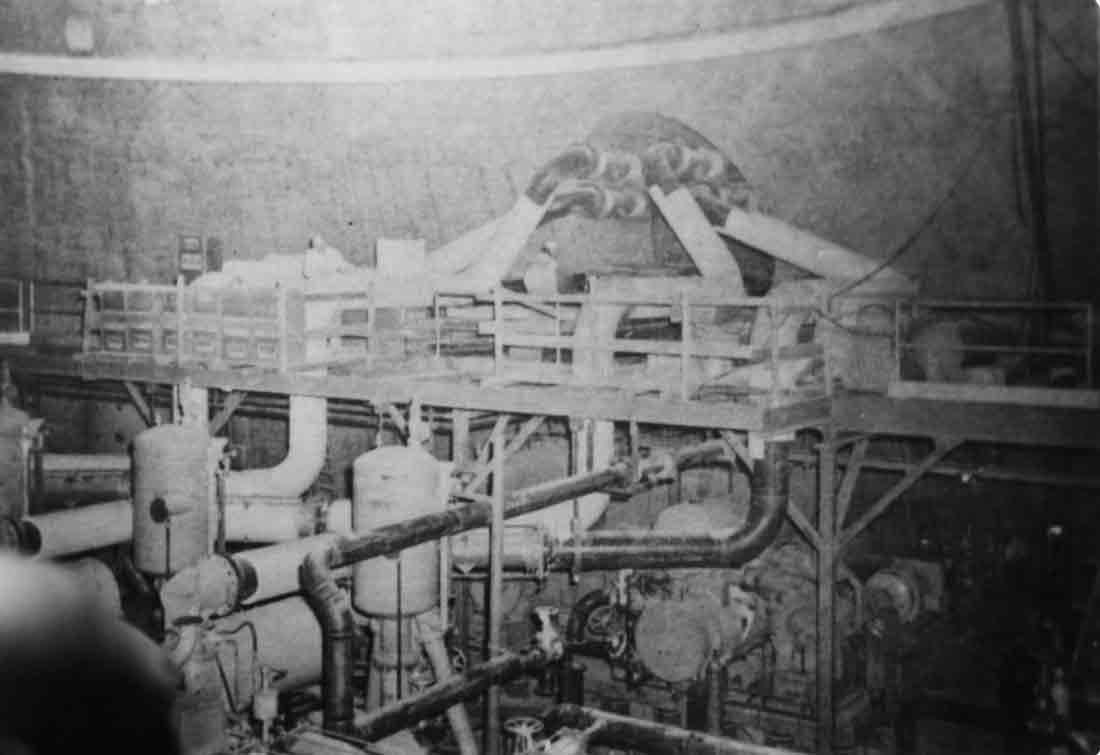

This

construction photo is the best source I have for a near-operational

image of the entrance to the exhaust tunnel. You can see here that

the 3" insulating layer of asbestos plaster is still in the process

of installation on the four huge 18" dia. exhaust conduits from the

generators. I have yet to come across operational photos of the

exhaust tunnel unfortunately.

|

|

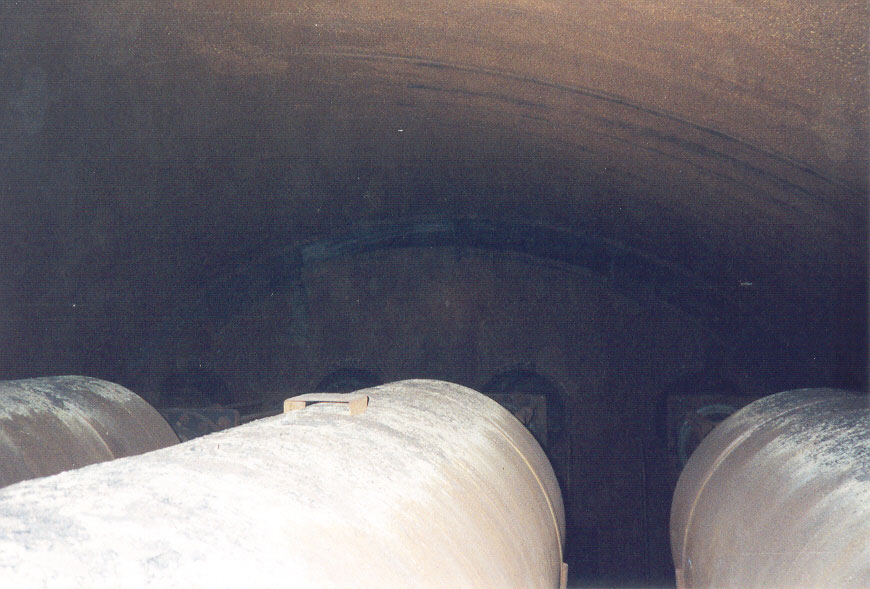

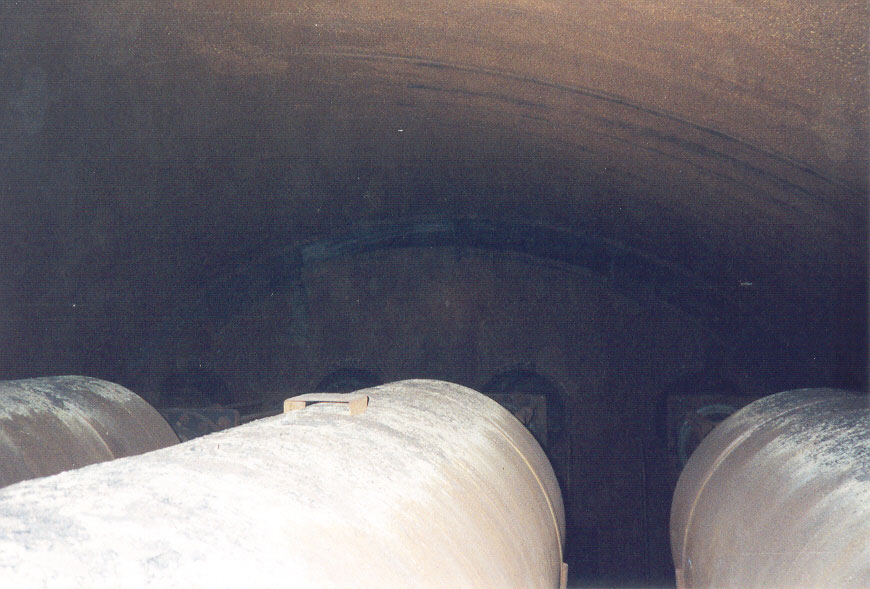

Here

is the present-day appearance of the same entrance shown in the previous

photo. The steel exhaust conduits have been recklessly stripped of

their insulation and cut free from their supports with torches and

removed. The asbestos plaster was left to lay where it fell and

ground into powder underfoot leaving eerie white residue, sometimes

several inches thick, covering the floor.

|

Some Words on

Asbestos Undisturbed

asbestos insulation under a good layer of paint or sealer is virtually

harmless if left alone. The trouble comes from damage to the paint

or the insulation itself that allows dust particles containing asbestos

to become airborne. Crushing this plaster into fine powder even in

small amounts is enough to close a public building for weeks while

cleanup is conducted.

Because of the onerous costs of abating asbestos from public buildings, most

buildings where asbestos was widely installed have instead had the

asbestos "stabilized" in one way or another. This

constitutes sealing over insulation or material that contains asbestos

so that it cannot easily be disturbed and thereby become friable (easily

crumbled) and prone to become airborne where it can be inhaled.

Obviously this was never done in the 1960's so this area of the complex

represents a "worst case scenario" of asbestos in its most

disturbed state and in exposure to unprotected visitors.

While

it is widely held that the dangers posed by asbestos are largely

overstated (please note, this is not my personal position on the matter,

and I will not substantiate on this further. Take that as you

will.), it would be wise to err on the side of caution and avoid unnecessary

contact with a material known to cause cancer and several forms of

serious respiratory disorders that can shorten one's life

considerably. Personally, I would hesitate to say that the dangers

posed by asbestos are wildly overblown, but let's be frank, nothing

makes a lawyer smile like a class-action lawsuit, if you get my drift.

For

more general information on asbestos, check Wikipedia's entry here.

|

This

is the area of the complex that poses the most danger by

contaminants. The ratio of asbestos in plaster used for this

application would be the highest-- likely 20% or higher, and its

condition is about as bad as it can get. That ain't all-purpose

flour you see on the floor.

|

As

far as the function of this area, there is not much else to tell.

On inspection, I found it difficult not to worry about all the harmful

dust in this area, which nearly overshadowed the constant general danger

associated with being in such an environment. In time, I must

admit that I became more relaxed and perhaps a bit complacent about

roaming around inside the complex. This is a dangerous state of

affairs and is wisely discouraged.

Over

the two years I stood watch over 724-C, I had a few unusual requests

amid showings to potential buyers (no, I was not the owner, just

a caretaker of sorts). One person wanted to film a

post-apocalyptic sci-fi film in the complex, and another wanted to film

a small independent documentary. I am sad to say that these

requests were declined due to the ungodly liability involved in such

enterprises.

However,

to make my point about complacency in regards to safety, there was a

film crew down in the site after it was purchased. I was told that

MTV did a shoot about urban exploring and featured 1C in their

program. I don't know if this show ever aired, or was in fact just

a myth. (can anyone verify this?) At some point a producer

or director (I cannot recall which) is said to have become lapse in his

attention and stepped right off a gap in the flooring of one of the

tunnel junctions near the escape hatch and dunked himself completely in

the filthy water. I didn't hear of any injuries, but I can tell

you that I cringe to think of being submerged in that muck containing

the liquefied corpses of numerous small animals and lots of other

filth. Yuck!

|

Diesel

tank No. 3, or the 5000 gallon day tank, housed in an alcove off of the

exhaust tunnel. This tank has an outside diameter of 6' and is 24'

long. A day tank is typically a tank intended to house an average

day's usage of fuel. This tank was supplied by two much larger

tanks located further along the exhaust tunnel.

Resting

on the floor is enough asbestos to elicit screams of raw horror from any

facilities manager of a public or private building. Well in the

U.S. anyway... Lots of countries would simply pick it up and throw

it in the trash as its use is not banned in many places.

|

|

Further

along the tunnel there is a junction where the two 67,000-gallon diesel

tanks are located-- one on the right and another on the left. Dead

ahead you can see the gray enclosure for the fan and the stubs of the

exhaust conduits stabbing downward from the darkness above.

|

If the 5000-gallon day tank was

in fact an accurate measure of average daily fuel consumption, then with

full tanks the Titan complex could expect about 27.8 days worth of

run-time before requiring a refueling. I am fairly certain however, that

refueling was done more frequently than once a month.

As

you can see, there is a sub-floor here with the usual steel

decking. This floor continues up to the bulkhead near the fan.

|

Diesel

tank No.2 has a capacity of 67,000 gallons, has an outer diameter of 12'

and is 80' in length. The access hatch is about 18"

across. Ask yourself how well you could fit through there!

|

I am

not sure why the access hatches are open on the tanks. Perhaps the

fuel was siphoned out directly or a visual inspection was required to

verify the removal of the diesel.

|

Diesel

tank No.1, same as No.2-- 12'x80' and 67,000 gallons. Note the

section of steel railing propped against the tank. This

facilitated a peek inside which revealed standing liquid in the bottom

of the tank. Not sure if it was collected condensation or diesel

residue. Unlike tank No.3, tanks 1 and 2 said nothing about having

been cleaned, remediated or otherwise conditioned since the site's

closure*.

Oftentimes

these single-walled fuel tanks were first cleaned and then filled with

sand or concrete by (or on behalf of) the EPA to prevent their

re-use. Double-walled containers are the modern standard for

environmentally sound fuel storage, and single-walled tanks are no

longer legal for underground fuel storage. 725A and I believe 724A

have had the tanks "stabilized" in one of the above fashions.

*

As of 2003. I

am fairly certain this has not changed, but cannot verify this.

|

|

Another

view of tank No.2. One of the fuel supply lines to the day tank,

protrudes in the foreground. Fill connectors were located at the

surface near the entry portal.

|

|

Silo

Gnome looking for all the world like he's about to become the unwitting

comic victim of some devastating downpour of vile effluvia from above.

The

pipes are of course the remnants of the diesel exhaust conduits where at

this point two 90-degree offsets conduct the exhaust upwards toward four

gargantuan mufflers in the ceiling on the other side of the nearby

bulkhead. Here you can see where a generous amount of

high-asbestos-content plaster is still in place. Removal of the

piping was obviously too much trouble beyond this point to be bothered

with by the time-constrained salvage contractors.

|

|

The

Trane Co. squirrel-cage fan with exhaust lines running overhead.

You can see the steel bulkhead separating the raw exhaust discharge from

the interior of the complex behind the fan. Overhead the exhaust

lines pass through the bulkhead to the mufflers on an upper platform

which I'll show you shortly.

|

As

was the case elsewhere in the complex, the electric motor for the fan

had been salvaged. I later saw the sort of motor which was used

with these units and they are quite large and heavy as you would

expect. They are not really all that interesting however, but

typically they used 3-phase power and were usually made by GE.

Not

visible in the above photo is the narrow access door to the right side

of the fan that leads through the bulkhead.

|

A

view of steelwork and supports at the bulkhead. The fan in the

exhaust tunnel, like that of the intake is mounted on a

"floating" platform to arrest vibration both from and to the

fan and motor. The steel cable is part of the suspension

supporting the platform. Other smaller exhaust lines can be seen

at left, also shock mounted with springs and flexible couplings.

These lines often carried steam, or vapors from lubricants, diesel or

acids employed in the raw water treatment system.

|

|

Another

view of the bulkhead and supports. Arguably the most fascinating

photo so far, I know.

|

Heading

through the access door and taking a long step down (about 3') affords

you a view of the sooty tail-end of the exhaust tunnel. The

picture below shows the exhaust fan as seen from beneath the muffler

platform. This area was extremely dirty and badly rusted from its

proximity to the outside air.

|

The

outlet of the exhaust fan: it blows big-time! The ladder leads up

to the mufflers on an overhead platform. The impeller is

surprisingly small compared to the housing that contains it.

|

Heading

up the ladder, we see the colossal mufflers. Head room was a bit

sparse in places and the darkness swallowed up my puny camera flashes

voraciously. I did what I could, but I wish I could have had a

digital camera back then.

|

On

the upper platform: Flex connectors to the mufflers where they penetrate

the steel bulkhead.

|

|

The

absolute most massive mufflers I am likely ever to see! (or anyone else

for that matter) Everything in this area was covered in thick

black soot. I imagine this area was as black as coal during

operation. Only four decades of cold and humidity have made the

soot slowly exfoliate and account for it looking this clean here.

|

|

Looking

back toward the bulkhead and Power House. These mufflers are about

4' in diameter and around 15' in length. I bet you can't find

these at NAPA.

|

|

Looking

toward the blast valves. The accumulated soot is several inches

deep on the far ends. I strongly suspect no one ever ventured in

here while the generators were operating!

|

|

Large

flappers on the ends of the mufflers.

|

Below:

Another narrow access door leading to the blast valves.

|

Looking

toward the blast valves in the direction of airflow. Diesel

exhaust was drawn down from the mufflers above and out to the surface

through a steel grille. A steam vent protrudes into the image from

the left side.

|

For

anyone who might foolishly think of attempting to gain access to a Titan

site through the air intake or exhaust: let me tell you that you will

definitely not fit through the gap between the valve and the opening;

and if you could, its not likely you'd make it past the supports on the

actuator. Add to that the danger of descending (and later

ascending) some 50' by rope into a pit with water at the bottom and I

should hope you have ample deterrent from any such endeavors.

|

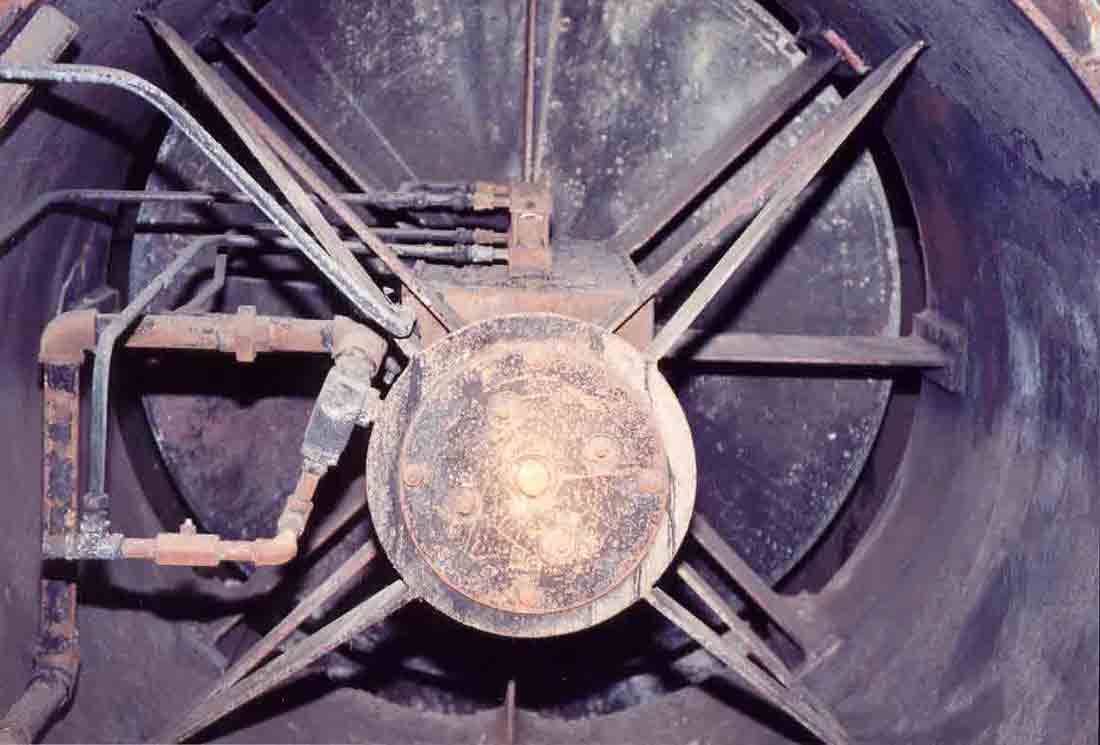

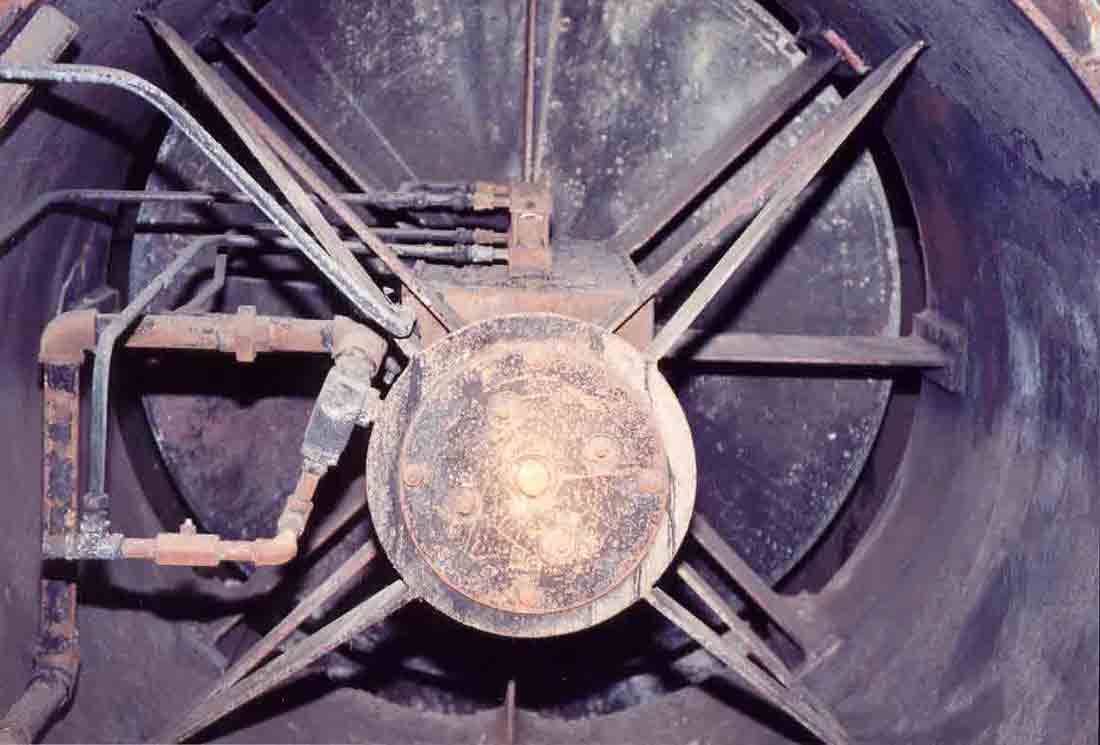

A

close-up of a soot-encrusted 48" blast valve.

|

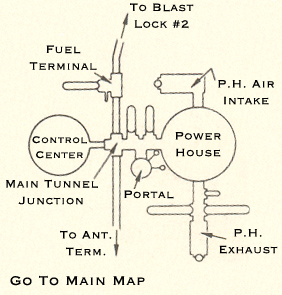

From

here you can head back to the Power House,

check out the Power House Intake,

return to the Main Tunnel Junction

(T.J.#10) or visit other points of interest using the map

below:

Current

Location: Power House Air Exhaust

|

Where

would you like to go next?

|

|

Contact

| Site Map | Links |

Hosted by

InfoBunker

|