The

Crib Structure Continued Yet Further

PLEASE

NOTE: Many images in this section are very high resolution

and may take a while to load. The images are much larger than

they are displayed here, so if you save and view them you can see

them at full resolution. Please be patient and enjoy the

details.

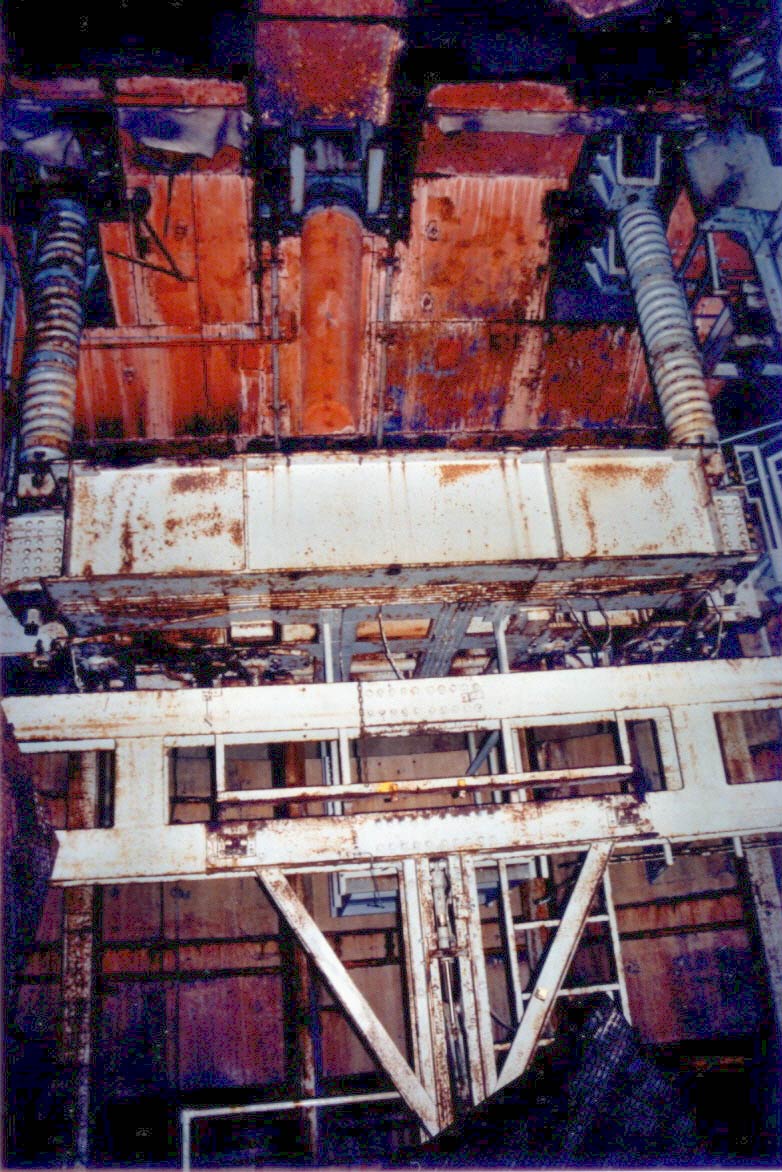

In

this section we descend even further along the cribwork's maintenance

levels and get a broader view of the cribwork from the silo cap

perspective as we approach the deepest accessible depths of the Titan

I complex. Sadly, since the silos are flooded to varying depths,

one cannot get a look at the very bottom of the silos-- or can

we?

|

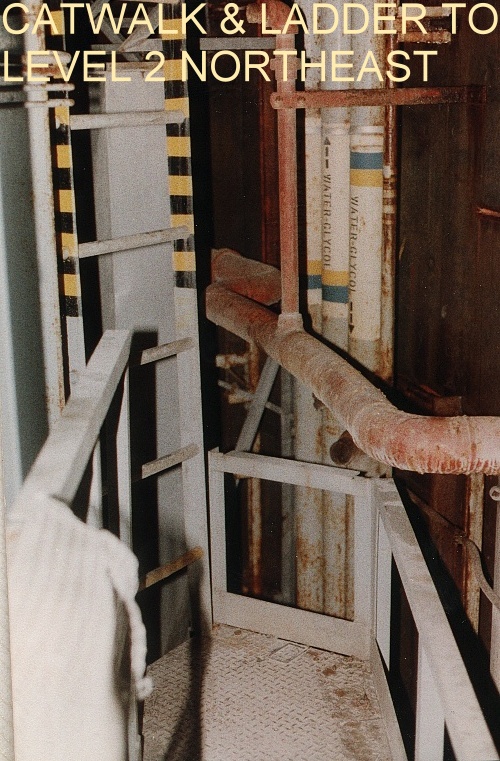

While

all the sites had personnel elevators to service the maintenance levels

in the silos, only the Vandenberg site had spiral stairways to move

between levels. If you worked at one of the operational sites and

the elevator was in use or not available, you had to schlep up and down

these ladders instead!

|

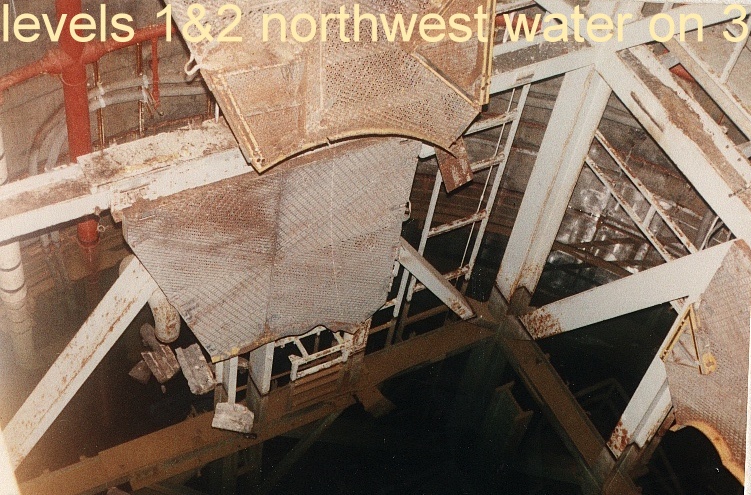

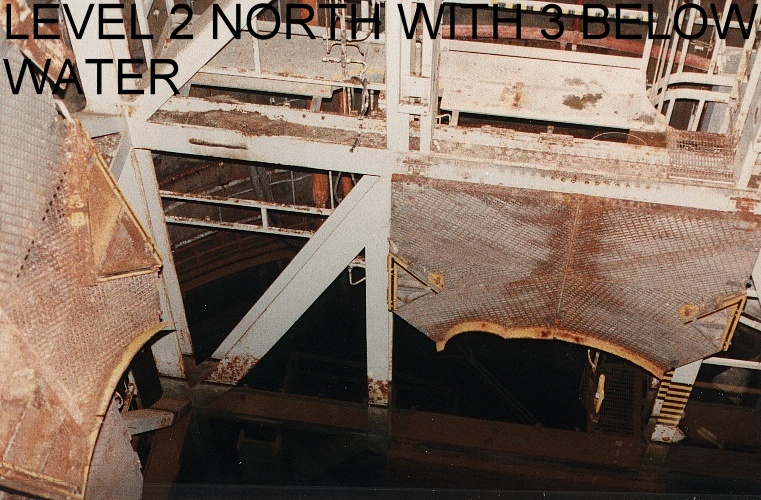

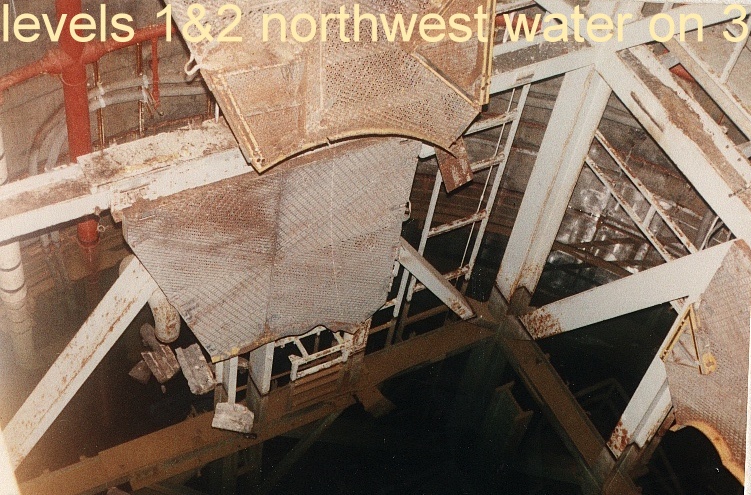

Descending to level 2 you

can see the extent to which this particular site was flooded.

Some fun facts to bring a bit of perspective here:

| Depth of the Titan I silos: |

150 feet |

| Diameter of silos: |

40 feet |

| Volume of empty silo: |

188,496 cubic feet (rounded to nearest unit) |

| Estimated depth of water in photo below: |

Approx. 80 feet |

| Volume of flood water in silo at 80 feet deep: |

752,024 gallons (rounded to nearest unit) |

| Weight of 1 gallon of fresh water: |

8.345 pounds |

| Approx.

weight of 80 feet of water in the silo: |

6,275,639

pounds or 3,137.82 tons |

| Time

to sump silo using 116 gal/minute pump:* |

Approx.

108 hours or 4.5 days |

*Assuming

a flood depth of 80 feet.

For

those out there who may already own a silo or those who would love

nothing more than to buy an old missile complex and clean it up and

restore or renovate it, this is a taste of what you might encounter

while working on a Cold War "fixer upper".

Dewatering

a silo would also require the use of an expensive commercial sump

system capable of lifting water from 150 feet down-- far more than

most pumps can handle. The breed of pump that can handle this

job is generally used for sumping out mines and construction

sites. While such a pump can certainly be sourced and purchased,

it would likely be best (and cheaper) to hire someone experienced to

handle the job.

I

don't want to sound like I'm trying to discourage anyone from trying

to fix up a site, far from it, just be prepared to run up against some

solid challenges when it comes to reclaiming some areas.

Heading

down toward level 2 things start to get a little more damp....

|

As

you can see here, there is not much further one can go before they hit

water

|

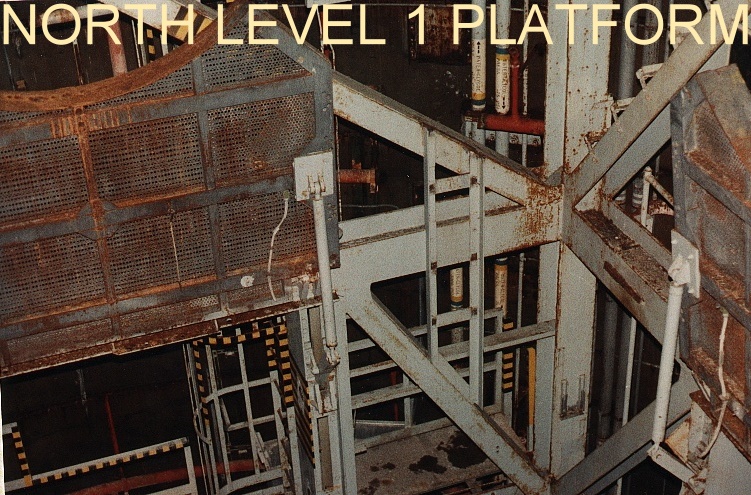

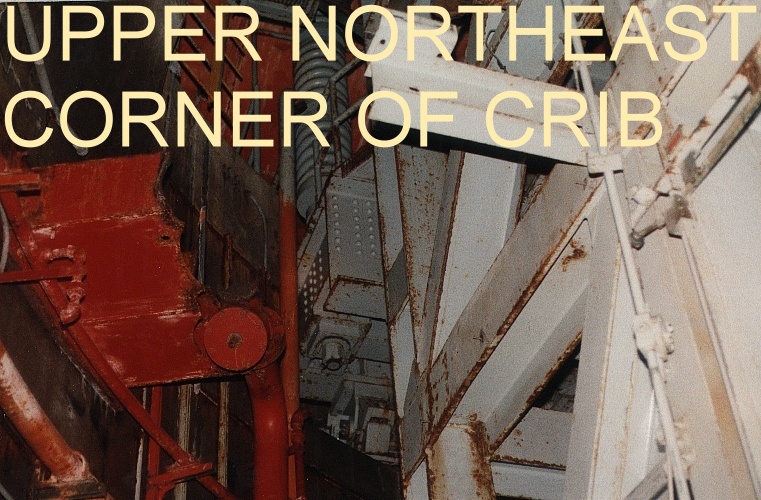

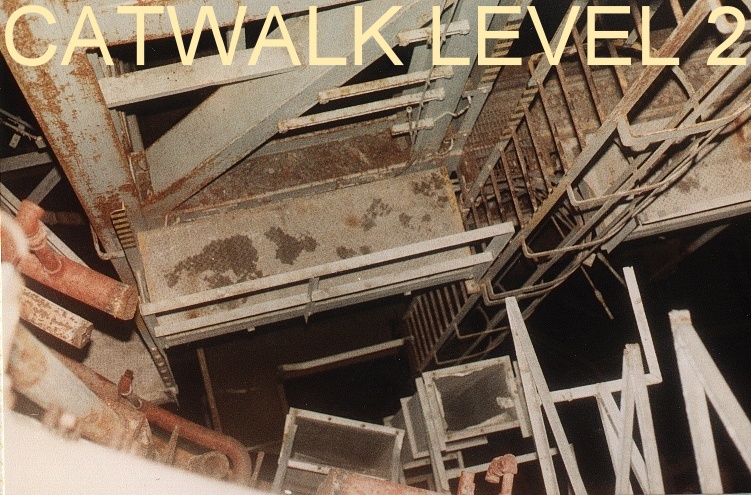

This

next group of photos give a good look at the outside faces of the crib

structure and some of the catwalks that run about on the levels still

above the water.

|

How

do you break something as stout as the counterweight rail? I

imagine a large, heavy object being lifted from the silo by a crane with

just enough freedom to swing into the rail as it passed. Quite

probably it was one of the counterweights themselves that inflicted that

damage I suspect.

|

|

The

floating debris is soggy fiberglass pipe insulation

|

|

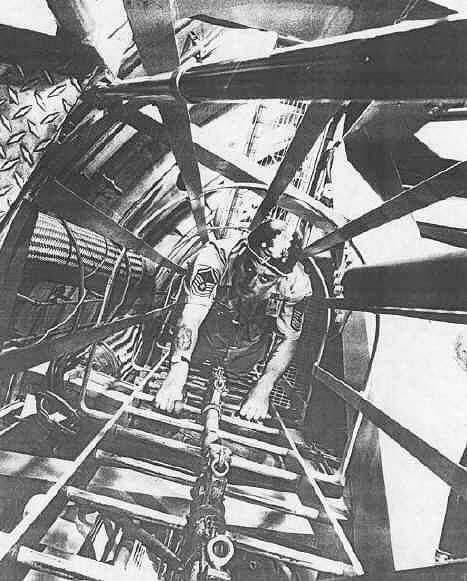

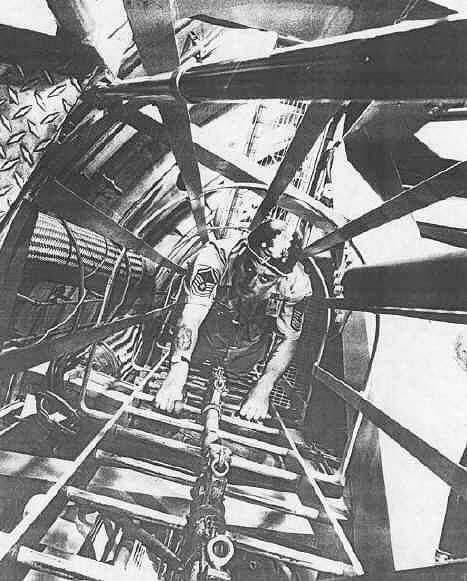

Now

where have I seen this before?

|

|

This

is not the exact same ladder as above which is also missing the safety

line and a Sergeant, but it shows how things used to look.

|

|

From

here on, the going gets really tough

|

More

cribwork to come in the next and final installment of the Missile Silo

sections.

Missile

Silos Part IX

|

Contact

| Site Map | Links |

Hosted by

InfoBunker