Silo

Construction

The

silos at the 724th and 725th SMS were 150' deep and 40' in diameter

and were constructed in multiple parts and pours of heavily reinforced

concrete.

The

top 35 feet or so was excavated using earth moving equipment such as

bulldozers and backhoes, and the remaining 115 feet were excavated

using a tractor with a front-end loader and a ripper on the back (see

photo below). As earth was excavated, a crane with a clam-shell

scoop removed the loose dirt.

PLEASE

NOTE: The images in this section are very high resolution

and may take a while to load. The images are much larger than

they are displayed here, so if you save and view them you can see

them at full resolution. Please be patient and enjoy the

details.

|

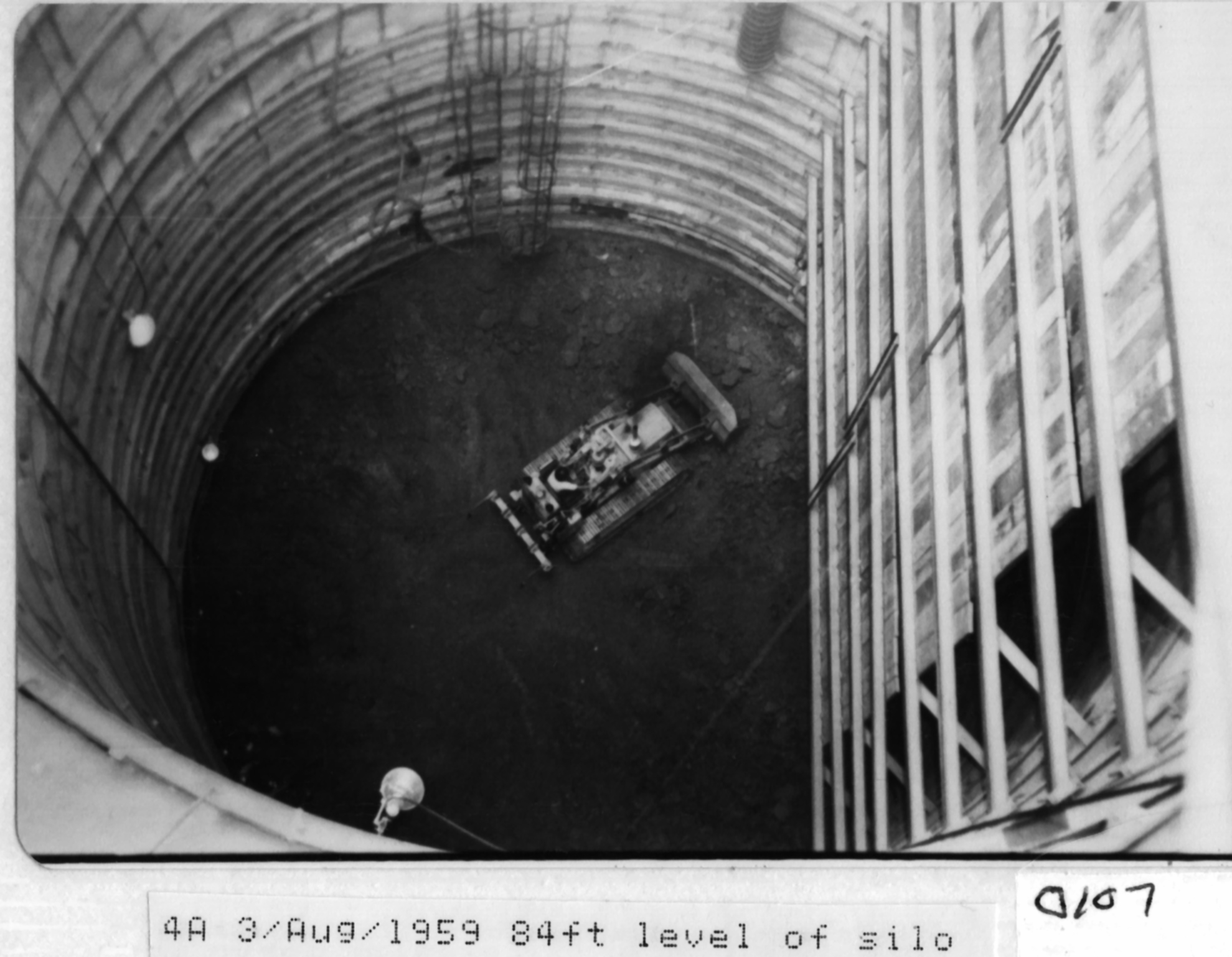

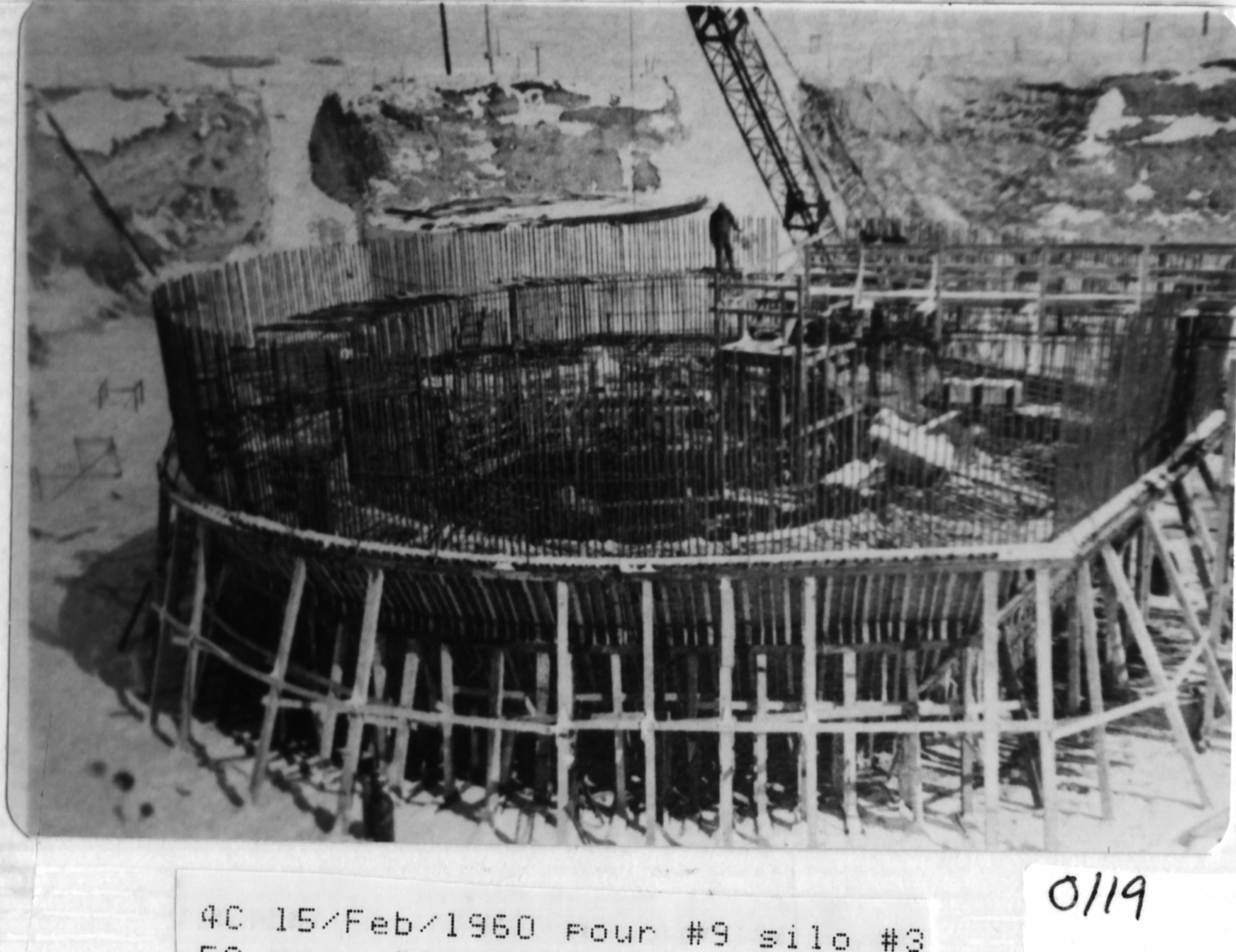

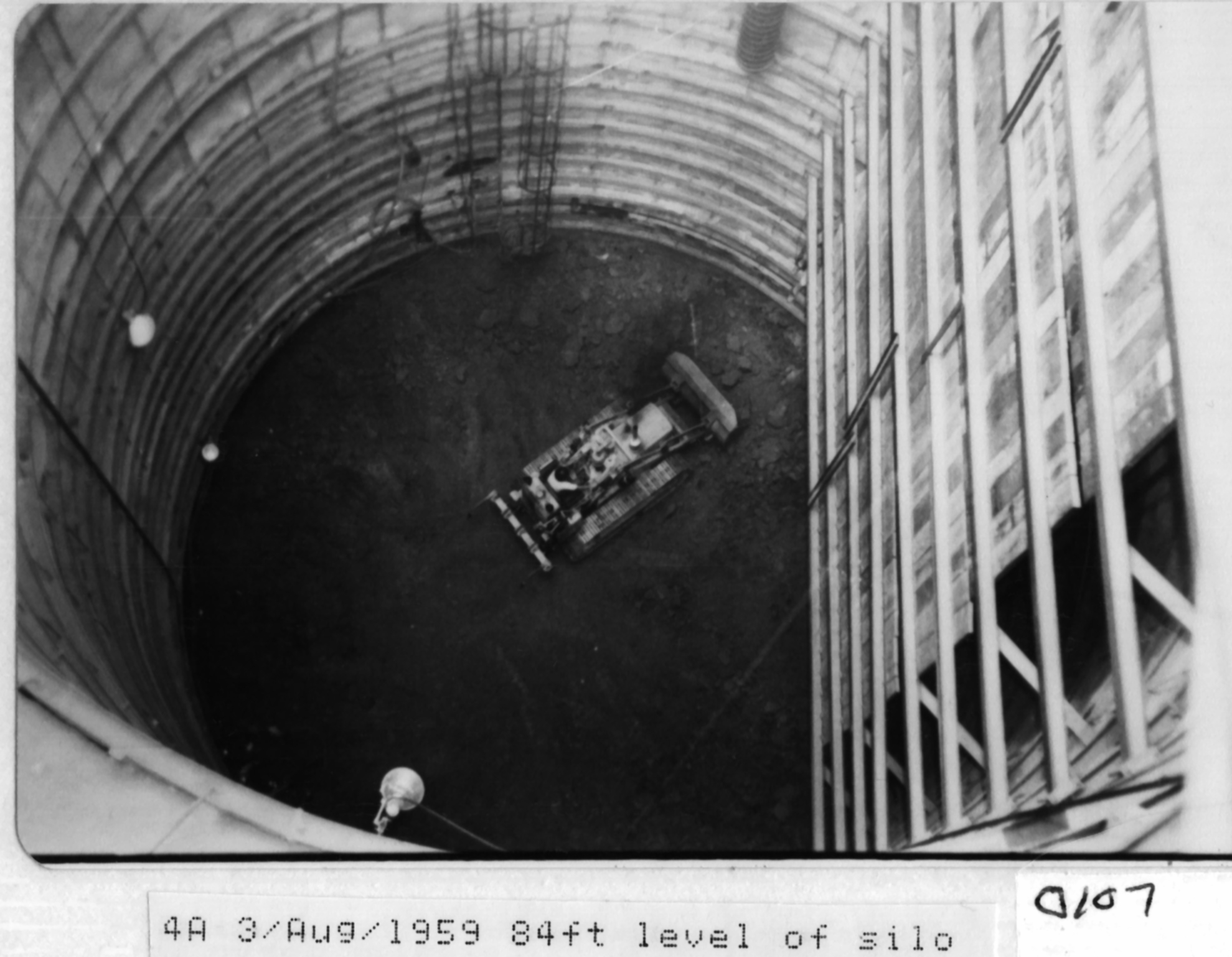

A

bulldozer excavating a silo. Loose earth was lifted out by a crane

Photo

courtesy of Fred Epler

|

The

raw dirt walls of the newly-excavated silos were sprayed with concrete

to prevent collapse until the complete depth was reached, at which

point slip forms were used to pour the permanent silo walls.

|

A

photo showing deeper excavation of a silo at the 724-A SMS. The

walls of the excavated silo were coated with gunite-- a spray-on

concrete, and then lined with steel ring beams to support the silo prior

to pouring the concrete walls.

Photo

courtesy of Fred Epler

|

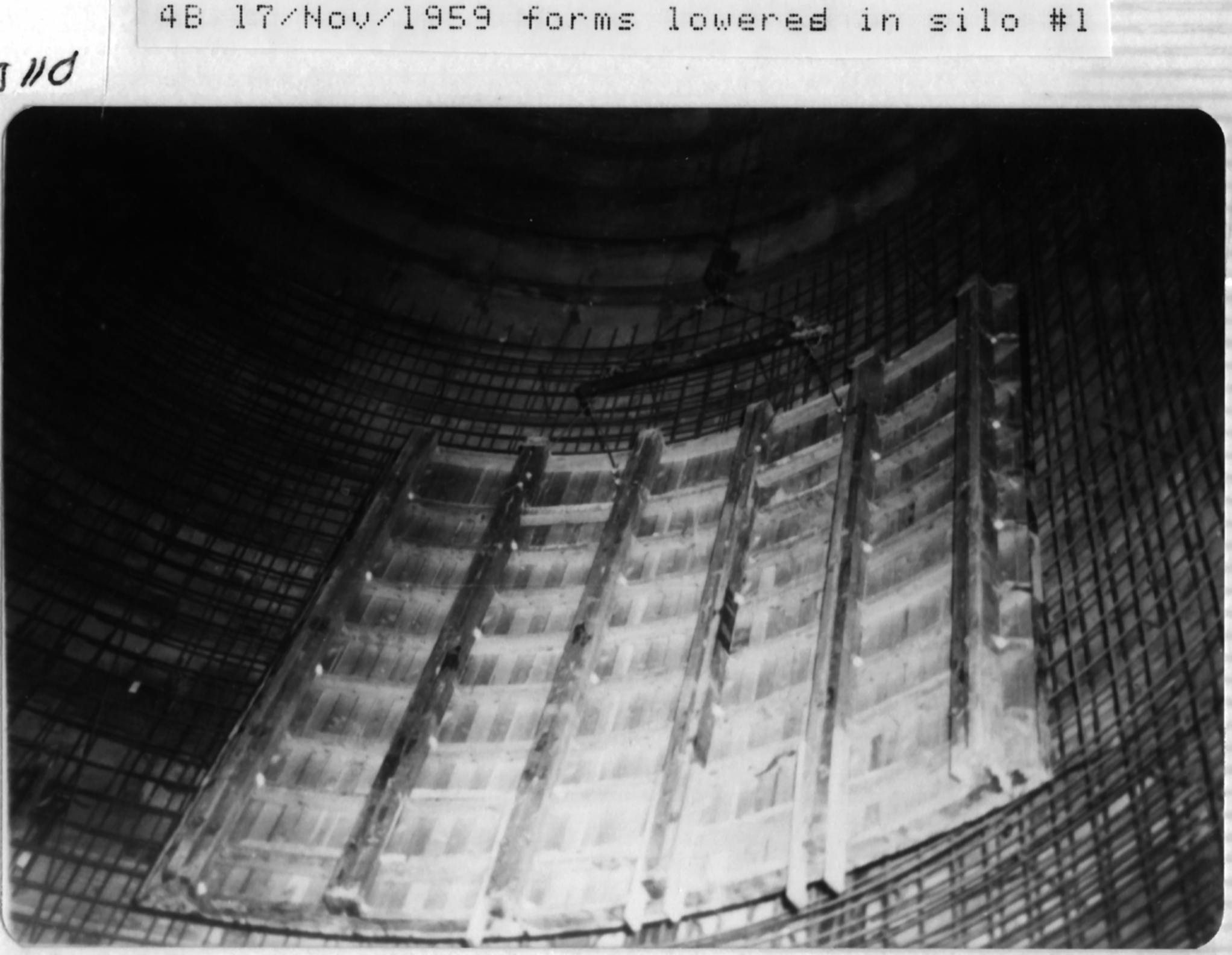

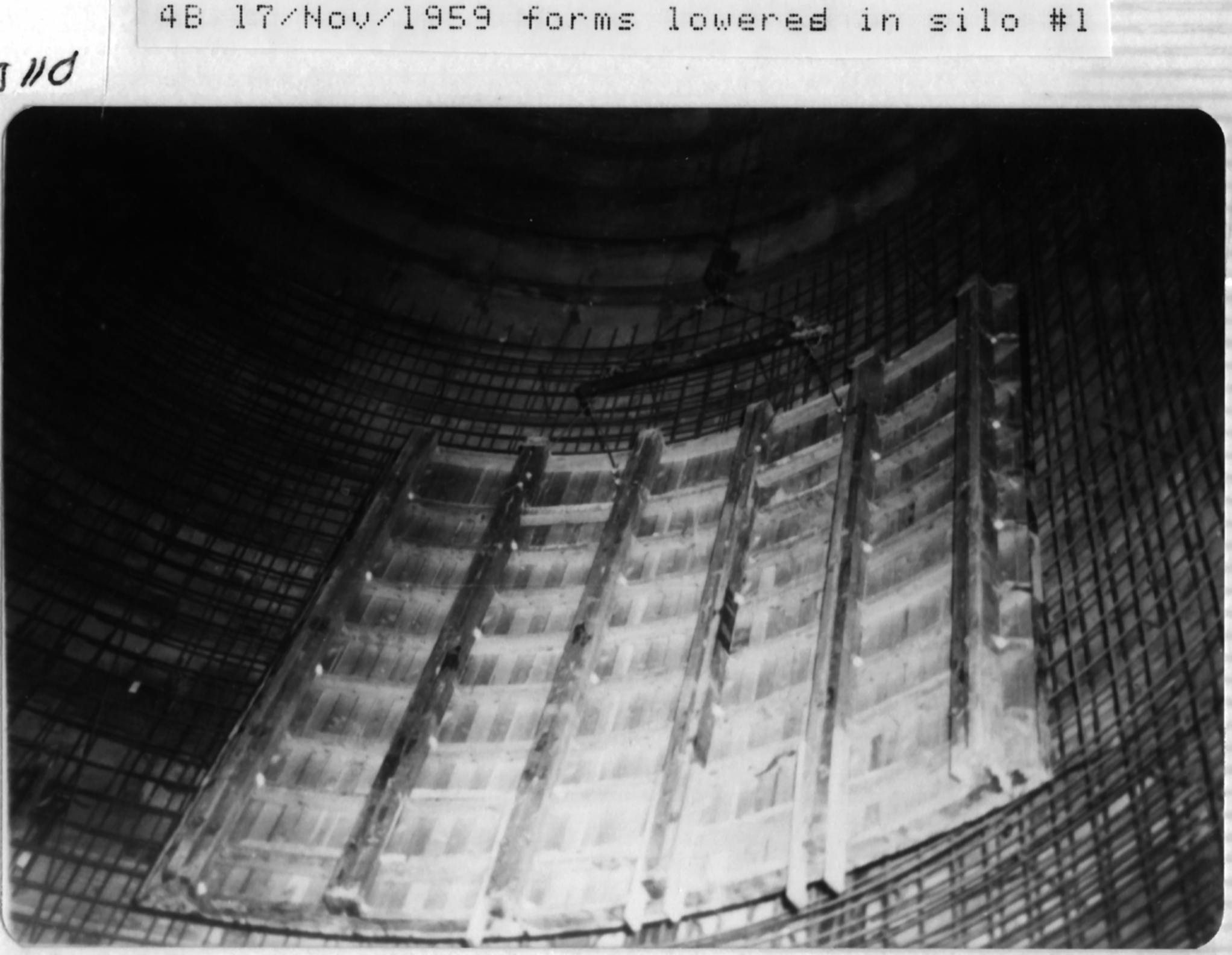

Below

is a photo showing the steel reinforcement complete and a form being

lowered into position. As the lower pours were completed, the

forms would be raised to pour the next section.

|

A

section of the concrete forms being emplaced for a pour at 724-B.

These forms were about 15 feet tall and after curing, the whole set of

forms were raised up for the next pour.

Photo

courtesy of Fred Epler

|

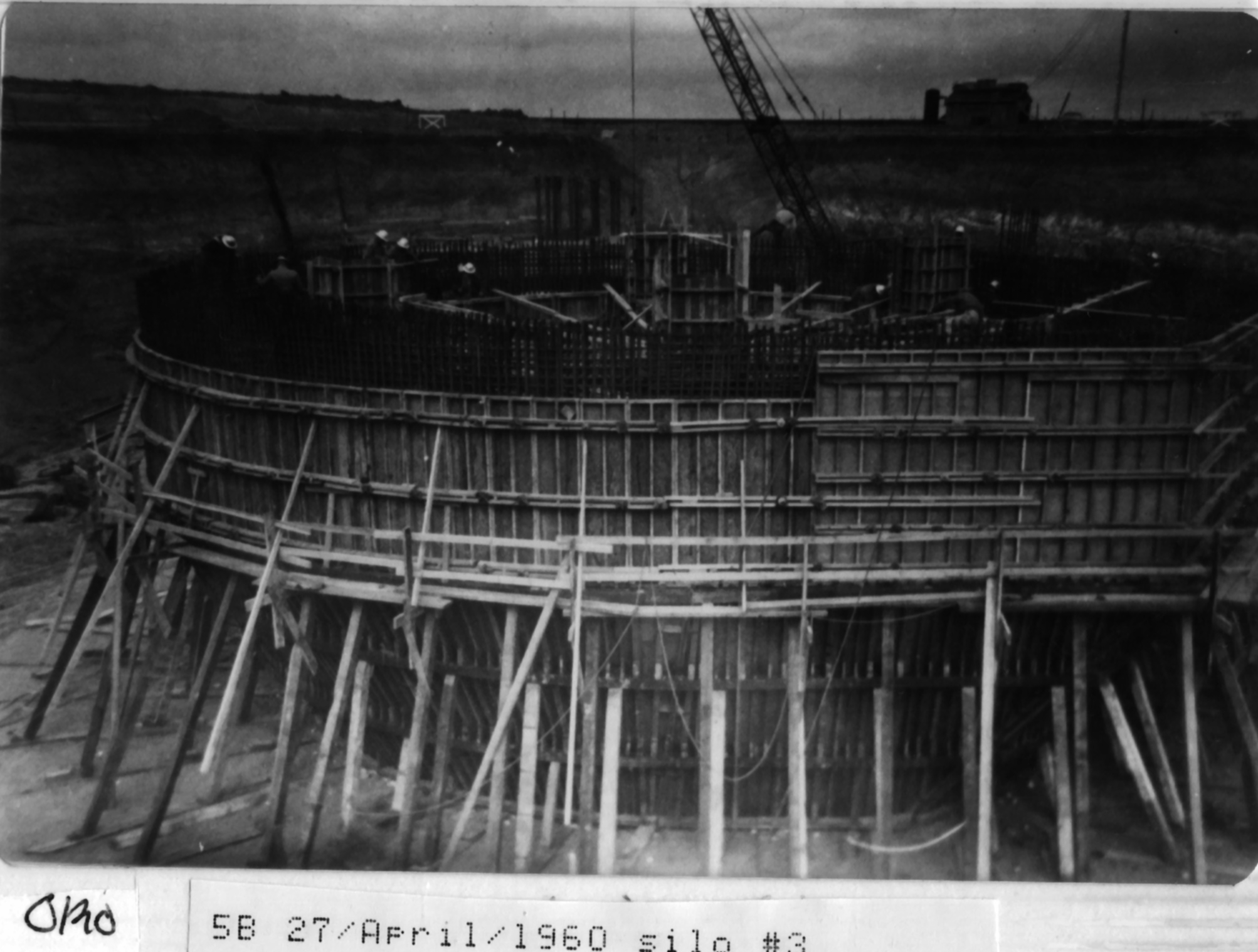

The

silo consisted of the solid lower portion and the top 35 feet, or cap,

which was a series of separate pours which were actually physically

separate from the lower portion of the silo. This was to both

prevent transfer of forces from the ground through the entire silo to

avoid damage and to allow some movement of the 2 sections relative to

each other in the case of a near-miss.

|

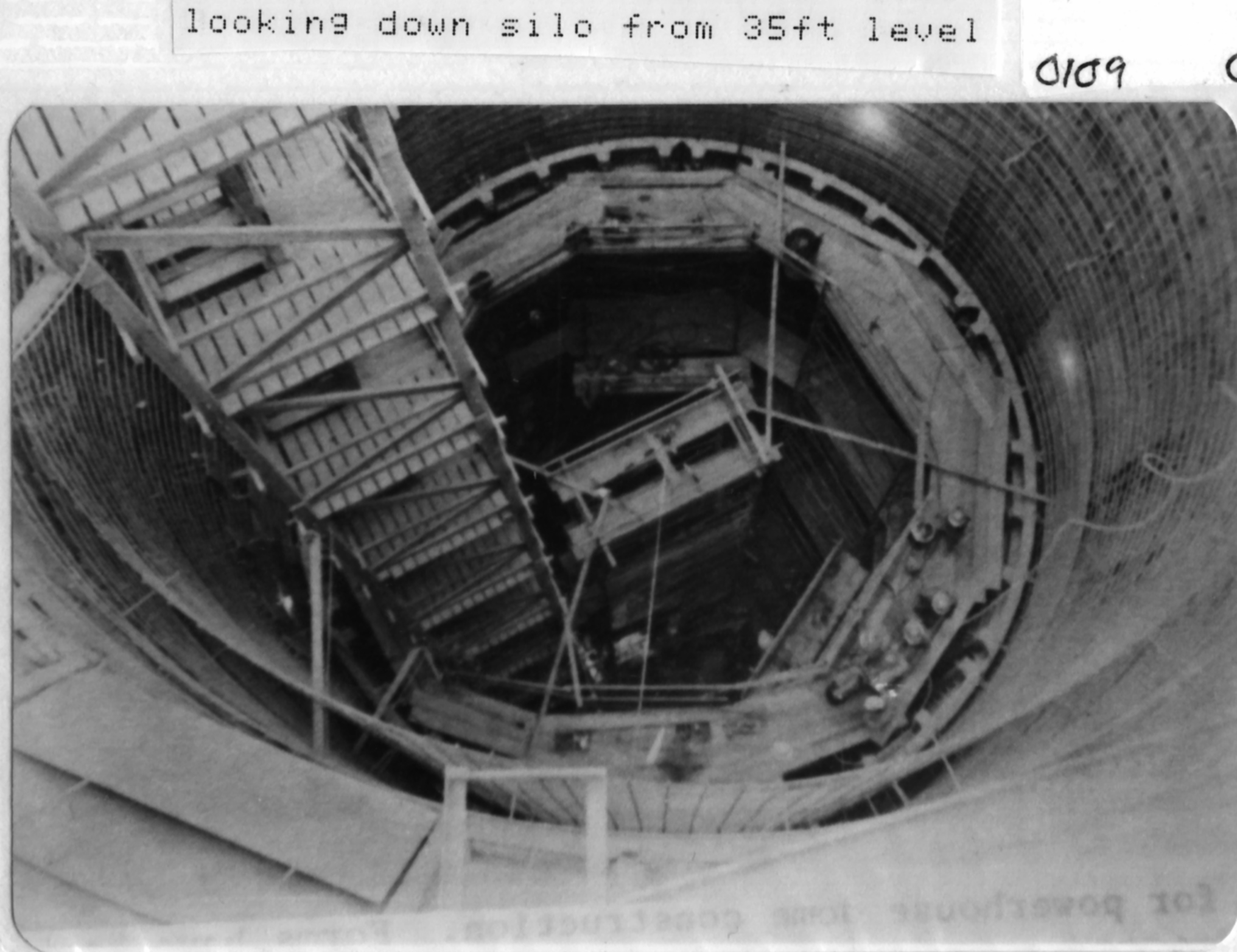

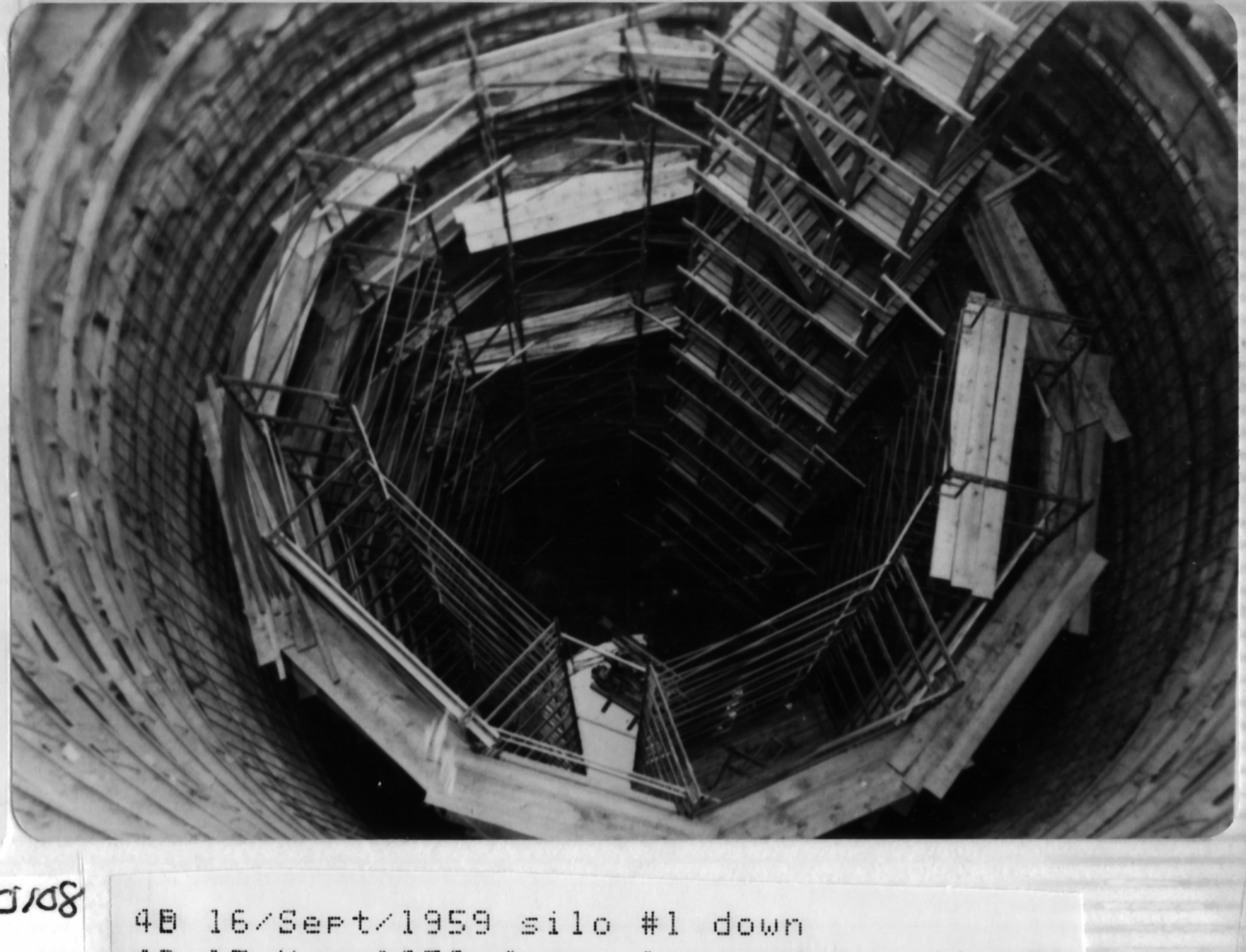

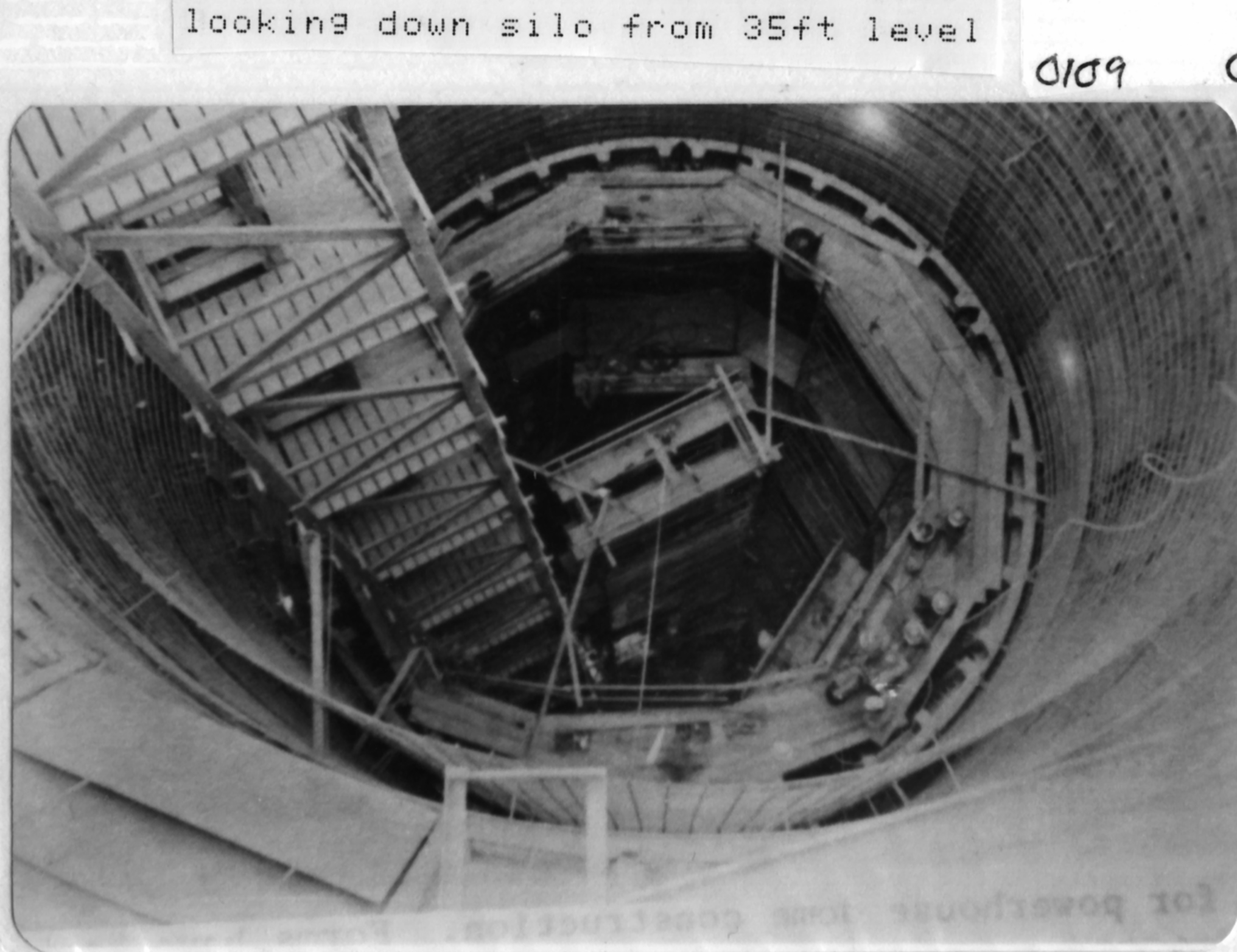

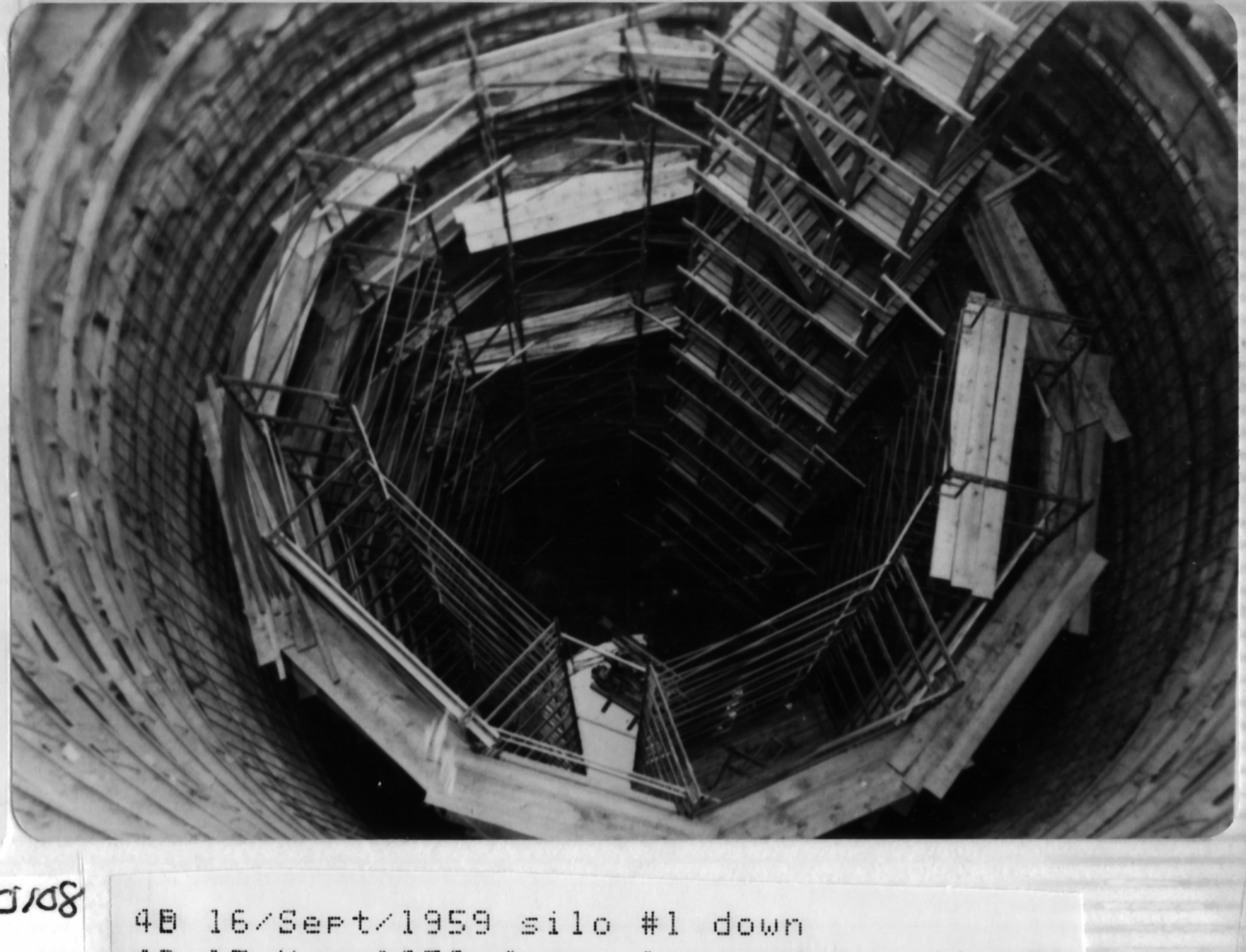

Scaffolding

and work platforms in place within an incomplete launcher silo. As

work was completed on the lower sections, other workers were able to

begin work on pipe hangers, fasteners and other structures and hardware

installed inside the silo.

Photo

courtesy of Fred Epler

|

|

Another

view of work platforms and scaffolding in launcher silo #1 at Lowry

complex 724-B.\

Photo

courtesy of Fred Epler

|

To

keep pace with the very demanding schedule, all silos were under

construction simultaneously. With all the workers on site, there

were few fatalities at the Lowry sites during construction. The

launcher silos were very dangerous areas to work, but the installation

of netting in the silos reduced the number of fatal accidents by

two-thirds.

In

all there were 3 fatalities during construction at the Lowry sites:

These

3 tragedies underscore the hazards involved in projects of such scale,

however it should be noted that the human toll of the Lowry Titan I

construction efforts were very low when compared to other such

projects. In fact, after July 15th 1960 there were no further

serious injuries and the safety record of the Lowry construction

projects was the best of the 5 areas where the Titans were

built. Over the entire project-- 1959 through 1961, there were

only 27 injuries that resulted in lost work hours at the Lowry sites.

|

Installing

safety netting in the silo.

At

the 6 Lowry complexes, this netting saved the life of 2 workers: a

carpenter who fell 90' and received only minor bruises, and a pipe fitter

who fell 70' receiving only an ankle injury. Both incidents surely

would otherwise have been fatal.

Photo

courtesy of Fred Epler

|

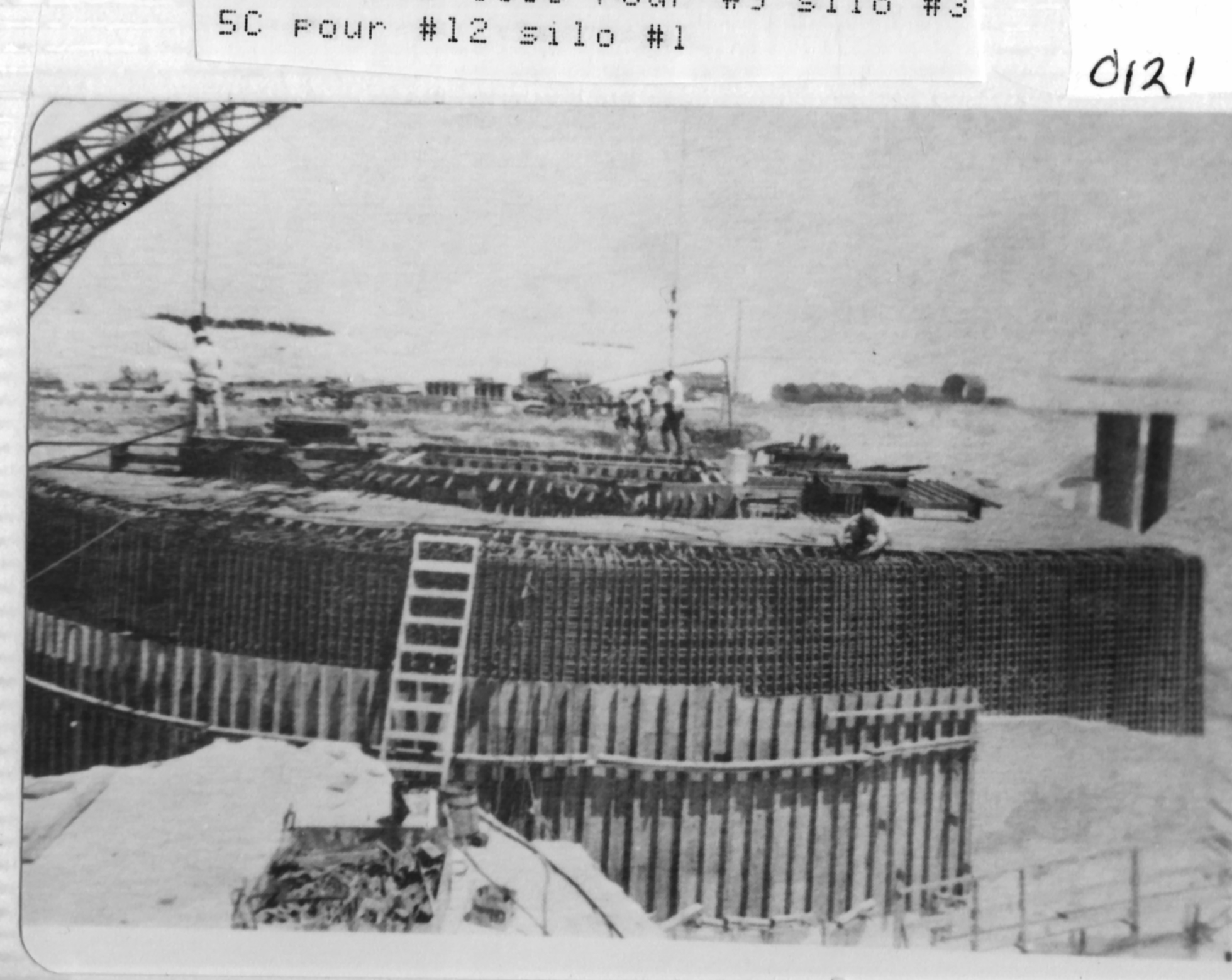

As

you can see in the following pictures the job of bending and

assembling the reinforcing steel was a massive one. Thousands of

tons of steel re-bar went into the construction of each silo.

Obviously, steel was crucial to a construction project of the size and

sort comprising a hardened underground missile facility. From a

scheduling standpoint this would become an insurmountable obstacle

early on.

The

greatest delay for construction of all the Lowry sites was due to a

nationwide steel workers strike lasting 114 days that began on July

14, 1959. Due to the unforeseen nature of this delay however,

the prime contractor, Morrison, Knudson & Associates was granted a

time extension to account for the lost 114 days where steel could not

be obtained at all.

As

a side note, the result of the 1959 steel workers' strike ushered in

the demand for foreign steel which had a profound negative effect on

the US steel industry.

|

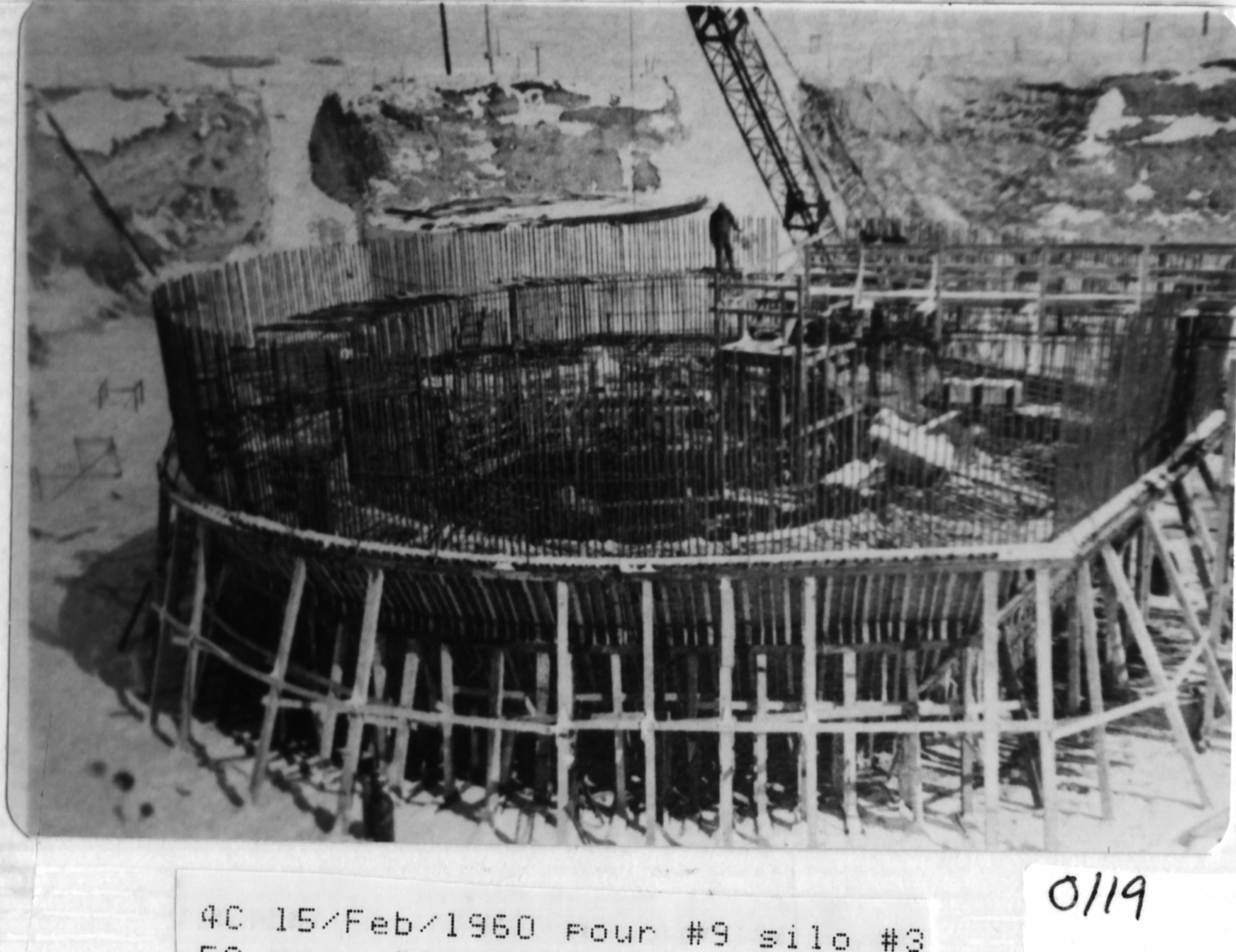

Forms

and reinforcement for the cap section of 724-C silo #3

Photo

courtesy of Fred Epler

|

|

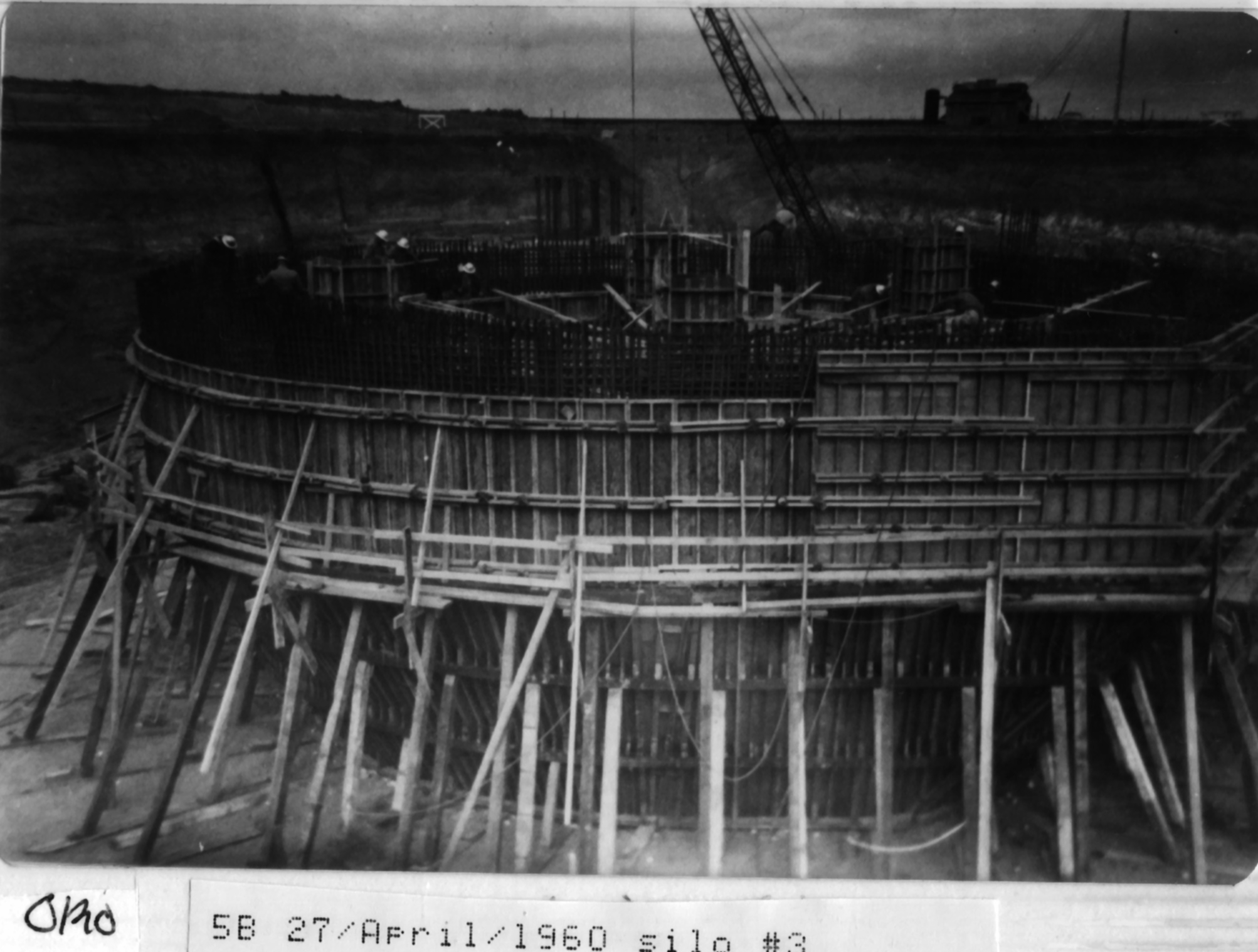

The

forms being placed for the final few pours. The concrete and steel

at the top of the cap are over 15 feet thick in places.

Photo

courtesy of Fred Epler

|

|

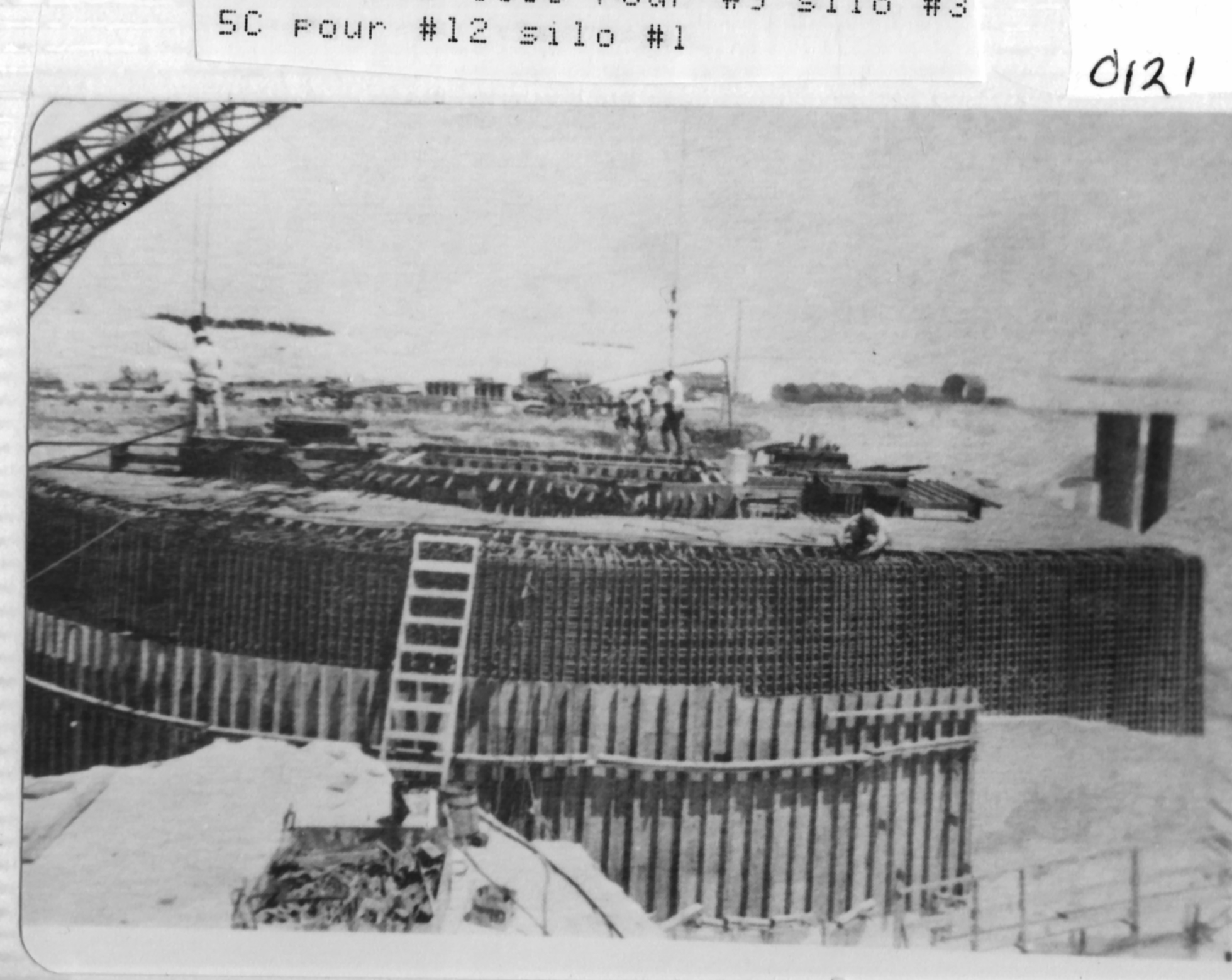

Preparing

for the final concrete pours comprising the silo cap. Note the

density of the steel reinforcement rods in the cap.

Photo

courtesy of Fred Epler

|

|

Pouring

concrete at 724-A silo #3

Photo

courtesy of Fred Epler

|

|

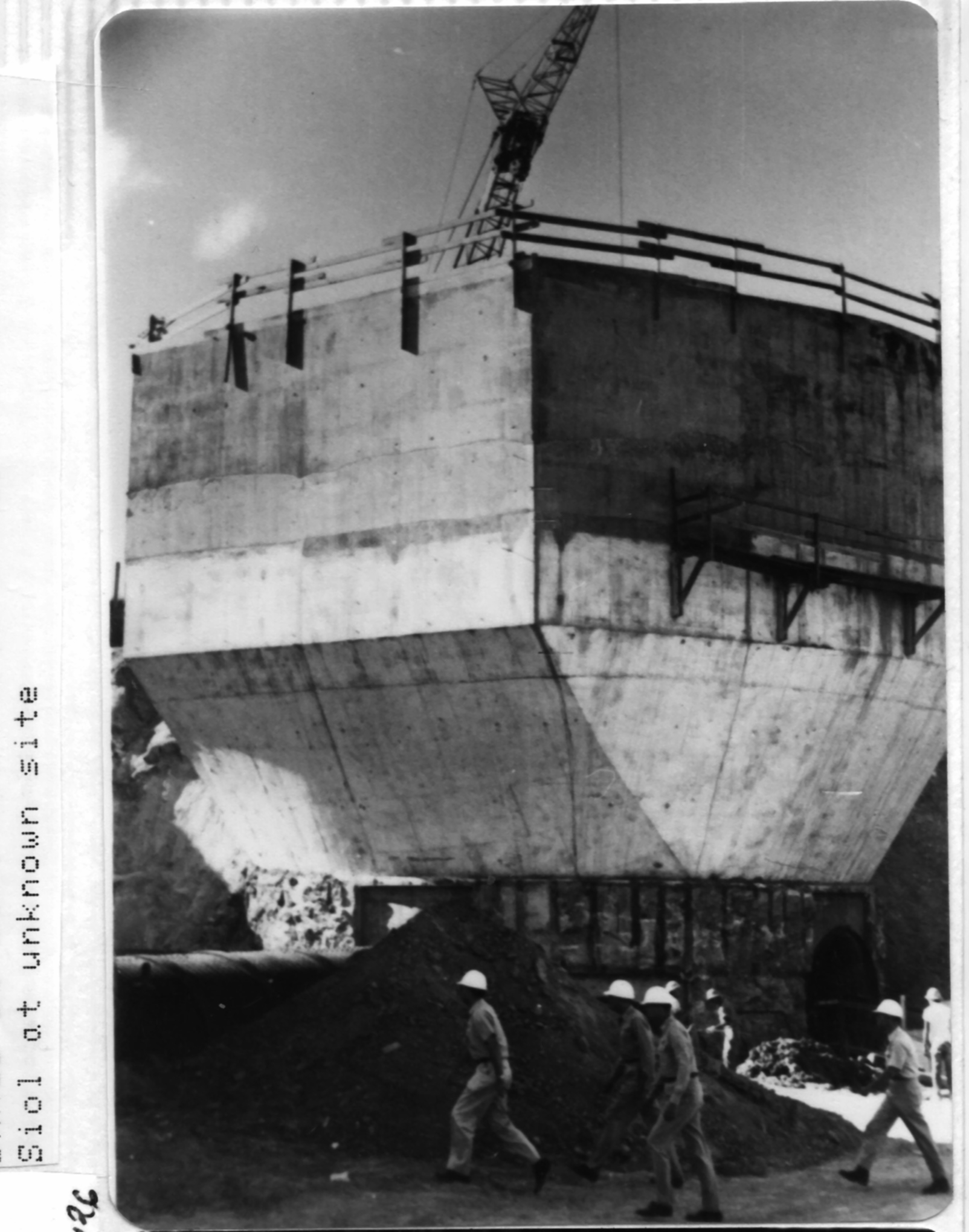

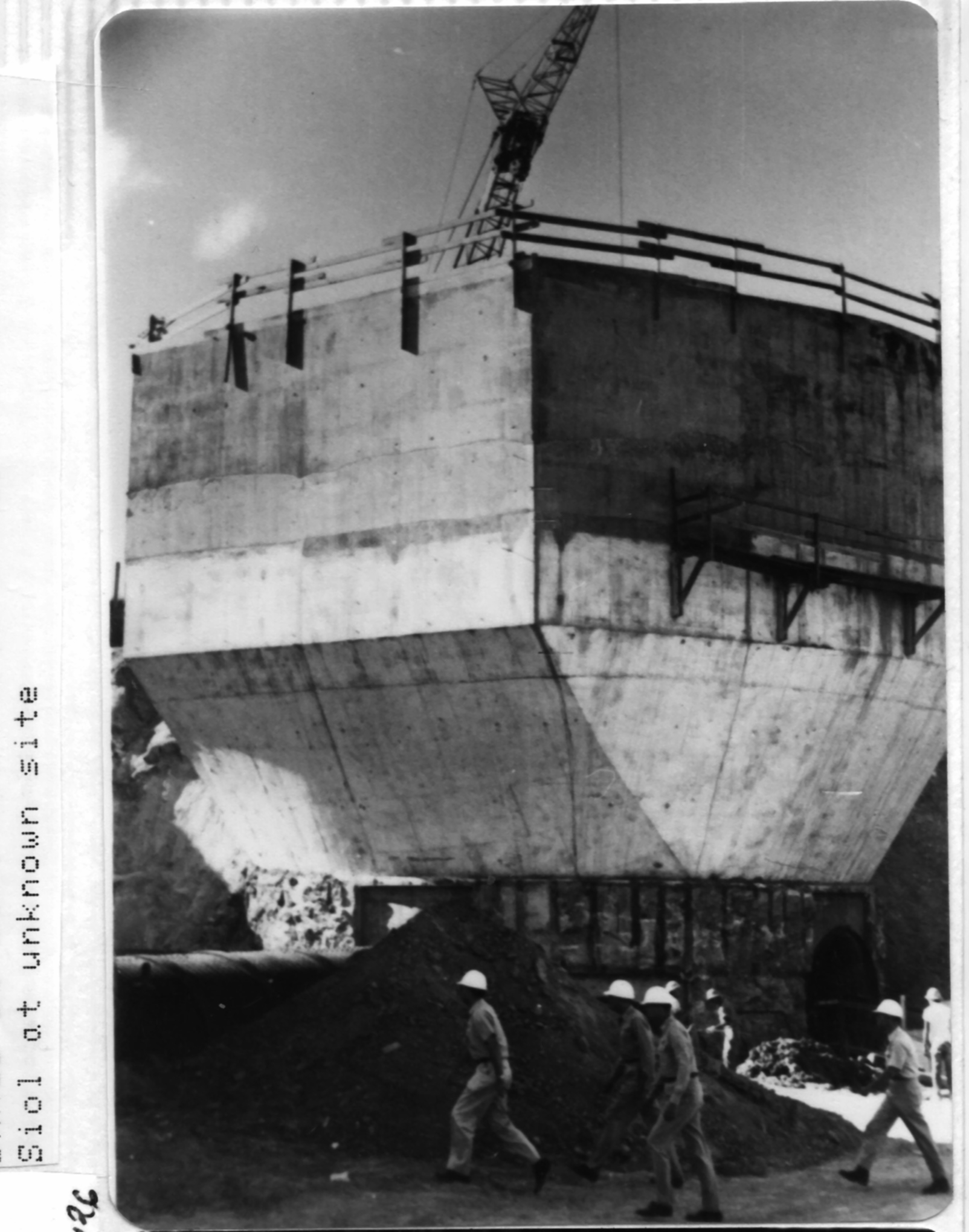

A

completed silo cap prior to backfilling

Photo

courtesy of Fred Epler

|

In

the next section, we'll look at just how insane the author of this

site can be when it comes to curiosity and defunct Cold War era

military installations. Click below to view my utter madness.

Missile

Silos Part IV

| Contact

|

Site Map | Links

|

Hosted by

InfoBunker